Kuyini ukukhishwa kwe-induction?

Ngokufakwa kwe-induction ukushisa kufakwa ngogesi ku-workpiece. Ijubane nokunemba

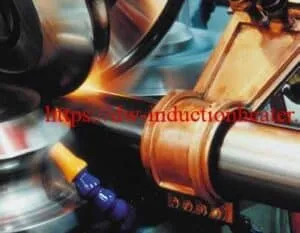

Welding induction yenza kube kuhle ekushiseni komphetho kwamashubhu namapayipi. Kule nqubo, amapayipi adlulisa ikhoyili yokungeniswa ngejubane elikhulu. Njengoba benza kanjalo, imiphetho yabo iyashiswa bese iyakhanywa ndawonye ukuze yakhe umsila we-weld longitudinal. Ukushiswa kwe-induction kufanelekile ikakhulukazi ekukhiqizeni okuphezulu. Ama-welding wokungeniswa nawo angafakwa emakhanda oxhumana nawo, uwaguqule abe

izinhlelo ezimbili zokulanda izinhloso.

Ziyini izinzuzo?

Ukushisela okuzenzakalelayo kwe-induction okuzenzakalelayo kuyinkqubo ethembekile, ephezulu kakhulu. Ukusetshenziswa kwamandla okuphansi nokusebenza kahle kwezinhlelo zokushisela ze-DAWEI kunciphisa izindleko. Ukulawulwa kwabo nokuphindeka kwabo kunciphisa udoti. Amasistimu ethu abuye aguquguquke — ukufaniswa kokulayishwa okuzenzakalelayo kuqinisekisa amandla okukhipha okugcwele kububanzi obuhlukahlukene bamashubhu. Futhi ukunyathela kwabo okuncane kwenza kube lula ukuhlanganisa noma ukuphinda kwenziwe kabusha emigqeni yokukhiqiza.

Kuphi lapho kusetshenziswa khona?

I-induction welding isetshenziswa embonini yethubhu nepayipi ekushiseni kwe-longitudinal yensimbi engagqwali (magnetic futhi non-magnetic), i-aluminium, i-low-carbon ne-highstrength low-alloy (HSLA) steels nezinye izinto eziningi ezihamba kahle

materials.

Ukuhlanganisa Insimbi neBrazing kanye neWelding

Ukuhlanganisa i-Metal ne-Brazing ne-Welding Kunezindlela eziningi zokuhlanganisa izinsimbi, kufaka phakathi i-welding, i-brazing ne-soldering. Uyini umehluko phakathi kokushisela nokubopha? Uyini umehluko phakathi kokubopha nokufaka i-soldering? Ake sihlole umehluko kanye nezinzuzo zokuqhathanisa kanye nezicelo ezijwayelekile. Le ngxoxo izokujulisa ukuqonda kwakho kwensimbi… Funda kabanzi