Ukuhlanganisa Insimbi neBrazing kanye neWelding

Kunezindlela eziningi ezitholakalayo zokujoyina izinsimbi, kufaka phakathi i-welding, i-brazing ne-soldering. Uyini umehluko phakathi kokushisela nokubopha? Uyini umehluko phakathi kokubopha nokufaka i-soldering? Ake sihlole umehluko kanye nezinzuzo zokuqhathanisa kanye nezicelo ezijwayelekile. Le ngxoxo izothuthukisa ukuqonda kwakho ukujoyina izinsimbi futhi ikusize ubone indlela efanelekile yohlelo lwakho lokusebenza.

INDLELA ESEBENZA NGAYO IBRAZING

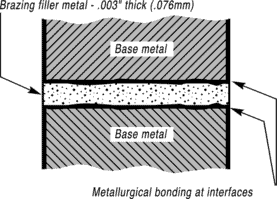

A ilunga elinethusi yenziwa ngendlela ehluke ngokuphelele ekuhlanganyeleni okushiselwe. Umehluko wokuqala omkhulu usezingeni lokushisa - i-brazing ayincibilikisi izinsimbi eziyisisekelo. Lokhu kusho ukuthi amazinga okushisa we-brazing ahlala ephansi kunamaphoyinti ancibilikayo ezinsimbi eziyisisekelo. Amazinga okushisa e-Brazing nawo aphansi kakhulu kunokushisa kwe-welding kwensimbi efanayo, kusetshenziswa amandla amancane.

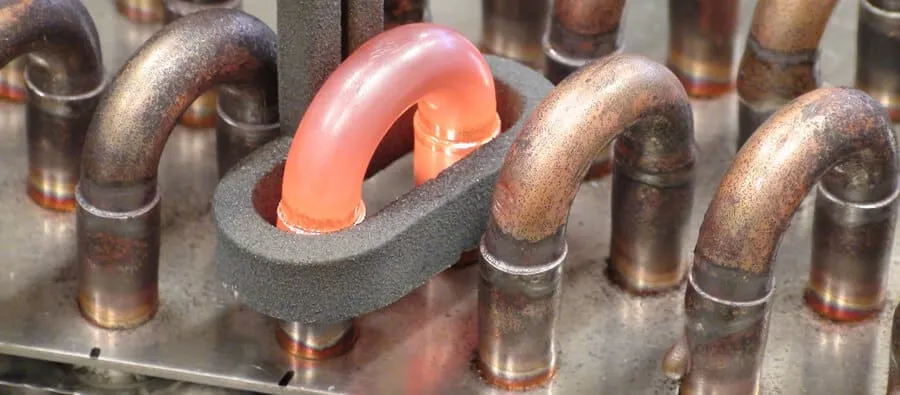

Uma ukubopha kungafaki izinsimbi eziyisisekelo, kubajoyina kanjani? Isebenza ngokwakha isibopho se-metallurgical phakathi kwensimbi yokugcwalisa kanye nezindawo zezinsimbi ezimbili ezihlanganiswayo. Umgomo lapho insimbi yokugcwalisa idwetshwa khona ngokuhlangana ukudala lobu bumbano isenzo se-capillary. Ekusebenzeni kwe-brazing, ufaka ukushisa kabanzi kuzinsimbi eziyisisekelo. Insimbi yokugcwalisa iyabe isihlangana nezingxenye ezifudumele. Iyancibilika khona manjalo ngokushisa ezinsimbini eziyisisekelo futhi kudonswe ngesenzo se-capillary ngokuphelele ngokuhlangana. Yile ndlela okwenziwa ngayo ilunga lethusi.

Izicelo zeBrazing zifaka i-elektroniki / ugesi, i-aerospace, yezimoto, i-HVAC / R, ukwakhiwa nokuningi. Izibonelo zisukela ezinhlelweni zokupholisa umoya zezimoto kuye emaceleni ama-jet turbine abucayi kakhulu kuya ezingxenyeni ze-satellite kuya kubucwebe obuhle. I-Brazing inikeza inzuzo enkulu ezinhlelweni ezidinga ukuhlanganiswa kwezinsimbi ezingafani, kufaka phakathi ithusi nensimbi kanye nezinto ezingezona izinsimbi ezifana ne-tungsten carbide, i-alumina, i-graphite nedayimane.

Izinzuzo Zokuqhathanisa. Okokuqala, ilunga elinethusi liyinhlangano eqinile. Ilunga elenziwe kahle elethusi (njengejoyinti elibushelwe) ezimweni eziningi lizoqina noma liqine kunezinsimbi ezihlanganiswayo. Okwesibili, ilunga lenziwa emazingeni okushisa aphansi kakhulu, kusuka cishe ku-1150 ° F kuye ku-1600 ° F (620 ° C kuye ku-870 ° C).

Okubaluleke kakhulu, izinsimbi eziyisisekelo azikaze zincibilike. Njengoba izinsimbi eziyisisekelo zingancibiliki, ngokuvamile zingagcina iningi lezakhiwo zazo zomzimba. Lokhu kuqina kwensimbi kuyisici sawo wonke amalunga abhedu, kufaka phakathi omabili amalunga amancanyana nacijile. Futhi, ukushisa okuphansi kunciphisa ubungozi bokuhlanekezelwa kwensimbi noma kokugoqana. Cabanga futhi, ukuthi amazinga okushisa aphansi adinga ukushisa okuncane - into ebalulekile yokonga izindleko.

Enye inzuzo ebalulekile yokubamba ubucwebe kulula ukujoyina izinsimbi ezingafani usebenzisa ama-alloys we-flux-cored / coated alloys. Uma kungadingeki uncibilikise izinsimbi eziyisisekelo ukuze uzijoyine, akunandaba ukuthi zinamaphuzu ancibilika ahluke kakhulu. Ungakwazi ukubopha insimbi yethusi kalula njengensimbi kuya ensimbi. Ukushisela yindaba ehlukile ngoba kufanele uncibilikise izinsimbi eziyisisekelo ukuze uzihlanganise. Lokhu kusho ukuthi uma uzama ukuhlanganisa ubhedu (iphuzu lokuncibilika 1981 ° F / 1083 ° C) kuya ensimbi (iphuzu lokuncibilika 2500 ° F / 1370 ° C), kufanele usebenzise amasu we-welding ayinkimbinkimbi futhi abizayo. Ukukhululeka okuphelele kokujoyina izinsimbi ezingafani ngezinqubo ezivamile zokubopha kusho ukuthi ungakhetha noma yiziphi izinsimbi ezifaneleke kangcono ukusebenza kwenhlangano, wazi ukuthi ngeke ube nankinga yokuzijoyina noma ngabe ziyahlukahluka kangakanani emazingeni okushisa ancibilikayo.

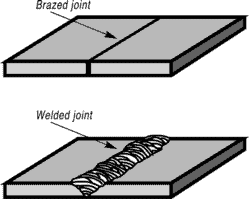

Futhi, a ilunga elinethusi ine ukubukeka bushelelezi, evumayo. Kunokuqhathanisa ubusuku nemini phakathi kwentambo encane, ecocekile yelungu elinethusi kanye nobuhlalu obujiyile, obungajwayelekile bejoyinti elishiselwe. Lesi sici sibaluleke kakhulu kumalunga emikhiqizo yabathengi, lapho ukubukeka kubaluleke khona. Ilunga elinethusi cishe njalo lingasetshenziswa “njengoba linjalo,” ngaphandle kokuqedela imisebenzi edingekayo - enye imali yokonga.

I-Brazing inikeza enye inzuzo ebalulekile ngaphezu kokushisela ukuthi opharetha bavame ukuthola amakhono okubamba ngokushesha kunamakhono wokushisela. Isizathu silele ngomehluko wemvelo phakathi kwalezi zinqubo ezimbili. Ukuhlangana okushisayo okuqondile kufanele kulandelwe ngokuvumelanisa okunembile kokufakwa kokushisa nokubekwa kwensimbi yokugcwalisa. Ilunga elinethusi, ngakolunye uhlangothi, livame “ukuzenza” ngokusebenzisa isenzo se-capillary. Eqinisweni, ingxenye enkulu yekhono elibandakanyeka ekubhuleni ibangelwa ukuklama nobunjiniyela bejoyini. Isivinini sokuqhathanisa sokuqeqeshwa kwabaqhubi abanamakhono kakhulu siyinto ebalulekile yezindleko.

Ekugcineni, ukubopha insimbi kulula ukuzisebenzisa. Izici zenqubo ye-brazing - ukufakwa kokushisa okubanzi nokusebenziseka kalula kokufakwa kwensimbi yokugcwalisa - kusiza ukuqeda amandla wezinkinga. Kunezindlela eziningi zokushisa ijoyini ngokuzenzakalela, izinhlobo eziningi zensimbi yokugcwalisa ibhrasi nezindlela eziningi zokuzifaka ukuze umsebenzi wokubamba uzenzele kalula cishe kunoma yiliphi izinga lokukhiqiza.

INDLELA OKUSEBENZA NGAYO I-WELING

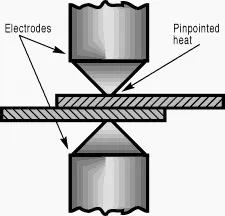

Ukushisela kujoyina izinsimbi ngokuzincibilikisa nokuzihlanganisa ndawonye, imvamisa ngokufakwa kwensimbi yokugcwalisa insimbi. Amalunga akhiqizwayo aqinile - imvamisa aqina njengokuhlangana kwezinsimbi, noma abe namandla ngokwengeziwe. Ukuxuba izinsimbi, ufaka ukushisa okugxile ngqo endaweni ehlanganisiwe. Lokhu kushisa kufanele kube nokushisa okuphezulu ukuze kuncibilike izinsimbi (izinsimbi ziyahlanganiswa) nezinsimbi zokugcwalisa. Ngakho-ke, amazinga okushisa we-welding aqala lapho kuncibilika khona izinsimbi eziyisisekelo.

Ukushisela insimbi kuvamise ukujoyina imihlangano emikhulu lapho zombili izingxenye zensimbi ziwugqinsi (0.5 ”/12.7mm) futhi zihlanganiswe endaweni eyodwa. Njengoba ubuhlalu bejoyini eline-welding bungajwayelekile, ayisetshenziswa kakhulu emikhiqizweni edinga amalunga ezimonyo. Izicelo zifaka ezokuthutha, ezokwakha, ezokukhiqiza nezokulungisa izitolo. Izibonelo yimihlangano yamarobhothi kanye nokwenziwa kwemikhumbi yengcindezi, amabhuloho, izakhiwo zokwakha, izindiza, abaqeqeshi bezitimela namathrekhi, amapayipi nokunye.

Izinzuzo Zokuqhathanisa. Ngoba ukushisa kwe-welding kukhulu, kuvame ukwenziwa kube okwendawo futhi kukhonjwe; akunangqondo ukuyisebenzisa ngokufanayo endaweni ebanzi. Lesi sici esikhonjisiwe sinezinzuzo zaso. Isibonelo, uma ufuna ukujoyina imicu emibili yensimbi ngasikhathi sinye, indlela kagesi yokuvikela ukumelana nensimbi iyasebenza. Le yindlela esheshayo, eyonga imali yokwenza amalunga aqinile, naphakade unamakhulu nezinkulungwane.

Uma ukujoyina kungumugqa kunokuba kuchazwe, noma kunjalo, kuvela izinkinga. Ukushisa kwasendaweni kwe-welding kungaba yinto embi. Isibonelo, uma ufuna ukukhipha izinsimbi ezimbili zensimbi, uqala ngokubhinca imiphetho yezingcezu zensimbi ukuze kuvunyelwe indawo yensimbi yokugcwalisa insimbi. Ngemuva kwalokho u-weld, uqala ukufudumeza umkhawulo owodwa wendawo ehlanganisiwe uye ekuncibilikiseni izinga lokushisa, bese uhambisa kancane ukushisa kulayini ohlanganisiwe, ufake insimbi yokugcwalisa ekuvumelaniseni nokushisa. Lokhu kuyinto ejwayelekile, evamile yokusebenza kwe-welding. Lenziwe kahle, lelijoyinti elihlanganisiwe okungenani liqinile njengoba izinsimbi zihlanganisiwe.

Kodwa-ke, kukhona ukungalungi kule ndlela yokuhlanganisa-ukuhlanganisa izinsimbi. Amalunga enziwa emazingeni okushisa aphezulu - aphezulu ngokwanele ukuba ancibilikise izinsimbi zombili zensimbi kanye nensimbi yokugcwalisa. Lezi zinga lokushisa eliphakeme zingadala izinkinga, kufaka phakathi ukuphazamiseka okungenzeka nokugoqa izinsimbi eziyisisekelo noma izingcindezi ezungeze indawo ye-weld. Lezi zingozi ziyingcosana lapho izinsimbi ezihlanganiswayo ziwugqinsi, kepha zingaba nezinkinga lapho izinsimbi eziyisisekelo ziyizigaba ezincane. Futhi, amazinga okushisa aphezulu ayabiza, ngoba ukushisa kungamandla futhi amandla abiza imali. Lapho udinga ukushisa okwengeziwe ukwenza ilunga, kuzobiza kakhulu ukuhlanganisa ukukhiqiza.

Manje, cabanga ngenqubo yokuzishisela ezenzakalelayo. Kwenzekani lapho ungajoyini hhayi umhlangano owodwa, kodwa amakhulu noma izinkulungwane zemihlangano? Ukushisela, ngokwemvelo yayo, kuletha izinkinga ku-automation. Ukuhlanganiswa kwe-weld-weld okwenziwe endaweni eyodwa kulula ukuyisebenzisa. Kodwa-ke, uma iphuzu liba umugqa - ukuhlangana okuqondile - futhi, umugqa kufanele ulandelwe. Kungenzeka ukwenza lo msebenzi wokuthungatha, ukuhambisa umugqa ohlangene, ngokwesibonelo, kudlule isiteshi sokushisa nokuphakela ucingo lokugcwalisa ngokuzenzakalela kusuka kuma-spools amakhulu. Lokhu ukusetha okuyinkimbinkimbi futhi okunamandla, noma kunjalo, kuvunyelwe kuphela uma unemikhakha emikhulu yokukhiqiza yezingxenye ezifanayo.

Khumbula ukuthi izindlela zokushisela ziyaqhubeka zithuthuka. Ungawelda ngesisekelo sokukhiqiza nge-electron beam, ukukhishwa kwe-capacitor, ukungqubuzana nezinye izindlela. Lezi zinqubo eziyinkimbinkimbi ngokuvamile zibiza imishini ekhethekile nebizayo kanye nama-setups ayinkimbinkimbi, adla isikhathi. Cabanga ukuthi ngabe ziyasebenziseka yini ekukhiqizeni okufushane, izinguquko ekucushweni komhlangano noma izidingo ezijwayelekile zensimbi zansuku zonke zokujoyina.

Ukukhetha Inqubo Yokujoyina Insimbi Elungile

Uma udinga amalunga ahlala unomphela futhi aqinile, cishe uzonciphisa izinsimbi zakho ngokujoyina ukucubungula ngokuqhathanisa ukugqolozela. Ukushisela nokubopha bobabili basebenzisa ukushisa nokugcwalisa izinsimbi.  Zombili zingenziwa ngesisekelo sokukhiqiza. Noma kunjalo, ukufana kugcina lapho. Zisebenza ngokuhlukile, ngakho-ke khumbula lokhu kucatshangelwa kwe-brazing vs welding:

Zombili zingenziwa ngesisekelo sokukhiqiza. Noma kunjalo, ukufana kugcina lapho. Zisebenza ngokuhlukile, ngakho-ke khumbula lokhu kucatshangelwa kwe-brazing vs welding:

Usayizi womhlangano

Ubukhulu bezingxenye zensimbi eyisisekelo

Spot noma line line izidingo

Izinsimbi ziyahlanganiswa

Inani lokugcina lomhlangano liyadingeka

Ezinye izinketho? Amalunga aboshelwe ngomshini (afakwe imicu, abekiwe noma ahlanganisiwe) imvamisa awaqhathanisi namalunga aboshwe ngamandla, ukumelana nokwethuka nokudlidliza, noma ukuqina kokuvuza. Ukunamathisela ukunamathisela kanye nokunamathisela ngomunwe kuzohlinzeka ngamabhondi waphakade, kepha ngokujwayelekile, futhi akunakunikeza amandla esihlanganisi esinebrazi - esilingana noma esikhulu kunaleso sensimbi uqobo. Futhi, njengomthetho, abakwazi ukukhiqiza amalunga ezinikeza ukumelana namazinga okushisa angaphezu kuka-200 ° F (93 ° C). Uma udinga amalunga wensimbi kuya ensimbi unomphela, anamandla, ukubopha kungumbangi oqinile.