I-HLQ Izindlela zokushisa zokushisa ziyizinhlelo ezingezwe zenani ezingangena ngqo kuseli lokukhiqiza, zinciphise isikhuhla, imfucuza, futhi ngaphandle kwesidingo sezitobha. Amasistimu angahle enzelwe ukulawulwa okwenziwa ngesandla, okuzenzakalelayo okuzenzakalelayo, nayo yonke indlela eya ezinhlelweni ezisebenza ngokuphelele. I-HLQ induction brazing kanye nezinhlelo ze-soldering ziphinda zinikeze amalunga ahlanzekile, angavuza ahlukahlukene wezingxenye ezibandakanya imigqa yamafutha, abashintshi bokushisa, abasabalalisi begesi, abasebenza ngezinto eziningi, ithuluzi le-carbide, nokuningi.

Izimiso ze-Induction Brazing & Soldering

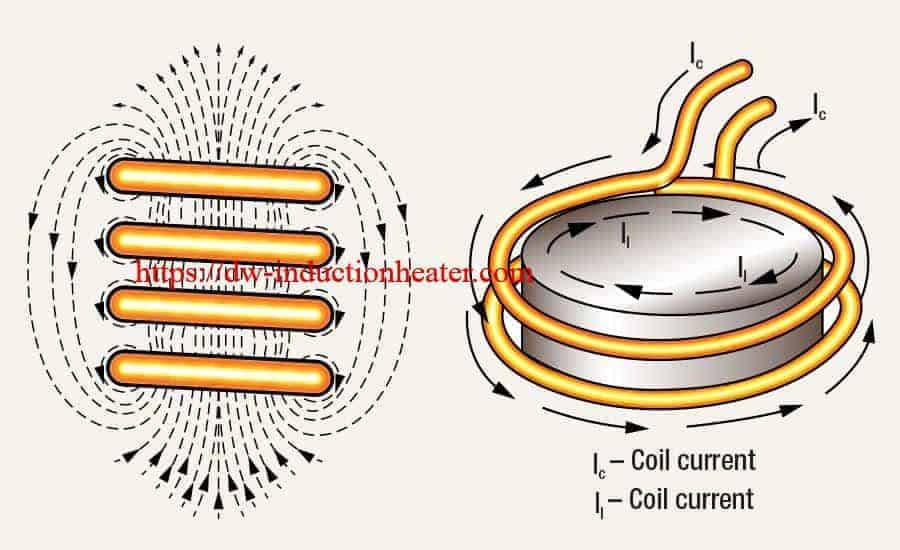

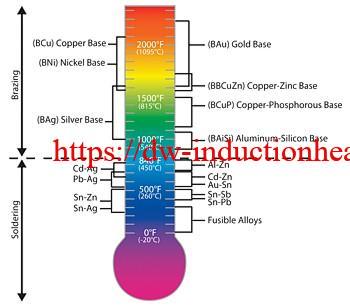

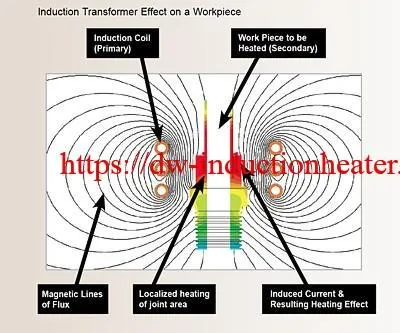

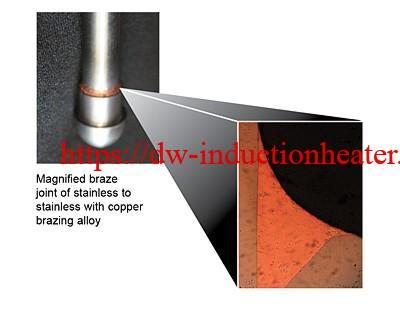

Ukubhanqa ne-soldering yizinqubo zokujoyina izinto ezifanayo noma ezingafani usebenzisa indaba ehambisanayo yokugcwalisa. Izitsha zensimbi zihlanganisa ukuhola, tin, ithusi, isiliva, i-nickel kanye nama-alloys azo. I-alloy kuphela iyancibilika futhi iqinisa phakathi nalezi zinqubo ukuze zijoyine izinto zokwakha zomsebenzi. I-filler metal itholwe ku-joint by action capillary. Izinqubo zokuxubha zenziwa ngezansi kwe-840 ° F (450 ° C) ngenkathi izinhlelo zokusebenza zokukhwabanisa zenziwa emazingeni okushisa ngaphezu kwe-840 ° F (450 ° C) kuze kufike ku-2100 ° F (1150 ° C).

Impumelelo yalezi zinqubo ixhomeke ekuklanyeni komhlangano, ukuhlukanisa phakathi kwezindawo okumele zihlangane, ukuhlanzeka, ukulawulwa kwenqubo kanye nokukhethwa okufanele kwemishini edingekayo ukuze kwenziwe inqubo ephindaphindiwe.

Impumelelo yalezi zinqubo ixhomeke ekuklanyeni komhlangano, ukuhlukanisa phakathi kwezindawo okumele zihlangane, ukuhlanzeka, ukulawulwa kwenqubo kanye nokukhethwa okufanele kwemishini edingekayo ukuze kwenziwe inqubo ephindaphindiwe.

Ukuhlanzeka kuvamise ukutholakala ngokufaka uketshezi ohlanganisa futhi uchithe ukungcola noma ama-oxydes abawaxoshe ekuhlanganyeleni kwebhande.

Induction Brazing Filler Izinto zokusebenza

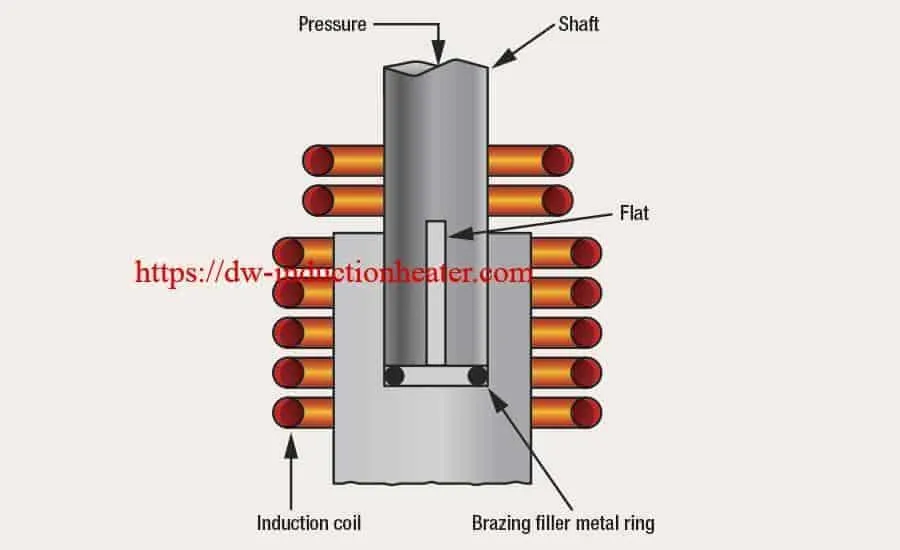

I-Induction Brazing filler metals ingeza ngezindlela ezahlukahlukene, bobunjwa, osayizi kanye nama-alloys ngokuya ngokusetshenziswa kwabo okuhlosiwe. I-Ribbon, izindandatho ezisetshenzisiwe ngaphambili, unamathisela, i-wire kanye ne-washers esetshenzisiwe ngaphambili imbalwa nje yezimo namafomu alloys angatholakala.

Isinqumo sokusebenzisa i-alloy ethile kanye / noma ukuma ngokuyinhloko kuxhomeke ezintweni zokwakha umzali, ukubekwa ngesikhathi sokucubungula kanye nemvelo yesevisi okumele kwenziwe ngayo umkhiqizo wokugcina.

Imisebenzi eminingi manje yenziwa endaweni elawulwayo ngengubo yegesi engena ngaphakathi noma inhlanganisela yamagesi angenalutho / asebenzayo ukuvikela ukusebenza nokuqeda isidingo sokugeleza. Lezi zindlela zifakazelwe ezinhlobonhlobo zezinto ezibonakalayo nezokulungiswa okuyingxenye okufaka esikhundleni noma ukuncoma ubuchwepheshe besithando somkhathi ngenqubo efanele yokuhamba kwesikhathi.

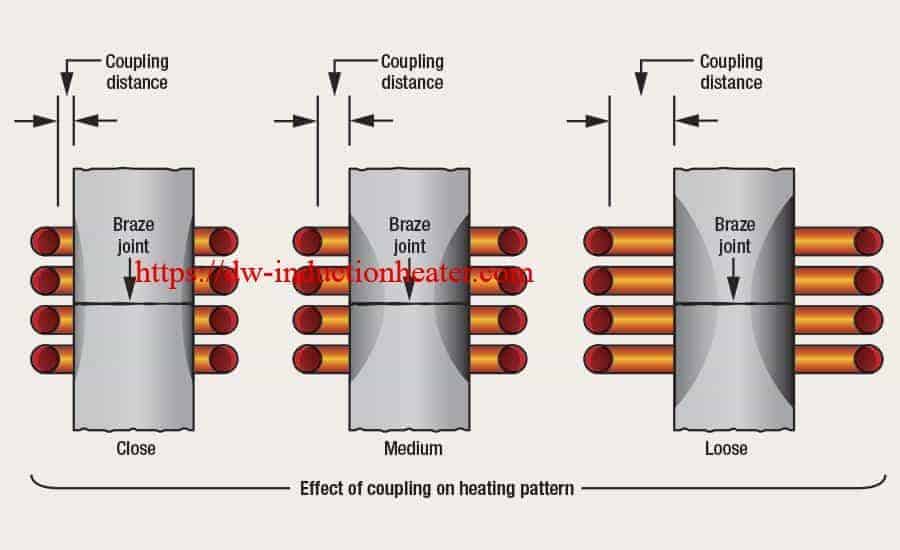

Ukususwa Kuthinta Amandla

Ukuhlukanisa phakathi kwezindawo zokuqhafaza okufanele zihlanganiswe kunquma inani le-braze alloy, isenzo se-capillary / ukungena kwe-alloy futhi ngemva kwalokho amandla okuhlanganyela okuphelile. Isimo esivumelana kahle kakhulu sezinhlelo zokusebenza ezivamile zesiliva zamasentimitha angu-0.002 (0.050 mm) kuya ku-0.005 mm (imvume ye-0.127 mm). I-aluminium ngokuvamile i-0.004 amasentimitha (0.102 mm) kuya ku-0.006 amasentimitha (0.153 mm). Izimvume ezinkulu kunamasentimitha angu-0.015 (0.380 mm) ngokuvamile azikho isenzo se-capillary esanele sebhande eliphumelelayo.

Ukubhincisa ngethusi (ngenhla kwe-1650 ° F / 900 ° C) kudinga ukubekezelelana okuhlangene kugcinwe okuncane kakhulu futhi kwezinye izimo ucindezeleke kahle emazingeni okushisa amancane ukuze kuqinisekiswe ukubekezelelana okungenani okuncane ngesikhathi sokushisa kwesibhakabhaka.

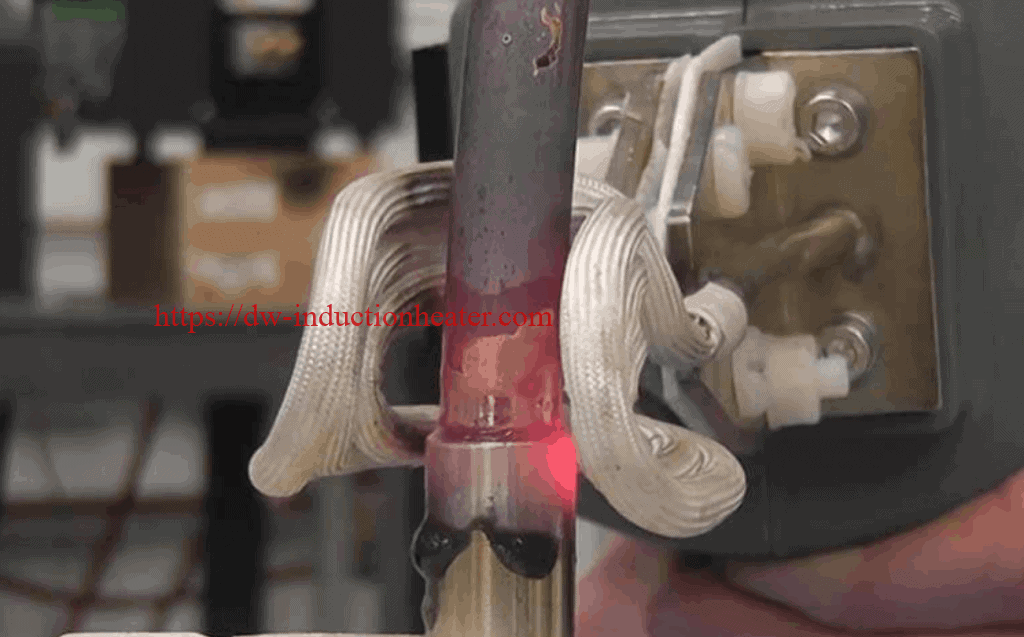

Ukufudumeza kokwethulwa kufakazelwe njengosizo oluhle kwinqubo yokujoyina ngezizathu eziningi. Isihloko esisheshayo nokulawulwa okuqondile kokushisa kunikeza ukuthi kungenzeka ukufudumala okwenziwe okwenziwa ngaphakathi kwezingxenye zamandla aphezulu ngaphandle kokushintsha kakhulu izakhiwo ezibonakalayo. Iphinde ivumele ukugqokwa kwezinto ezinzima ezifana ne-aluminium nokulandelana, ukubamba okungamakhemikhali amaningi nokwenza i-soldering yamajoyina asondele kakhulu.

Ukufudumeza kwendwangu ekufakweni kwezinsimbi nasekusebenziseni ugesi kufaka ukuzivumelanisa nezindlela zokukhiqiza kalula, kuvunyelwe ukuhlelwa kwamasu wemishini kulayini womhlangano, futhi uma kunesidingo, ukufudumeza ngokulawulwa okukude. Imvamisa, ukufakwa kokufakwa ngaphakathi kanye nokufakwa kwe-soldering kuvumela ukuncishiswa kwenombolo edingekayo yokulungiswa kwengxenye, ngokushisa okuncane kokulungiswa okwandisa isikhathi sokuphila kanye nokugcina ukunemba ekuvumelaniseni kwezingxenye ezizovunyelwa. Njengoba opharetha abadingi ukuhola umthombo wokufudumeza ongenayo, zombili izandla zishiywe zikhululekile ukulungiselela imihlangano yokujoyina.

I-HLQ imishini yokusebenza yokubopha uletha ikhwalithi, ukuvumelana, ukusetjheja okulungisekayo, kanye nokusebenzisa amatjhuguluko okusheshayo kwezidingo ezahlukahlukene zokukhiqiza. Umugqa womkhiqizo we-Radyne lokungeniswa kanye nowokuthambisa kagesi unikeza izixazululo ezijwayelekile zokubumba:

I-HLQ imishini yokusebenza yokubopha uletha ikhwalithi, ukuvumelana, ukusetjheja okulungisekayo, kanye nokusebenzisa amatjhuguluko okusheshayo kwezidingo ezahlukahlukene zokukhiqiza. Umugqa womkhiqizo we-Radyne lokungeniswa kanye nowokuthambisa kagesi unikeza izixazululo ezijwayelekile zokubumba:

Aluminum

Copper

Brass

Insimbi engagqwali

I-Carbide

Futhi nokuningi…