induction ukushisisa ipulasitiki granulator

Incazelo

Ukwethulwa Kafushane kokushisisa i-plastic granulator/i-plastic extrusion:

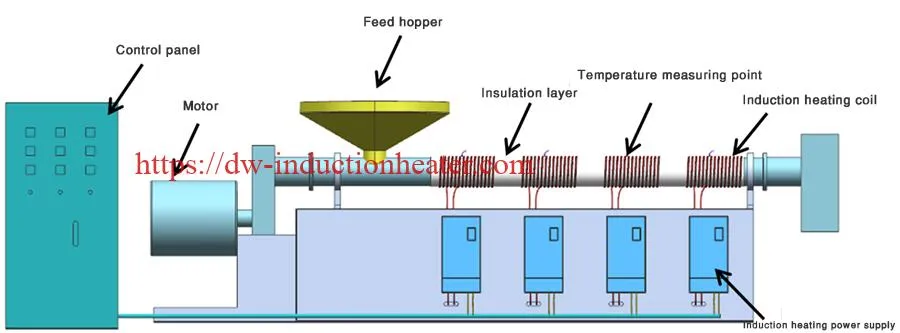

Ukushisa ukushisa imbudumbudu yepulasitiki/i-plastic extrusion wuhlobo olulodwa lwe-heater yokonga amandla. Inezinzuzo eziningi ezihlanganisa ukonga ugesi okubalulekile, ukushisisa ngokushesha, ukonga amandla aphezulu, ukunakekela okuphansi noma okuyiziro njll. Ingase futhi yehlise izinga lokushisa lendawo ngokuphehla ukushisa okuncane kakhulu. Ngenkathi ufaka isistimu ye-heater yokungeniswa, ngeke ifake noma yiziphi izinguquko ezinkulu ohlelweni lokulawula ugesi.

Ungashisisa kuphi i-plastic granulator/extrusion yepulasitiki?

Ungashisisa kuphi i-plastic granulator/extrusion yepulasitiki?

Ngokuyinhloko isetshenziselwa umjovo, i-extrusion; ukuthwebula ifilimu, ukudweba ngocingo, imishini ye-granulating kanye ne-recycling, njll. Isicelo somkhiqizo sihlanganisa ifilimu, ishidi, iphrofayili, impahla eluhlaza njll. Ingasetshenziselwa ukushisa umgqomo, i-flange, i-die head, i-screw nezinye izingxenye zemishini. Yinhle kakhulu ekongeni amandla nasekupholiseni indawo yokusebenza.

Ukushisa ukushisa kuyinqubo yokushisisa into eqhutshwa ngogesi (imvamisa eyinsimbi) ngokungeniswa kwe-electromagnetic, lapho ama-eddy currents akhiqizwa ngaphakathi kwensimbi futhi ukumelana kuholela ekushiseni kwe-Joule kwensimbi. Ikhoyili ye-induction ngokwayo ayishisi. Into ekhiqiza ukushisa yiyona nto eshisisayo.

Kungani futhi kanjani induction ukushisisa plastic granulator/plastic extrusion kungawonga amandla?

Njengamanje, iningi lemishini yepulasitiki isebenzisa indlela evamile yokushisa yokumelana, lapho intambo yokumelana ishiselwa khona bese idlulisela ukushisa emgqonyeni ngesembozo se-heater. ukushisa eduze nesembozo se-heater yangaphandle kulahleka emoyeni okubangela ukunyuka kwezinga lokushisa kwendawo.

I-heater yokungeniswa ubuchwepheshe lapho amandla kazibuthe efrikhwensi ephezulu abangela ukuthi ashiselwe i-bu electro-magnetic field(EMF) egudlanayo.Lapho umgqomo ushiselwa futhi nokushisa kuncane, kuba nokushisa okuphezulu kakhulu kanye nokulahlekelwa ukushisa okuncane indawo lapho ukonga amandla kungafinyelela ku-30-80%.Ngenxa yokuthi ikhoyili yokungeniswa ayikhiqizi ukushisa okuphezulu futhi futhi alukho intambo yokumelana ne-oxidized bese ibangela ukuthi i-heater iphele, i-heater yokungeniswa inesevisi ende. impilo kanye nesondlo esincane.

Yiziphi izinzuzo zokushisisa i-plastic granulator/i-plastic extrusion?

Yiziphi izinzuzo zokushisisa i-plastic granulator/i-plastic extrusion?

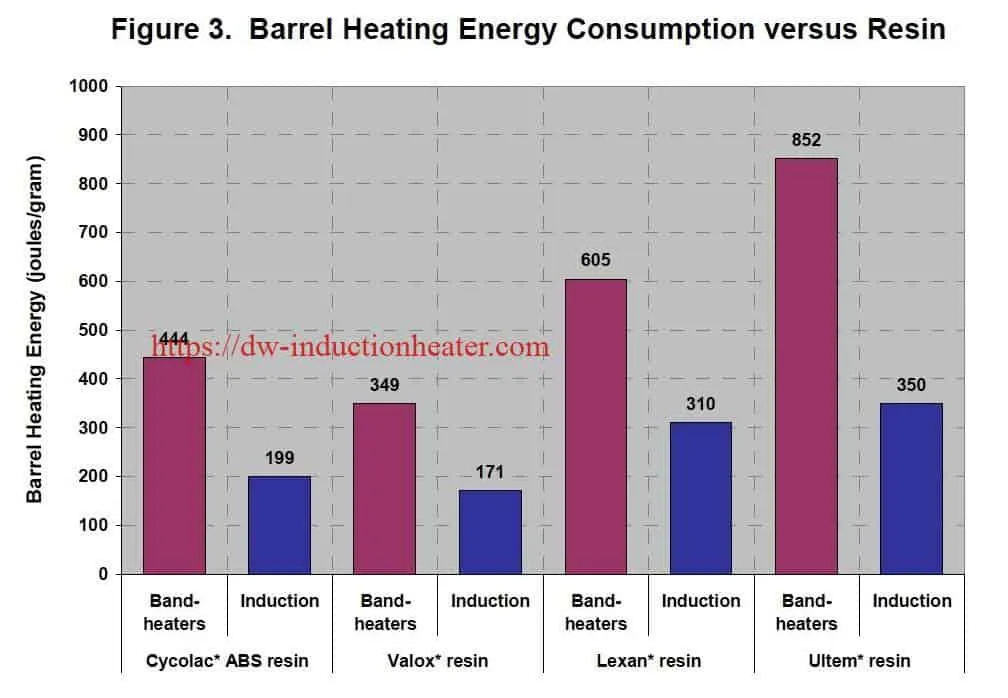

- Ukusebenza kahle kwamandla 30%-85%

Njengamanje, imishini yokucubungula ipulasitiki isebenzisa ikakhulukazi izakhi zokushisa ezingase zikhiqize inani elikhulu lokushisa elikhishwa endaweni ezungezile. Ukushisa kwe-induction kuyindlela ekahle yokuxazulula le nkinga. Izinga lokushisa elingaphezulu kwamakhoyili okushisa lokungeniswa liphakathi kuka-50ºC no-90ºC, ukulahlekelwa ukushisa kuncishiswa kakhulu, kuhlinzeka ukonga kwamandla okungama-30% -85%. Ngakho-ke umphumela wokonga amandla ubonakala kakhulu lapho isistimu yokushisisa yokungeniswa isetshenziswa kumishini yokushisa yamandla aphezulu.

Ukuphepha

Ukuphepha

Ukusebenzisa i-induction heat system kwenza ingaphezulu lomshini liphephe ukuthintwa, futhi lokho kusho ukuthi lingagwema ukulimala kokushiswa okuvame ukwenzeka emishinini yepulasitiki esebenzisa izinto zokushisa eziphikisanayo, ehlinzeka ngendawo yokusebenzela ephephile kubaqhubi.- Ukushisa okusheshayo, ukusebenza kahle kokushisa okuphezulu

Uma kuqhathaniswa nokushisisa ukumelana nokuguqulwa kwamandla okusebenza kahle kucishe kube ku-60%, ukushisisa kwe-induction kusebenza kahle ngaphezu kuka-98% ekuguquleni ugesi ube ukushisa. - Izinga lokushisa eliphansi lomsebenzi, induduzo yokusebenza ephezulu

Ngemuva kokusebenzisa uhlelo lokushisa lokungeniswa, izinga lokushisa layo yonke indawo yokusebenzela yokukhiqiza lehla ngama-degree angaphezu kwama-5. - Ukuphila kwesikhathi eside

Ngokuphambene nezinto zokushisa eziphikisanayo okufanele zisebenze isikhathi eside ekushiseni okuphezulu, ukushisa kwe-induction kusebenza eduze nezinga lokushisa elizungezile, ngakho-ke kwandisa impilo yesevisi ngendlela efanele. - Ukulawula izinga lokushisa okunembile, izinga eliphezulu lokufaneleka komkhiqizo

Ukushisa kwe-induction kunikeza inertia ephansi noma engekho eshisayo, ukuze ingeke ibangele ukushisa ngokweqile. Futhi izinga lokushisa lingahlala linani elimisiwe likamehluko we-0.5 degree.

Yikuphi ukuphakama kokushisisa kwepulasitiki/i-plastic extrusion uma kuqhathaniswa nezifudumezi zendabuko?

Yikuphi ukuphakama kokushisisa kwepulasitiki/i-plastic extrusion uma kuqhathaniswa nezifudumezi zendabuko?

| I-heater yokungeniswa | Izishisi zendabuko | |

| Indlela Yokushisa | Ukushisa okungeniswayo kuyinqubo yokushisisa into eqhutshwa ngogesi (imvamisa eyinsimbi) ngokungeniswa kwe-electromagnetic, lapho ama-eddy currents akhiqizwa ngaphakathi kwensimbi futhi ukumelana kuholela ekushiseni kwe-Joule kwensimbi. Ikhoyili ye-induction ngokwayo ayishisi. Into ekhiqiza ukushisa yiyona nto eshisisayo | Izintambo zokuthintwa ziyashisisa ngokuqondile futhi ukushisa kudluliselwa ngothintwayo. |

| ukushisa isikhathi | Ukushisisa okusheshayo, ukusebenza kahle okuphezulu | ukushisisa kancane, ukusebenza kahle okuphansi |

| Izinga lokonga amandla |

Yonga u-30-80% wezinga lamandla, yehlisa izinga lokushisa lokusebenza |

Ayikwazi ukonga amandla |

| Ukufakwa | Ifakeka | Ifakeka |

| Operation | Kulula ukusebenza | Kulula ukusebenza |

| Maintenance |

Ibhokisi lokulawula kulula ukulishintsha ngaphandle kokuvala umshini wakho |

Kulula ukushintsha kodwa kufanele uvale umshini wakho |

| Ukulawula izinga lokushisa | Inertia encane eshisayo kanye nokulawula izinga lokushisa okunembile ngenxa yokuthi i-heater ayizishisi ngokwayo. | I-inertia enkulu yokushisa, ukunemba okuphansi ekulawuleni izinga lokushisa |

| Ikhwalithi Yomkhiqizo | Ikhwalithi yomkhiqizo ephezulu ngenxa yokulawula izinga lokushisa okunembile | Ikhwalithi yomkhiqizo ephansi |

| Ukuphepha |

Umgodla wangaphandle uphephile ukuthi ungawuthinta, izinga lokushisa eliphansi elingaphezulu, akukho ukuvuza kukagesi. |

Izinga lokushisa emgodleni wangaphandle liphakeme kakhulu, kulula ukushiswa. Ukuvuza kukagesi ngaphansi kokusebenza okungalungile. |

| Impilo yesevisi ye-heater | 2-4years | iminyaka 1-2 |

| Impilo yesevisi ye-Barrel and Screw |

Impilo ende yokusetshenziswa komgqomo, isikulufu njll. ngenxa yemvamisa ephansi yokushintsha ama-heater. |

Impilo emfushane yokusebenzisa umgqomo, isikulufu njll. |

| Environment | Izinga lokushisa eliphansi lemvelo; Akukho msindo |

Izinga lokushisa lendawo ephakeme kakhulu nomsindo omkhulu |

I-Induction Heating Power Calculation

Endabeni yokwazi amandla okushisa esistimu yokushisa ekhona, ukukhetha amandla afanele ngokwesilinganiso somthwalo

- Izinga lokulayisha ≤ 60%, amandla asebenzayo angu-80% wamandla okuqala;

- Izinga lokulayisha phakathi kuka-60% -80%, khetha amandla okuqala;

- Izinga lokulayisha > 80%, amandla asebenzayo angu-120% wamandla okuqala;

Lapho amandla okushisa esistimu yokushisa ekhona akwaziwa

- Ngomshini wokubumba umjovo, umshini wefilimu ovutheliwe kanye nomshini wokukhipha amandla, amandla kufanele abalwe njenge-3W nge-cm2 ngayinye ngokusho kwendawo yangempela ye-cylinder (umgqomo);

- Ngomshini owomile wokusika i-pelletizing, amandla kufanele abalwe njenge-4W nge-cm2 ngayinye ngokusho kwendawo yangempela yesilinda (umgqomo);

- Ngomshini we-pelletizing osikiwe omanzi, amandla kufanele abalwe njengo-8W nge-cm2 ngayinye ngokusho kwendawo yangempela yesilinda (umgqomo);

Isibonelo: ububanzi besilinda 160mm, ubude 1000mm (okungukuthi 160mm=16cm, 1000mm=100cm)

Isibalo sendawo yesilinda: 16*3.14*100=5024cm²

Ibala njengo-3W nge-cm2 ngayinye: 5024*3=15072W, okungukuthi 15kW