I-Technology Brazing Technology

I-Induction Brazing Principle | Inkolelo

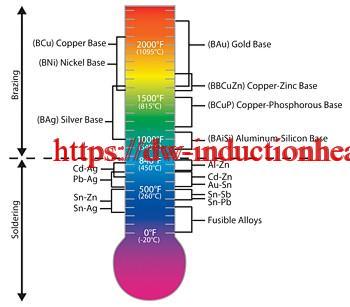

Ukubhanqa ne-soldering yizinqubo zokujoyina izinto ezifanayo noma ezingafani usebenzisa indaba ehambisanayo yokugcwalisa. Izitsha zensimbi zihlanganisa ukuhola, tin, ithusi, isiliva, i-nickel kanye nama-alloys azo. I-alloy kuphela iyancibilika futhi iqinisa phakathi nalezi zinqubo ukuze zijoyine izinto zokwakha zomsebenzi. I-filler metal itholwe ku-joint by action capillary. Izinqubo zokuxubha zenziwa ngezansi kwe-840 ° F (450 ° C) ngenkathi izinhlelo zokusebenza zokukhwabanisa zenziwa emazingeni okushisa ngaphezu kwe-840 ° F (450 ° C) kuze kufike ku-2100 ° F (1150 ° C).

Impumelelo yalezi zinqubo ixhomeke ekuklanyeni komhlangano, ukuhlukanisa phakathi kwezindawo okumele zihlangane, ukuhlanzeka, ukulawulwa kwenqubo kanye nokukhethwa okufanele kwemishini edingekayo ukuze kwenziwe inqubo ephindaphindiwe.

Ukuhlanzeka kuvamise ukutholakala ngokufaka uketshezi ohlanganisa futhi uchithe ukungcola noma ama-oxydes abawaxoshe ekuhlanganyeleni kwebhande.

Imisebenzi eminingi manje yenziwa endaweni elawulwayo ngengubo yegesi engena ngaphakathi noma inhlanganisela yamagesi angenalutho / asebenzayo ukuvikela ukusebenza nokuqeda isidingo sokugeleza. Lezi zindlela zifakazelwe ezinhlobonhlobo zezinto ezibonakalayo nezokulungiswa okuyingxenye okufaka esikhundleni noma ukuncoma ubuchwepheshe besithando somkhathi ngenqubo efanele yokuhamba kwesikhathi.

Izinto zokwenza izinto ze-brazing

Izinsimbi zensimbi ze-Brazing zingatholakala ngezindlela ezihlukahlukene, ubujamo, ubukhulu kanye nama-aloyi kuye ngokuthi kusetshenziswe kanjani. I-Ribbon, izindandatho ezenziwe ngaphambilini, unamathisele, ucingo kanye nama-washhers aguqulelwe ngaphambili nje nje ambalwa amafomu namafomu ama-alloys angatholakala.

Isinqumo sokusebenzisa i-alloy ethile kanye / noma ukuma ngokuyinhloko kuxhomeke ezintweni zokwakha umzali, ukubekwa ngesikhathi sokucubungula kanye nemvelo yesevisi okumele kwenziwe ngayo umkhiqizo wokugcina.

Ukususwa Kuthinta Amandla

Ukuhlukanisa phakathi kwezindawo zokuqhafaza okufanele zihlanganiswe kunquma inani le-braze alloy, isenzo se-capillary / ukungena kwe-alloy futhi ngemva kwalokho amandla okuhlanganyela okuphelile. Isimo esivumelana kahle kakhulu sezinhlelo zokusebenza ezivamile zesiliva zamasentimitha angu-0.002 (0.050 mm) kuya ku-0.005 mm (imvume ye-0.127 mm). I-aluminium ngokuvamile i-0.004 amasentimitha (0.102 mm) kuya ku-0.006 amasentimitha (0.153 mm). Izimvume ezinkulu kunamasentimitha angu-0.015 (0.380 mm) ngokuvamile azikho isenzo se-capillary esanele sebhande eliphumelelayo.

Ukubhincisa ngethusi (ngenhla kwe-1650 ° F / 900 ° C) kudinga ukubekezelelana okuhlangene kugcinwe okuncane kakhulu futhi kwezinye izimo ucindezeleke kahle emazingeni okushisa amancane ukuze kuqinisekiswe ukubekezelelana okungenani okuncane ngesikhathi sokushisa kwesibhakabhaka.

I-Induction Heating Theory

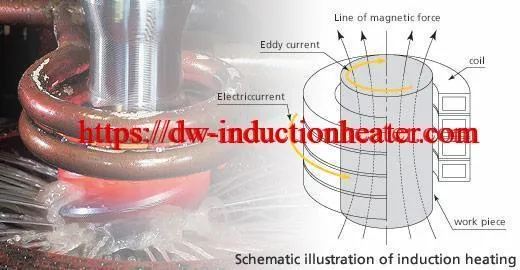

Izindlela zokungenisa izinto zinikeza indlela elula futhi eqondile yokushisa ngokushesha futhi ngempumelelo indawo ekhethiwe yomhlangano. Ukucatshangelwa kufanele kunikelwe ekukhethweni kwamandla okusebenza okuhlinzeka ngamandla, ubukhulu bamandla (i-kilowatt isetshenziswe ngamasentimitha ayisithupha), isikhathi sokushisa, nokuklanywa kwe-coil yokufakelwa ukuhlinzeka ukujula okudingekayo kokushisa kuhlangene othize.

Ukushisa kwe-Induction ukushisa okungaxhumani ngendlela ye-transformer theory. Ukunikezwa kwamandla ngumthombo we-AC ku-coil yokufakelwa okuba yi-winding eyinhloko ye-transformer ngenkathi ingxenye yokushisa iyona yesibili yomshini we-transformer. Isiqephu somsebenzi sishisa ngama-base materials 'okuyizinto zokugcina ugesi kagesi kuya kulokhu okwenziwe khona okugeleza emhlanganweni.

Ukudlula okwamanje ngomqhubi kagesi (umshini wokusebenza) kubangela ukushisa njengoba umanje uhlangana nokumelana nokugeleza kwawo. Lezi zilahleko ziphansi kwamanje ezigeleza nge-aluminium, ithusi kanye nama-alloys abo. Lezi zinto ezingezona ezensimbi zidinga amandla engeziwe okushisa kunabo abakwa-carbon steel counterpart.

I-current alternating iqala ukugeleza phezulu. Ubuhlobo obuphakathi kwemvamisa yamanje okwehlukile kanye nokujula okungena kulo mkhakha kuyaziwa ngokuthi ukujula kokubhekisisa kokushisa. Ingxenye yecala, uhlobo lwezinto ezibonakalayo kanye nobukhulu bodonga bungaba nethonya ekushiseni ukushisa ngokusekelwe ekujuleni kokubhekisela.