Ukuze kwandiswe ukusebenza kahle kanye nokunciphisa umphumela oshisayo wokushisa kwensimbi, i Ukukhishwa kwesibalo ubuchwepheshe buhlongozwayo. Inzuzo yalobu buchwepheshe itholakala ikakhulukazi endaweni eqondile yokushisisa okunikezwa amalunga abrazed. Ngokusekelwe emiphumeleni yokulingisa kwamanani kwase nokwenzeka ukuklama imingcele edingekayo ukuze kuzuzwe amazinga okushisa okubanda ngesikhathi osifunayo. Inhloso bekuwukunciphisa lesi sikhathi ukuze kugwenywe umphumela oshisayo ongathandeki ezinsimbi ngesikhathi sokuhlanganisa i-metallurgical..Imiphumela yokulingisa izinombolo yembula ukuthi ukukhulisa imvamisa yamanje kubangele ukugxilisana kwamazinga okushisa aphezulu ezindaweni ezingaphezulu kwezinsimbi ezihlanganisiwe. Ngokukhula kwamanje, ukuncishiswa kwesikhathi esidingekayo ukuze kufinyelelwe izinga lokushisa lokugqama kwabonwa.

Izinzuzo zokubeka i-induction brazing ye-aluminium vs. ithoshi noma ukubhsa kwelangabi

Izinga lokushisa eliphansi lokuncibilika lensimbi eyisisekelo ye-aluminium kuhlanganiswe newindi lenqubo yezinga lokushisa elincane lama-alloys e-braze asetshenziswayo kuyinselele lapho ithoshi likhanya. Ukushoda kokushintsha kombala ngenkathi i-aluminium yokushisisa ingabahlinzeki opharetha be-braze noma iyiphi inkomba ebonakalayo yokuthi i-aluminium isifinyelele izinga lokushisa elifanele lokubhula. Ama-opharetha e-Braze athula inani lezinto eziguquguqukayo lapho ikhanyisa ithoshi. Phakathi kwalokhu kuhlanganisa izilungiselelo zethoshi kanye nohlobo lomlilo; ibanga ukusuka ethoshi kuya ezingxenyeni ezishaywayo; indawo yelangabi elihlobene nezingxenye ezihlanganiswayo; futhi nokuningi.

Izizathu zokucabangela ukusebenzisa Ukushisa ukufakelwa lapho brazing aluminium zihlanganisa:

- Ukushisa okusheshayo, okusheshayo

- Ukulawula ukushisa okulawulwayo, okunembile

- Ukushisa okukhethiwe (okwasendaweni).

- Ukuguquguquka komugqa wokukhiqiza nokuhlanganiswa

- Impilo yemidlalo ethuthukisiwe nokuba lula

- Amalungu aphindaphindwayo, athembekile

- Ukuphepha okuthuthukisiwe

Ukuphumelela kwe-induction brazing yezingxenye ze-aluminium kuncike kakhulu ekwakhiweni ukufakwa kwezingxenye zokushisa ukugxilisa amandla okushisa ka-electromagnetic ezindaweni okufanele zigaywe futhi uzishise ngokufanayo ukuze ingxubevange ye-braze inyibilike futhi igeleze kahle. Amakhoyili angeniswayo aklanywe ngendlela engafanele angabangela ukuthi ezinye izindawo zishise ngokweqile kanti ezinye izindawo zingatholi amandla okushisa anele okuholela ekuhlanganeni kwe-braze okungaphelele.

Ngejoyinti yeshubhu ye-aluminium brazed evamile, isisebenzisi sifaka iringi ye-aluminium braze, evame ukuqukatha i-flux, kushubhu ye-aluminium bese ifaka lokhu kwelinye ishubhu elinwetshiwe noma i-block fitting. Izingxenye zibe sezifakwa kukhoyili yokungeniswa bese zishiswa. Ngenqubo evamile, izinsimbi zokugcwalisa i-braze ziyancibilika futhi zigeleze zingene esibonakalayo esihlanganyelwe ngenxa yesenzo se-capillary.

Kungani i-induction braze vs. torch braze aluminium components?

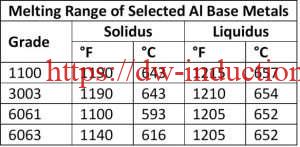

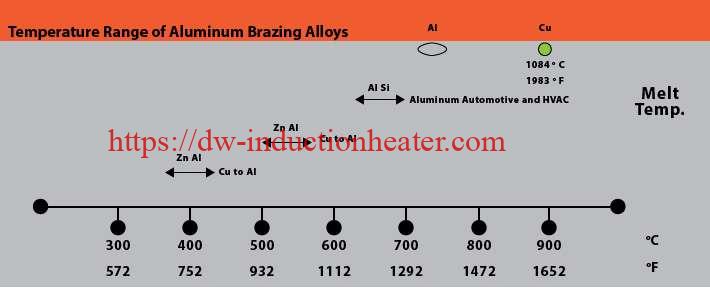

Okokuqala, ingemuva elincane lama-alloys e-aluminium avamile avamile namuhla kanye ne-aluminium braze evamile namasoda asetshenziselwa ukujoyina. Izingxenye ze-aluminiyamu ze-brazing ziyinselele kakhulu kunezinsimbi zethusi zokubhula. Ithusi liyancibilika ku-1980°F (1083°C) futhi lishintsha umbala njengoba lishiselwa. Ama-alloys e-aluminium avame ukusetshenziswa ezinhlelweni ze-HVAC aqala ukuncibilika cishe ku-1190°F (643°C) futhi awanikezi noma yiziphi izimpawu ezibonakalayo, ezifana nokushintsha kombala, njengoba kushisa.

Kudingeka ukulawulwa kwezinga lokushisa okunembe kakhulu njengomehluko wamazinga okushisa ancibilikayo kanye nokugqama kwe-aluminium, kuncike kusisekelo sensimbi ye-aluminium, insimbi yokugcwalisa i-braze, nesisindo sezingxenye okufanele zigaywe. Isibonelo, Umehluko wezinga lokushisa phakathi kwezinga lokushisa eliqinile lama-alloy amabili avamile e-aluminium, i-aluminium engu-3003 yochungechunge, ne-aluminium yochungechunge engu-6061, kanye nezinga lokushisa loketshezi le-BAlSi-4 braze alloy elisetshenziswa njalo lingu-20°F – iwindi lenqubo lokushisa elincane kakhulu, ngakho kudingeka ukulawula okunembile. Ukukhethwa kwama-base alloys kubaluleke kakhulu ngezinhlelo ze-aluminium eziqiniswayo. Umkhuba ongcono kakhulu uwukubanda ezingeni lokushisa elingaphansi kwezinga lokushisa eliqinile lama-alloys okwenza izingxenye zihlanganiswe ndawonye.

| AWS A5.8 Ukuhlelwa | Ukwakheka Kwamakhemikhali Okuzisholo | I-Solidus °F (°C) | I-Liquidus °F(°C) | I-Brazing Temperature |

| BAISI-3 | 86% Al 10%Si 4%Cu | 970 (521) | 1085 (855) | 1085~1120 °F |

| BAISI-4 | 88% aL 12%Si | 1070 (577) | 1080 (582) | 1080~1120 °F |

| 78 Zn 22%Al | 826 (441) | 905 (471) | 905~950 °F | |

| 98% Zn 2%Al | 715 (379) | 725 (385) | 725~765 °F |

Kumele kuqashelwe ukuthi ukugqwala kwe-galvanic kungenzeka phakathi kwezindawo ezicebile zinc kanye ne-aluminium. Njengoba kuphawuliwe eshadini le-galvanic kuMfanekiso 1, i-zinc ayihlonipheki kangako futhi ijwayele ukuba yi-anodic uma iqhathaniswa ne-aluminium. Ukuncipha komehluko ongaba khona, izinga lokugqwala liyancipha. Umehluko ongaba khona phakathi kwe-zinc ne-aluminium mncane kakhulu uma kuqhathaniswa namandla phakathi kwe-aluminium nethusi.

Esinye isenzakalo lapho i-aluminium igaywa nge-alloy ye-zinc i-pitting. Iseli yendawo noma ukugqwala komgodi kungenzeka kunoma iyiphi insimbi. I-aluminiyamu ivamise ukuvikelwa ifilimu eliqinile, elincanyana elakheka phezulu lapho lichayeka kumoya-mpilo (i-aluminium oxide) kodwa lapho uketshezi oluphumayo lususa lesi singqimba se-oxide esivikelayo, ukuhlakazeka kwe-aluminium kungenzeka. Uma insimbi yokugcwalisa ihlala isikhathi eside incibilikile, ukuncibilika kuba nzima kakhulu.

I-Aluminium yakha ungqimba oluqinile lwe-oxide ngesikhathi sokubhula, ngakho-ke ukusetshenziswa kwe-flux kubalulekile. Izingxenye ze-aluminium eziguquguqukayo zingenziwa ngokuhlukana ngaphambi kokubhula noma i-aluminium brazing alloy equkethe i-flux ingafakwa enqubweni yokubhoboza. Kuye ngohlobo lokuguquguquka okusetshenzisiwe (okugqwalayo uma kuqhathaniswa nokungagqwali), isinyathelo esengeziwe singase sidingeke uma insalela ye-flux kufanele ikhishwe ngemva kokubhula. Xhumana nomkhiqizi we-braze kanye ne-flux ukuze uthole izincomo mayelana ne-brazing alloy kanye nokuguquguquka okusekelwe ezintweni ezihlanganiswayo kanye namazinga okushisa okushisa alindelekile.