Induction Aluminium Brazing ngeKhompyutha Isizwayo

Induction aluminium brazing kuya ngokuya kuvama kakhulu embonini. Isibonelo esijwayelekile ukubopha amapayipi ahlukahlukene emzimbeni wezimoto oshintsha ukushisa. I- ukufakwa kwe-coil yokushisa esetshenziselwa kabanzi lolu hlobo lwenqubo ayizungezi eyodwa, engabizwa ngesitayela se- "Horseshoe-hairpin". Kula makhoyili, amandla kazibuthe nokusakazwa kwamanje kwe-eddy okuvela ku-3-D ngokwemvelo. Kulezi zicelo, kunezinkinga ngekhwalithi ehlangene nokuvumelana kwemiphumela kusuka engxenyeni kuya kwengxenye. Ukuxazulula inkinga eyodwa enjalo kumenzi omkhulu wezimoto, uhlelo lokulingisa ikhompyutha lweFlux3D lusetshenziselwe ucwaningo lwenqubo nokwenza kahle. Ukwenza ngcono kufaka phakathi ukuguqula ikhoyili yokungeniswa kanye nokucushwa kwesilawuli se-magnetic flux. Amakhoyili amasha wokungeniswa, aqinisekiswe ngokusemthethweni elabhoratri, akhiqiza izingxenye ezinamalunga wekhwalithi ephezulu ezindaweni eziningi zokukhiqiza.

Imoto ngayinye idinga ukushintshana kokushisa okuhlukahlukene (ama-heater cores, evaporators, condensers, radiators, njll.) Ukupholisa amandla, umoya opholisa umoya, ukupholisa uwoyela, njll. Iningi labashintshi bokushisa imoto yomgibeli namuhla lenziwe ngama-alloys e-aluminium noma e-aluminium. Noma ngabe injini efanayo isetshenziselwa amamodeli wezimoto eziningana, ukuxhumeka kungahluka ngenxa yezakhiwo ezahlukahlukene ngaphansi kwe-hood. Ngalesi sizathu, kungumkhuba ojwayelekile wabakhiqizi bezingxenye ukwenza imizimba eminingana yokushintsha ukushisa bese benamathisela izixhumi ezahlukahlukene ekusebenzeni kwesibili.

Imizimba eshintsha ukushisa imvamisa iqukethe amaphiko e-aluminium, amashubhu kanye namaheda aboshwe ndawonye esithandweni somlilo. Ngemuva kokubopha, amasheya wokushisa enzelwe imodeli yemoto enikeziwe ngokufaka noma yimaphi amathangi enayiloni noma amapayipi e-aluminium ahluke kakhulu ngamabhulokhi wokuxhuma. La mapayipi anamathiselwe nge-MIG welding, ilangabi noma ukufakelwa isibambo. Esimweni sokubamba, kudingeka ukulawulwa okushisa okucacile kakhulu ngenxa yomehluko omncane emazingeni okushisa ancibilikayo ne-brazing ye-aluminium (20-50 C kuya nge-alloy, filler metal kanye nomoya), ukuqhutshwa okuphezulu kwe-aluminium okushisayo kanye nebanga elifushane kokunye amalunga aboshwe ngomsebenzi wangaphambilini.

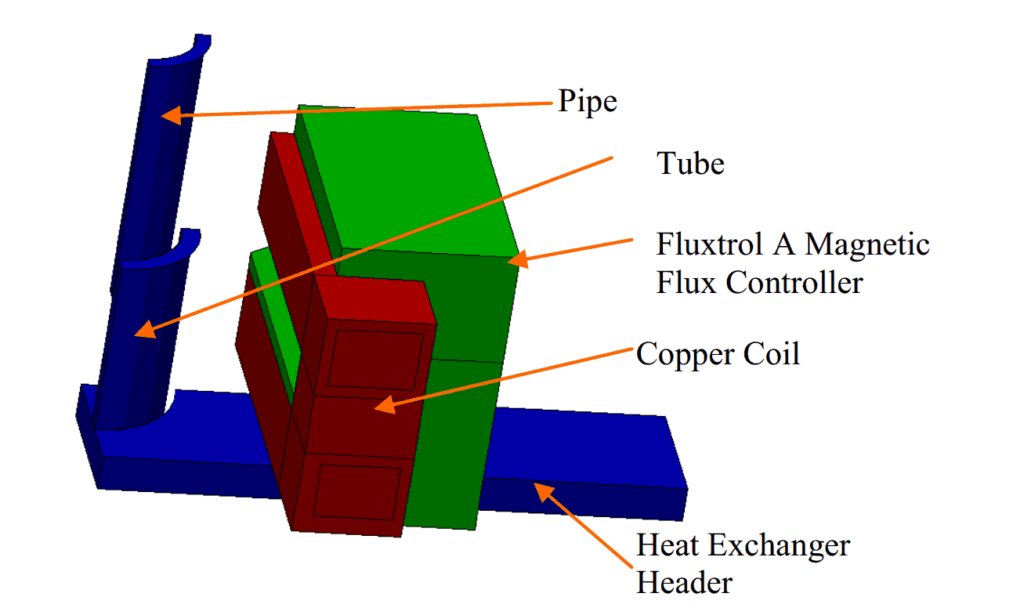

Ukushisa ukushisa kuyindlela ejwayelekile yokubopha amapayipi ahlukahlukene ukushisa izihloko zokushintsha. Umdwebo 1 isithombe se- Ukukhishwa kwesibalo ukusetha ukubopha ipayipi kushubhu kusihloko sokushintsha umzimba. Ngenxa yezidingo zokushisa okuqondile, ubuso bekhoyili yokungeniswa kumele bube seduze nejoyini elizobhediswa. Ngakho-ke ikhoyili ye-cylindrical elula ayinakusetshenziswa, ngoba ingxenye ayinakususwa ngemuva kokuthi ijoyini liboshwe.

Kunezitayela ezimbili zamakhoyili we-induction ezisetshenziselwa ukubopha la malungu: “i-clamshell” ne-“horseshoe-hairpin” inductors. Abangenisi be- "Clamshell" bayafana nabangenisi be-cylindrical, kepha bavulekele ukuvumela ukususwa kwengxenye. Abangenisi be- “Horseshoe-hairpin” babunjwe njengehhashi ukuze balayishe ingxenye futhi empeleni bangamakhoyili we-hairpin ezinhlangothini eziphambene zohlanganiso.

Ubuhle bokusebenzisa i- "Clamshell" inductor ukuthi ukufudumeza kufana kakhulu kusikwele futhi kulula ukubikezela. Ububi be-inductor ye- "Clamshell" ukuthi uhlelo lomshini oludingekayo luyinkimbinkimbi kakhulu futhi oxhumana nabo abaphezulu kakhulu manje abathembekile.

Abangenisi be- "Horseshoe-hairpin" bakhiqiza amaphethini wokushisa we-3-D anzima kakhulu kune- "Clamshells". Inzuzo yesitayela se-"Horseshoe-hairpin" isitayela ukuthi ingxenye yokuphatha yenziwe lula.

Ukulingiswa kwekhompyutha kuthuthukisa ukubopha

Umkhiqizi omkhulu wesishintshisi sokushisa ubenezinkinga zekhwalithi ngokubopha ijoyini eliboniswe ku-Fig. 1 esebenzisa i-inductor yesitayela se-horseshoe-hairpin Ukuhlanganiswa kwe-braze kwakulungele iningi lezingxenye, kepha ukufudumeza bekuzohluka ngokuphelele kwezinye izingxenye, okuholele ekujuleni kwenhlanganisela, amalunga abandayo nensimbi yokugcwalisa egudla udonga lwamapayipi ngenxa yokushisa kwendawo. Noma kuvivinywa umshini ngamunye wokushisa ukuthi kuvuza yini, ezinye izingxenye zisaputshuka kulejoyinti lisevisi. Isikhungo se-Induction Technology Inc. sinikezwe inkontileka yokuhlaziya nokuxazulula inkinga.

Ukunikezwa kwamandla okusetshenziselwa lo msebenzi kunemvamisa eguquguqukayo ka-10 kuye ku-25 kHz namandla alinganisiwe ka-60 kW. Ngenqubo yokubopha, opharetha ufaka indandatho yensimbi yokugcwalisa ekugcineni kwepayipi bese efaka ipayipi ngaphakathi kweshubhu. Isishintshisi sokushisa sifakwa kwi-rig ekhethekile futhi sihanjiswe ngaphakathi kwe-inductor yehhashi.

Yonke indawo yokubhonqa ifakwe kuqala. Imvamisa esetshenziselwa ukufudumeza ingxenye uqobo ingu-12 kuye ku-15 kHz, futhi isikhathi sokushisa cishe imizuzwana engama-20. Izinga lamandla lihlelwe ngokuncishiswa komugqa ekupheleni komjikelezo wokushisa. I-pyrometer ebonakalayo icisha amandla lapho izinga lokushisa ohlangothini olungemuva lokujoyina lifinyelela kunani elisethwe ngaphambili.

Kunezinto eziningi ezingadala ukungahambisani komkhiqizi obehlangabezana nakho, njengokuhlukahluka kwezingxenye ezihlangene (ubukhulu nobume) nokungazinzi nokuguquguquka (ngesikhathi) koxhumana ngogesi noshisayo phakathi kweshubhu, ipayipi, iringi yokugcwalisa, njll. azizinzile ngokwemvelo, futhi ukuhluka okuncane kwalezi zinto kungadala inqubo ehlukile yokuguquguquka. Isibonelo, iringi yensimbi evulekile yokuvula ingaphumula kancane ngaphansi kwamandla kagesi, futhi ukuphela kwamahhala kweringi kungabuyiselwa emuva ngamabutho e-capillary noma kuhlale kunganyakazisiwe. Izici zomsindo kunzima ukuzinciphisa noma ukuziqeda, futhi isixazululo senkinga besidinga ukukhulisa ukuqina kwenqubo ephelele. Ukulingiswa kwekhompyutha kuyithuluzi eliphumelelayo lokuhlaziya nokwandisa inqubo.

Ngesikhathi sokuhlolwa kwenqubo yokubopha, kwatholakala amandla amakhulu e-electrodynamic. Okwamanje amandla avuliwe, ikhoyili yesicathulo sehhashi ibona ngokucacile ukwanda ngenxa yokusetshenziswa okungazelelwe kwamandla kagesi. Ngakho-ke, i-inductor yenziwa yaqina ngomshini, kufaka phakathi ukufaka ipuleti elengeziwe le-fiberglass (G10) elixhuma izimpande zamakhoyili amabili we-hairpin. Okunye ukukhonjiswa kwamandla we-electrodynamic okwakukhona ukushintshwa kwensimbi encibilikisiwe isuka ezindaweni ezisondele ekujikeni kwethusi lapho amandla kazibuthe enamandla khona. Enkambisweni ejwayelekile, insimbi yokugcwalisa isabalalisa ngokufanayo ukuzungeza ilunga ngenxa yamandla we-capillary namandla adonsela phansi ngokungafani nenqubo engajwayelekile lapho insimbi yokugcwalisa ingaphelelwa yilungu noma inyukele phezulu endaweni yepayipi.

Ngoba induction aluminium brazing inqubo eyinkimbinkimbi kakhulu, akunakwenzeka ukulindela ukufaniswa okunembile kwalo lonke uchungechunge lwezinto ezihlangene (i-electromagnetic, i-thermal, i-mechanical, i-hydrodynamic ne-metallurgical). Inqubo ebaluleke kakhulu futhi elawulwayo ukukhiqizwa kwemithombo yokushisa kagesi, eyahlaziywa kusetshenziswa uhlelo lweFlux 3D. Ngenxa yesimo esiyinkimbinkimbi senqubo yokubamba induction, inhlanganisela yokulingiswa kwamakhompiyutha nokuhlolwa kwasetshenziselwa ukwakhiwa kwenqubo nokwenza kahle.