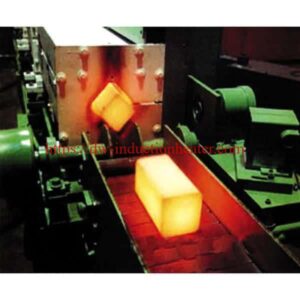

I-Induction Aluminium Billet Rod Heating Furnace

Incazelo

I-Induction Aluminium Billet Rod Heating Furnace, I-Induction Aluminium Billets Heater

I-induction aluminium billets isithando somlilo iklanywe ngokukhethekile futhi yenzelwe amabhilidi/izinduku ze-aluminium kanye nokwenza okushisayo. Isetshenziselwa ukushisisa amabhilidi/izinduku ze-aluminium ngaphambi kokufojwa kanye nenqubo yokukhishwa kwezinduku ze-aluminium ngemva kokushisisa.

1. Ubunzima ekwakhiweni kwamabhilidi e-aluminium/izinduku zokushisisa:

1). Amabhilidi/izinduku ze-Aluminium izinto ezingezona kazibuthe. Ekwakhiweni kokushisa kokungeniswa kwezinduku ze-aluminium, ikakhulukazi ukwakheka kwamakhoyili e-aluminium inductor, izindlela ezikhethekile zokuklama kufanele zamukelwe ukwenza izinduku ze-aluminium zikhiqize imisinga emikhulu ngesikhathi senqubo yokushisa, futhi ukugeleza kwemisinga emikhulu Induku ye-aluminium ngokwayo ikhiqiza. ukushisa ukuze ukushisa kwenduku ye-aluminium kuhlangabezane nezidingo zenqubo yokushisa.

2). Ngenxa yezici ze-aluminium, i-aluminium billet/induku ichitha ukushisa ngokushesha okukhulu. Ngakho-ke, isithando sokushisa induku ye-aluminium siyadingeka ukuthatha izinyathelo ezithile zokunciphisa ukupholisa kwenduku ye-aluminium. Lokhu kudinga okokusebenza kokushisisa kwe-aluminium rod ukuthi kufakwe i-aluminium rod reverse thrust device, ukuze kuqinisekiswe ukuthi ukuphela kwenduku ye-aluminium Izinga lokushisa lekhanda lihlangabezana nezidingo zenqubo yokushisisa.

2. Imingcele yokuklama ye i-aluminium billet/induku yokubumba isithando somlilo:

1). Isistimu yokuphakela amandla yentonga ye-aluminium yokushisisa: 160~1000KW/0.2~10KHZ.

2). Imishini yokushisisa induku ye-Aluminium Izinto zokushisa: ingxubevange ye-aluminium, i-aluminium billet nenduku

3). Ukusetshenziswa okuyinhloko kwemishini yokushisa induku ye-aluminium: esetshenziselwa ukukhishwa okushisayo nokwakhiwa kwezinduku ze-aluminium nama-alloys e-aluminium.

4). Uhlelo lokuphakelayo lwemishini yokushisisa induku ye-aluminium: isilinda noma isilinda se-hydraulic siphusha impahla ngezikhathi ezithile

5). Isistimu yokukhipha isithando somlilo se-aluminium induction rod: uhlelo lokudlulisa i-roller.

6). Ukusetshenziswa kwamandla kwemishini yokushisa induku ye-aluminium: ukushisisa ithani ngalinye lezinto ze-aluminium ku-450℃~560℃, ukusetshenziswa kwamandla kungu-190~320℃.

7). Imishini yokushisa induku ye-aluminium ihlinzeka nge-remote operation console enesikrini sokuthinta noma isistimu yekhompyutha yezimboni ngokuya ngezidingo zomsebenzisi.

8). Isixhumi esibonakalayo somshini womuntu olungiselelwe ngokukhethekile okokusebenza kokushisisa kwenduku ye-aluminium, imiyalelo yokusebenza komuntu kakhulu.

9). I-All-digital, amapharamitha alungisekayo ajule kakhulu we-aluminium billet/isithando sokushisa induku

10). Ukuguqulwa kwamandla kwesithando sokushisa kwenduku ye-aluminium: ukushisa kufika ku-550°C, ukusetshenziswa kwamandla 240-280KHH/T

3. I-Aluminium billet/induku Yokungeniswa Ukushisa Ikhoyili/Inductor

Inqubo yokukhiqiza i-inductor yenduku yokushisisa ye-Aluminium: Isilinganiso sobubanzi bangaphakathi bekhoyili ye-aluminium yokushisisa intonga yokushisa kuya kububanzi obungaphandle be-billet ingaphakathi kwebanga elinengqondo, futhi iklanywe ngokuvumelana nemingcele yenqubo enikezwa umsebenzisi. Ikhoyili ye-inductor yenziwe ngepayipi elikhulu le-T2 elingunxande le-cross-section, elifakwe emanzini, lilonda, lifakwe emanzini anosawoti, lihlolwe nge-hydrostatically, libhakwe, njll. Ngemva kokufakwa okuningi, ukomisa, ukuhlanganisa, ukuhlanganisa kanye nezinye izinqubo eziyinhloko ukuqedela, bese zilungiswa. ku-A Sekukonke, inzwa yonke yakheka ibe yi-cuboid ngemva kokwakhiwa, futhi ukumelana kwayo nokudlidliza nobuqotho kuhle. Kunamapuleti ethusi omlomo wesithando somlilo opholiswe ngamanzi kuzo zombili iziphetho ze-inductor ukuvikela ikhoyili yesithando sokungenisa esishisiswe yinduku ye-aluminium, futhi ngesikhathi esifanayo, ingavimbela ngokuphumelelayo imisebe ye-electromagnetic ukuthi ingalimazi opharetha.

4. Igama lesithando sokushisa induku ye-aluminium:

Imishini yokushisisa induku ye-aluminium ngokuyinhloko iba iziko likagesi eliphakathi nendawo eliphakathi nendawo njenge-aluminium induku ephakathi nendawo yokufudumeza isithando somlilo, isithando somlilo sokungeniswa kwe-aluminium, isithando somlilo se-aluminium induction, i-aluminium ingot induction yokushisa isithando somlilo, njll. ukugingqa nokugunda kwezinto zensimbi zokushisa.

5. Ukwakheka kwesithando somlilo se-aluminium rod:

Ukwakhiwa kwemishini yokushisa induku ye-aluminium: 1. Ukunikezwa kwamandla okushisa okungeniswayo; 2. Ikhabhinethi yokushisa isithando somlilo (kuhlanganise namapayipi ensimbi engagqwali namakhabhinethi e-capacitor); 3. Ukushisa kwesithando sokufakelwa umzimba; 4. Ukuphakela okuzenzakalelayo kanye nohlelo lokuphusha isikhathi; 5. Ukusebenza kwe-PLC Ikhabhinethi yokulawula; 6. Idivayisi yokukhipha ngokushesha; 7. Isilinganiso sokushisa kwe-infrared kanye nesistimu yokulawula ukushisa okuzenzakalelayo

6. izici ze i-aluminium billet/induku yokushisa isithando somlilo

Izici eziyinhloko ze-aluminium rod aluminium billet/isithando sokushisa induku:

1). Isithando somlilo se-aluminium sokushisa sinesivinini sokushisa okusheshayo kanye nezinga eliphansi lokulahlekelwa okuvuthayo; ukukhiqizwa okuqhubekayo kuzinzile, futhi kulula futhi kulula ukuyinakekela.

2). Indlela ekhethekile yokuklama ikhoyili ye-inductor/induction yesithando sokushisa induku ye-aluminium iqinisekisa umehluko wezinga lokushisa phakathi kwendawo entsha futhi ingasetshenziselwa ukushisisa izinti ze-aluminium ezicaciswe ezihlukahlukene.

3). Isithando sokushisa senduku ye-aluminium sithatha ithemometha ye-infrared engenisiwe ukuze kuqinisekiswe ukunemba kokulinganisa nokuphindaphinda. Indawo yokushisisa nendawo yokulondoloza ukushisa inokushesha ukufudumala kwamabhilidi/izinduku ze-aluminium.

4). Umbhoshongo omusha wokupholisa wensimbi engagqwali ovaliwe uqeda inkinga yokumba ichibi.

5). Indlela yokudla okuzenzakalelayo ye-aluminium billet/induku yokushisisa isithando somlilo ingaphakela ngokuqondile ingot ye-aluminium ingenalutho kusukela phansi.

6). Ukukhiqizwa okuqhubekayo okuzinzile, ukusebenza kahle kokukhiqiza okuphezulu, ukugcinwa okulula nokulula, futhi kungasetshenziswa ekushiseni izinti ze-aluminium zokucaciswa okuhlukahlukene.

7). Ukusabalalisa izinga lokushisa lokushisa kwe-aluminium billet / isithando sokushisa somlilo: isithando somlilo se-aluminium sihlukaniswe endaweni yokushisa, indawo yokushisa kanye nendawo yokugcina ukushisa.