Induction Annealing Brass Bullet Shells Heating Treatment UHF Series Nge-Induction Heating System

Inhloso Yohlelo Lokusebenza:

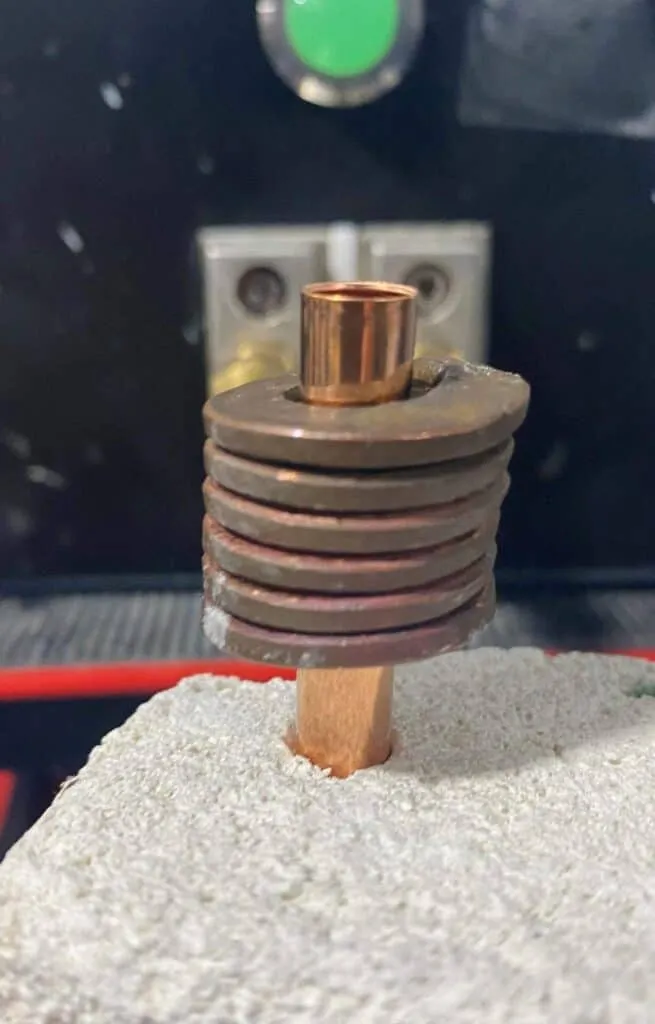

I-manufacturamagobolondo enhlamvu yethusi afuna ukuwenza thuthukisa yabo ekhona imishini yokushisa yokufakelwa futhi ifuna ukusebenza okuthuthukile. Gi-oal kwalokhu kuhlolwa kohlelo lokusebenza ukukhombisa ukuthi i Uhlelo lwe-DW-UHF-6KW-III lokungeniswa izohlangabezana futhi idlule izidingo zayo zokuzuza ngcono izikhathi zokushisa nokugcina ukufana kokushisa ngaphakathi kwendawo eqondisiwe. Two osayizi of zethusi izinhlamvu amagobolondo zisetshenziselwe isivivinyo - bulasing bezinhlamvus nge 1.682 " (42.7 mm) ubude futhi 0.929" (23.5 mm) ubude. Isikhathi esihlosiwe sokuncishwa yi-0.6 imizuzwana kuzo zombili izingxenye usebenzisa ukushisa okukodwa kokungeniswa coil.

I-HLQ DW-UHF-6kW-III ipholile emoyeni Ukushisa ukufakelwa uhlelo was kusetshenzisiwe enkambisweni yokuncishiswa. I-Tempilaq ukudweba yayisetshenziselwa inqume uma ngabe oyifunayo lokushisa endaweni efakwe umgodi kufinyelelwa kuyo.

Inqubo:

Amagobolondo enhlamvu yethusi abekwe endaweni ye- ukufakwa kwe-coil yokushisa. Indawo ezokwengezwa kabusha took cishe ama-60% wobude bengxenye abalwa kusukela ekugcineni okuvulekile. The Indawo efudunyeziwe yayipendiwe nge I-Tempilaq yiluphi usizoed us hlola izinga lokushisa ukusatshalaliswa. Zombili izingxenye zifinyelele ngempumelelo ekushiseni okukhonjiwe of 750 °F (398° C) ngo-0.6sec. Ngoba the ingxenye encane, amandla kagesi ancishiswa aba ngu-45% ukuvimbela the ukushisa kwengxenye.

I-Annealing ye-Induction

Ngokuvamile, inhloso enkulu yokwenziwa kokufakwa kokushisa okushisayo ukuthambisa insimbi, ukuvuselela izakhiwo zensimbi ezishise ngokweqile noma nje ukususa ukungezwani kwangaphakathi.

Ngokuyisisekelo iqukethe ukufudumeza kushushu lokushisa (800ºC kanye no-950ºC kuya ngohlobo lwensimbi), kulandelwe ukupholisa okuhamba kancane.

I-Annealing ye-Induction inqubo yokwelashwa kokushisa okubandakanya ukufudumeza impahla ngaphezu kokushisa kwayo kokuphinda kufakelwe kabusha. Inhloso ukufinyelela nokugcina ukushisa okufanelekile isikhathi esanele okulandelwa ukupholisa okufanele. Imvamisa isetshenziswa ekusetshenzisweni kwensimbi nakwisayensi yezinto ezibonakalayo ukwenza ukuthi isampuli ephathwayo isebenzeke kakhudlwana ngokunciphisa ubulukhuni bayo nokwandisa ukuthambeka kwayo (ikhono lokushintsha ifomu ngaphandle kokuphuka).

I-Annealing iguqula isimo somzimba futhi kwesinye isikhathi amakhemikhali alokho okusetshenziswayo njengokuphinda kufakelwe kabusha kutholakala ngesikhathi sokupholisa. Ngakho-ke, izakhiwo eziphumayo zama-alloys amaningi, kufaka phakathi i-carbon steel, zombili zincike ekushiseni nasezingeni lokupholisa. Izinsimbi eziyinsimbi, ezinjengensimbi, zidinga ukupholisa okuhamba kancane ukuze kufinyelelwe. Ezinye izinto (isib. Ithusi, isiliva) zingapholiswa kancane emoyeni noma zicishwe ngokushesha emanzini.

Ukushisa kwe-induction kunikeza ukulawula okuthuthukile kwenqubo yokuncishwa. Amaphrofayli wokushisa aphindaphindiwe angatholakala kalula ngokulawulwa okuqondile kwamandla okushisa. Njengoba i-workpiece ishiswa ngqo ngamandla kazibuthe, impendulo esheshayo ingatholakala. Ngaphezu kwalokho, ukusebenza kahle okuphelele kwenqubo yokufudumeza kokungeniswa kubalulekile ekwelashweni okude kangako.

Uma kuqhathaniswa nezindlela eziningi ezijwayelekile, ukungeniswa kwe-induction kuyindlela ehlanzekile futhi elula yokwenza, engenakuxhumana nokuhlinzeka ngekhwalithi ephezulu yezinto zokusebenza eziphathwayo.

Izinzuzo zokungenisa ukufudumeza

- Kucutshungulwe ngokuhambisana nokulawulwa kwamapharamitha ngesikhathi sangempela

- Imiphumela yensimbi efana naleyo etholakala kuhhavini ojwayelekile

- Ukungcoliswa kwemvelo okuncane

- Khulisa ukusebenza kahle kwamandla

- Isikhathi sokucubungula esinciphile

- Amandla okulawula ukushisa, ukunemba kokushisa

- Amandla okushisa izindawo ezincane ngaphandle kokushintsha izici zayo yonke ingxenye

- Umjikelezo wokushisa okunembile nokuphindaphindwayo

- Ukuncipha kwe-oxidation ebusweni

- Isimo semisebenzi esithuthukisiwe

Ezinye izimboni ezihlobene nazo yipayipi nepayipi, imithi, uwoyela negesi nezimoto.