I-Stainless Steel Reactor Heating Induction

Incazelo

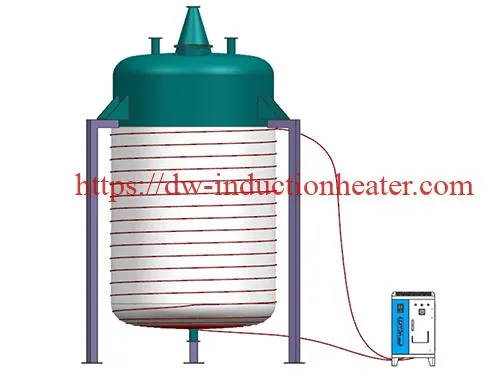

I-Induction Heating 304 #, 310 #, 316 # igedlela lokuphendula lensimbi engagqwali, isitsha esingenasici

Ama-reactors wamakhemikhali okungenisa ukushisa Ama-Reactors namaKettles, ama-Autoclaves, ama-Process Vessels, ama-Storage kanye nama-Settling Tanks, ama-Baths, ama-Vats namabhodwe ama-Still, Izitsha Zokucindezela, ama-Vapourisors nama-superheater, ama-Heat Exchange, ama-Rotary Drums, ama-Pipes, ama-Dual Fuel Heated Heels nemikhumbi yamakhemikhali yizona zinto ezihamba phambili kakhulu zokushisa indlela etholakalayo yokucubungula uketshezi.

Izindlela zokushisisa zendabuko zezinhlobo ezahlukahlukene zama-reactor ngokuyisisekelo zisebenzisa izintambo zokumelana, igesi, uwoyela wesibaseli, i-biofuel noma okunye ukushisisa okungaqondile. Cishe zonke izindlela zokushisisa zisebenzisa isimiso sokuhluka kwezinga lokushisa ukuze kuzuzwe ukudluliswa kokushisa. Ngakolunye uhlangothi, le nqubo yokushisa yendabuko Amandla okushisa azochithwa ngesikhathi sokudlulisa, futhi ngakolunye uhlangothi, ukusebenza kahle kokukhiqiza kwemishini kuzoncishiswa ngoba ubukhulu bomehluko wokushisa buzothinta isivinini sokushisa.

Izindlela zokushisisa zendabuko zezinhlobo ezahlukahlukene zama-reactor ngokuyisisekelo zisebenzisa izintambo zokumelana, igesi, uwoyela wesibaseli, i-biofuel noma okunye ukushisisa okungaqondile. Cishe zonke izindlela zokushisisa zisebenzisa isimiso sokuhluka kwezinga lokushisa ukuze kuzuzwe ukudluliswa kokushisa. Ngakolunye uhlangothi, le nqubo yokushisa yendabuko Amandla okushisa azochithwa ngesikhathi sokudlulisa, futhi ngakolunye uhlangothi, ukusebenza kahle kokukhiqiza kwemishini kuzoncishiswa ngoba ubukhulu bomehluko wokushisa buzothinta isivinini sokushisa.

The i-heater ye-electromagnetic isebenzisa igedlela lokusabela njengesiphathi, futhi ithatha indawo yokushisisa kokudlulisa okungokwesiko ngokushisisa idrayivu ye-electromagnetic, futhi idonsa ngokuqondile ukushisa emzimbeni wegedlela lokusabela, ukuze isivinini sokushisisa singathuthukiswa. Ngesikhathi esifanayo, ikhoyili ingahlelwa odongeni lwangaphandle o f igedlela lokusabela, futhi idivayisi yokushisa ngeke yonakaliswe ngenxa yokushisa okuphezulu ku-kettle yokusabela. Ngesikhathi esifanayo, akukho ukukhishwa okubangelwa inqubo yokushisa ngesikhathi sokushisa, okuxazulula inkinga yokusebenza kahle kokukhiqiza okuphansi kwemishini yokushisa yendabuko kanye nokugcinwa kwezinto zokushisa. Izinkinga ezivamile kanye nokungcoliswa kwemvelo okubangelwa ukushiswa.

f igedlela lokusabela, futhi idivayisi yokushisa ngeke yonakaliswe ngenxa yokushisa okuphezulu ku-kettle yokusabela. Ngesikhathi esifanayo, akukho ukukhishwa okubangelwa inqubo yokushisa ngesikhathi sokushisa, okuxazulula inkinga yokusebenza kahle kokukhiqiza okuphansi kwemishini yokushisa yendabuko kanye nokugcinwa kwezinto zokushisa. Izinkinga ezivamile kanye nokungcoliswa kwemvelo okubangelwa ukushiswa.

- Amandla asebenza kahle

Ukushisisa okungeniswayo kusebenza kahle ngaphezu kuka-98% ekuguquleni ugesi ekushiseni, okunikeza ukonga amandla okungama-30% nangaphezulu. - Kuphephile futhi kunokwethenjelwa

Ngokuhambisana nokulawula okuhlakaniphile, ukushisa kwe-induction kuqeda isidingo samalangabi avulekile kanye nezisetshenziswa zokushisa, kuqinisekisa ukusebenza okuphephile. - Eco-friendly

Ngaphandle kwesidingo somlilo ovulekile, ukushisisa kwe-induction akukhiqizi uthuli, iphunga, umsindo namagesi ayingozi, okuhambisana nezidingo zeNqubomgomo Kazwelonke Yokonga Amandla. - Ukulawulwa kwedijithali

Isistimu yokulawula idijithali iqinisekisa ukulawulwa kwezinga lokushisa okunembile, okuhlinzeka ngokusebenza okuhlakaniphile. - Isakhiwo esihlangene, ukugcinwa okulula

Sine umshini wokufudumeza lokungeniswa kusuka ku-1KW ~ 500KW. Izinga lokushisa lokushisa ngu-0~650 C. Singenza umshini wokushisa wokungenisa ofanelekayo we-reactor yohlobo oluhlukile.

Inzuzo yokufudumeza kokungeniswa kokushisa kabusha:

1. Isivinini sokushisa esisheshayo esinomphumela ophezulu wokushisa

2. Akukho ukuthintana ngokomzimba phakathi kwe-coil ye-induction nodonga lomkhumbi oshisayo

3. Ukuqalisa okusheshayo nokuvala; ayikho i-inertia eshisayo

4. Ukulahlekelwa ukushisa okuphansi

5.Ukulawula umkhiqizo kanye nokulawula izinga lokushisa lomkhumbi ngaphandle kokudubula ngaphezulu

6. Ukufakwa kwamandla okuphezulu, okulungele ukulawula okuzenzakalelayo noma kwe-micro-processor

7. Indawo enobungozi ephephile noma ukusebenza okujwayelekile kwezimboni kulayini wentambo

8. Ukungcola Ukushisa iyunifomu khulula at ukusebenza kahle eliphezulu

9. Izindleko zokugijima eziphansi

10. Ukushisa okuphansi noma okuphezulu

11. Simple futhi nezimo ukusebenza

12. Ukugcinwa okuncane

13. Ikhwalithi yomkhiqizo ehambisanayo

14. Isifudumezi sinemithwalo yemoto enesidingo sendawo ephansi

15. Iphephile futhi izinzile amahora angama-24 isebenza & Ngaphezulu kweminyaka eyi-10 yokuphila okusebenzayo

Imiklamo yokushisa ye-induction ayatholakala ukufanisa umkhumbi wensimbi namathangi amafomu amaningi namajamo aqala ngamasentimitha ambalwa kuya kumamitha amaningana ububanzi noma ubude. Insimbi emnene, egqoke insimbi emnene, insimbi engagqwali eqinile noma izitsha ezingekho zensimbi zingashiswa ngempumelelo. Ngokuvamile kunconywa ubuncane bodonga obungu-6 ~ 10mm.

The umshini we-induction weld preheating zihlanganisa:

1. amandla wokushisa wokungeniswa.

2.Ikhoyili yokushisa yokungeniswa.

3. Nweba ikhebula

4. K thayipha i-thermocouple njalonjalo.

Ukushisa kwe-induction kunikeza izinzuzo ezingatholakali kwezinye izinhlelo: ukusebenza kahle kokukhiqizwa kwezitshalo nezimo zokusebenza ezingcono ngaphandle kokukhipha okuphawulekayo kokushisa ezindaweni ezizungezile.

Izimboni ezijwayelekile ezisebenzisa ukufudumeza kwenqubo yokwenziwa:

• Ama-reactor namaketela.

• Ukunamathela nokunamathisela okukhethekile.

• Amakhemikhali, igesi kanye namafutha.

• Ukulungiswa kokudla.

• Ukuqedwa kweMetallurgical nensimbi nokunye.

I-HLQ Induction Heating Chemical Reactor/ Umkhiqizi Wesistimu Yezitsha

Sinesipiliyoni seminyaka engaphezu kwengu-20 ku Ukushisa ukufakelwa futhi sithuthukise, sakha, sakha, safaka futhi safaka izinhlelo ze-Vessel ne-Pipe Heating emazweni amaningi emhlabeni jikelele.Ngenxa yokuthi uhlelo lokushisa luyinto elula ngokwemvelo futhi enokwethenjelwa kakhulu, inketho yokufudumeza ngokungeniswa kufanele ibhekwe njengokukhetha okukhethiwe. Ukushisa kwe-induction kufaka zonke izinto ezilula zikagesi ezithathwe ngqo enqubeni futhi zaguqulwa zashisa ngqo lapho kudingeka khona. Ingasetshenziswa ngempumelelo kunoma yisiphi isitsha noma uhlelo lwamapayipi oludinga umthombo wokushisa.

Ukungeniswa kunikeza izinzuzo eziningi ezingatholakali ngezinye izindlela futhi kunikeza ukusebenza okuthuthukile kokukhiqizwa kwezitshalo nezimo zokusebenza ezingcono ngoba akukho ukukhishwa okuphawulekayo kokushisa ezindaweni ezizungezile. Lolu hlelo lufanele ikakhulukazi izinqubo zokuphendula eziseduze njengokukhiqizwa kwezinhlaka zokwenziwa endaweni eyiNgozi.

Njengoba ngamunye induction Ukushisa isitsha is bespoke kumakhasimende ngamunye izidingo ezithile kanye nezidingo, sinikeza osayizi abahlukahlukene ngamazinga ahlukene okushisa. Onjiniyela bethu babe neminyaka eminingi yokuhlangenwe nakho okwenziwe ngokwezifiso ukushisa ukushisa izinhlelo ezinhlobonhlobo zezicelo ezinhlobonhlobo zezimboni. Ama-heater aklanyelwe ukuhambisana nezidingo eziqondile zenqubo futhi akhelwe ukufaka ngokushesha emkhunjini emisebenzini yethu noma esizeni.

IZINZUZO EZIYIQOQO

• Akukho ukuxhumana okungokomzimba phakathi kwekhoyili yokungeniswa nodonga lomkhumbi oshisayo.

• Ukuqalisa okusheshayo nokuvala. Ayikho i-inertia eshisayo.

• Ukulahlekelwa ukushisa okuphansi

• Ukulawulwa kokushisa komkhiqizo kanye nomkhumbi odongeni ngaphandle kokudubula ngaphezulu.

• Ukufakwa kwamandla amaningi. Ilungele ukulawula okuzenzakalelayo noma kwe-micro-processor

• Indawo enobungozi ephephile noma ukusebenza okujwayelekile kwezimboni kumugqa wentambo.

• Ukushisa kokungcoliswa kwamahhala kokungcoliswa kokusebenza kahle.

• Izindleko zokugijima eziphansi.

• Ukushisa okuphansi noma okuphezulu okusebenzayo.

• Simple futhi nezimo ukusebenza.

• Ukugcinwa okuncane.

• Ikhwalithi yomkhiqizo ehambisanayo.

• Isifudumezi esiqukethe okomkhumbi esikhiqizweni esikhiqiza ubuncane besikhala sendawo.

Imiklamo yokushisa ye-induction ayatholakala ukuze ahambisane nemikhumbi yensimbi kanye namathangi amafomu amaningi namajamo ekusetshenzisweni kwamanje. Kusuka kuma-centremetres ambalwa kuya kumamitha amaningana ububanzi noma ubude. Insimbi emnene, egqoke insimbi emnene, insimbi engagqwali eqinile noma imikhumbi engeyona eyensimbi konke kungashiswa ngempumelelo. Ngokuvamile kunconywa ubuncane bodonga obungu-6mm.

Imiklamo yokulinganisa amayunithi isukela ku-1KW kuye ku-1500KW. Ngamasistimu wokushisa we-induction awukho umkhawulo ekufakweni kokuqina kwamandla. Noma imuphi umkhawulo okhona ubekwa ngumthamo omkhulu wokumunca ukushisa womkhiqizo, inqubo noma izici zensimbi ezakhiwe ngodonga lomkhumbi.

Ukushisa kwe-induction kufaka zonke izinto ezilula zikagesi ezithathwe ngqo enqubeni futhi zaguqulwa zashisa ngqo lapho kudingeka khona. Njengoba ukufudumeza kwenzeka ngqo odongeni lomkhumbi lapho kuxhumana nomkhiqizo futhi ukulahleka kokushisa kuphansi kakhulu, uhlelo lusebenza kahle kakhulu (kufika ku-90%).

Ukushisa kwe-induction kunikeza izinzuzo eziningi kakhulu ezingatholakali ngezinye izindlela futhi kunikeza ukusebenza okuthuthukile kokukhiqizwa kwezitshalo nezimo zokusebenza ezingcono ngoba akukho ukuphuma okukhulu kokushisa ezindaweni ezizungezile.

Izimboni ezijwayelekile ezisebenzisa ukufudumeza kwenqubo yokwenziwa:

• Ama-reactor namaketela

• Ukunamathela nokunamathisela okukhethekile

• Amakhemikhali, igesi kanye namafutha

• Ukulungiswa kokudla

• Ukuqedwa kwe-Metallurgical nensimbi

• Ukulungiselela Ukushisela Ukushisa

• Ukugqoka

• Ukushisa kwesikhunta

Ukulinganisa nokungalingani

• Umhlangano Wokushisa

• Ukomiswa kokudla

• Ukushisa Uketshezi Lwamapayipi

• Ukushisa kweTank & Vessel nokuvala izinto

Ukuhlelwa kwe-HLQ Induction In-Line Heater kungasetshenziselwa izinhlelo zokusebenza kufaka phakathi:

• Ukushisa komoya nokwegesi kokuCubungula ngamakhemikhali nokudla

• Ukushisa Amafutha Okushisayo Kwenqubo Namafutha Edliwayo

• I-Vaporising ne-Superheating: Ukukhuphula umusi osheshayo, izinga lokushisa eliphansi neliphezulu / ingcindezi (kufika ku-800ºC kubha eyi-100)

Amaphrojekthi wangaphambilini we-Vessel ne-Continuous Heater afaka:

Ama-Reactors nama-Kettles, ama-Autoclaves, Izitsha Zokucubungula, Ukugcina Nokubeka Amathangi, Amabhavu, Amavoti Namabhodwe Asekhona, Izitsha Zokucindezela, Ama-Vapourisors nama-superheater, Ama-Heat Exchange, ama-Rotary Drums, Amapayipi, Izitsha Ezifudumeza Uphethiloli Ezimbili

Iphrojekthi yangaphambilini ye-In-Line Heater ifaka:

Izifudumezi Esizishisa Ngokushisa Esiphezulu, Izifudumezi Zomoya Ezivuselelayo, Amafutha Okuthambisa Amafutha, Amafutha Okudliwayo Namafutha Okupheka Amafutha, Izifudumezi zegesi kufaka phakathi ama-heater eNitrogen, Nitrogen Argon kanye neCatalytic Rich Gas (CRG).

Ukushisa ukushisa kuyindlela engeyona yokuxhumana yokushisa okhetha ukusebenzisa izinto ezisebenza ngogesi ngokusebenzisa amandla kazibuthe ashintshanayo ukwenza amandla kagesi, aziwa ngokuthi yi-eddy current, ezintweni, ezaziwa njenge-susceptor, ngaleyo ndlela afudumeze i-susceptor. Ukushisa kwe-induction kusetshenziswe embonini ye-metallurgical iminyaka eminingi ngenhloso yokushisa izinsimbi, isb. Ukuncibilika, ukucwenga, ukwelapha ukushisa, ukuwelda nokufaka i-soldering. Ukushisa kwe-induction kwenziwa kumafrikhwensi amaningi, kusuka kumafrikhthi we-AC powerline aphansi njengama-50 Hz kuze kufike kumafrikhwensi amashumi we-MHz.

Kumvamisa wokungeniswa onikeziwe ukusebenza kahle kokushisa kwenkambu yokungenisa kuyanda lapho indlela ende yokuqhuba ikhona entweni. Izingcezu ezinkulu zomsebenzi eziqinile zingashiswa ngamaza aphansi, kuyilapho izinto ezincane zidinga amaza aphezulu. Ukuze into enosayizi inikwe ukufudunyezwa, imvamisa iphansi kakhulu inikezela ukufudumeza okungasebenzi kahle ngoba amandla enkambu yokungenisa awakhiqizi umfutho ofunwayo wemisinga ye-eddy entweni. Imvamisa ephezulu kakhulu, ngakolunye uhlangothi, ibangela ukufudumeza okungalingani ngoba amandla asenkambeni yokungeniswa awangeni entweni futhi imisinga eddy ifakwa kuphela ebusweni noma eduze. Kodwa-ke, ukufudumeza kokungeniswa kwezakhiwo zensimbi ezivuthayo kagesi akwaziwa kubuciko bangaphambilini.

Izinqubo zobuciko zangaphambilini zokuphendula kwesigaba segesi zidinga ukuthi i-catalyst ibe nendawo ephezulu ukuze ama-molecule egesi asebenzayo abe nokuxhumana okuphezulu nendawo yokuthwebula. Izinqubo zobuciko zangaphambilini zivame ukusebenzisa okokusebenza okunomhlwenga noma izinhlayiya ezincane ezincane, ezisekelwa ngokufanele, ukufeza indawo edingekayo. Lezi zinqubo zobuciko zangaphambilini zincike ekwenziweni, imisebe noma ukuhanjiswa ukuze kuhlinzekwe ukushisa okudingekayo ku-catalyst. Ukufeza ukukhetha okuhle kokuphendula kwamakhemikhali zonke izingxenye zama-reactants kufanele zithole ukushisa okufanayo kanye nemvelo ethintekayo. Ukuze kuphendulwe ukuphela kwamandla, isilinganiso sokulethwa kokushisa ngakho-ke sidinga ukufana ngangokunokwenzeka kulo lonke ivolumu yombhede okhandlayo. Kokubili ukuqhutshwa, kanye ne-convection, kanye nemisebe, kukhawulelwe ngokwemvelo emandleni abo okunikeza isilinganiso esidingekayo nokufana kokulethwa kokushisa.

I-GB Patent 2210286 (i-GB '286), ejwayelekile kubuciko bangaphambilini, ifundisa ukufaka izinhlayiya ezincane ze-catalyst ezingahambisani nogesi kusekelo lwensimbi noma lokusebenzisa i-catalyst ukuze ikwenze usebenze kahle ngogesi. Ukwesekwa kwensimbi noma okokusebenza kwe-doping kufakwa ngaphakathi futhi kushisa okuvuselelayo. Leli patent lifundisa ukusetshenziswa komgogodla we-ferromagnetic odlula maphakathi nombhede wokudonsa. Izinto ezithandwayo zomgogodla we-ferromagnetic yi-silicon iron. Yize ilusizo ekuphenduleni kuze kufike cishe kuma-degree angama-600 C., izinto zokusebenza ze-GB Patent 2210286 zinenkinga enkulu emazingeni okushisa aphezulu. Ukutholakala kwamandla kazibuthe womgogodla we-ferromagnetic kuzokwehla kakhulu emazingeni okushisa aphezulu. Ngokusho kuka-Erickson, CJ, “Handbook of Heating for Industry”, amakhasi 84-85, amandla kazibuthe wensimbi aqala ukwehla abe ngu-600 C futhi adlule ngempumelelo ngo-750 C. Njengoba, ekuhlelweni kuka-GB '286, amandla kazibuthe Inkambu embhedeni wokudonsa incike ekuthambekeni kwamandla kazibuthe womgogodla we-ferromagnetic, lelo lungiselelo ngeke lishise ngempumelelo isisusa emazingeni okushisa angaphezu kuka-750 C, ingasaphathwa eyokufika kokukhulu kune-1000 C edingekayo ekukhiqizeni i-HCN.

Izinto ezisetshenziswayo ze-GB Patent 2210286 nazo zikholelwa ukuthi azikulungele ukwenziwa kwe-HCN. I-HCN yenziwa ngokuphendula i-ammonia negesi ye-hydrocarbon. Kuyaziwa ukuthi i-iron ibangela ukubola kwe-ammonia emazingeni okushisa aphakeme. Kukholakala ukuthi i-iron ekhona kumgogodla we-ferromagnetic kanye nasekwesekeni kokuqina ngaphakathi kwegumbi lokuphendula le-GB '286 kungadala ukubola kwe-ammonia futhi kungavimbela, esikhundleni sokukhuthaza, ukusabela okufunwayo kwe-ammonia nge-hydrocarbon ukwakha i-HCN.

IHydrogen cyanide (HCN) iyikhemikhali elibalulekile elisetshenziswa kakhulu ezimbonini zamakhemikhali nezimayini. Isibonelo, i-HCN yinto eluhlaza yokwenziwa kwe-adiponitrile, i-acetone cyanohydrin, i-sodium cyanide, kanye nabaxhumanisi ekwenziweni kwezibulala-zinambuzane, imikhiqizo yezolimo, ama-chelating agents kanye nokuphakelwa kwezilwane. I-HCN iwuketshezi olunobuthi kakhulu olubila kuma-26 degrees C, futhi ngenxa yalokho, lukhonjelwe emithethweni eqinile yokupakisha nokuhamba. Kwezinye izinhlelo zokusebenza, i-HCN iyadingeka ezindaweni ezikude kude nezindawo ezinkulu zokukhiqiza ze-HCN. Ukuthunyelwa kwe-HCN ezindaweni ezinjalo kubandakanya izingozi ezinkulu. Ukukhiqizwa kwe-HCN ezindaweni ezizosetshenziswa kuzo kungavikela izingozi ezitholakala ekuthuthweni, ekugcineni nasekuphatheni kwayo. Ukukhiqizwa okuncane esizeni kwe-HCN, kusetshenziswa izinqubo zobuciko zangaphambili, bekungeke kube nokwenzeka kwezomnotho. Kodwa-ke, isikali esincane, kanye nesilinganiso esikhulu, ukukhiqizwa kwesiza kwe-HCN kuyenzeka ngokwezobuchwepheshe nangokwezomnotho kusetshenziswa izinqubo nezinto ezisetshenziswayo zalokhu okusunguliwe.

I-HCN ingakhiqizwa lapho izinhlanganisela eziqukethe i-hydrogen, i-nitrogen, ne-carbon zihlanganiswa emazingeni okushisa aphezulu, noma zingenayo i-catalyst. Isibonelo, i-HCN ivame ukwenziwa ukusabela kwe-ammonia ne-hydrocarbon, ukusabela okuphela kakhulu emzimbeni. Izinqubo ezintathu zokuhweba zokwenza i-HCN yi-Blausaure aus Methan und Ammoniak (BMA), i-Andrussow, nezinqubo zeShawinigan. Lezi zinqubo zingahlukaniswa ngendlela yokukhiqiza ukushisa nokudlulisa, nokuthi i-catalyst isetshenzisiwe yini.

Inqubo ye-Andrussow isebenzisa ukushisa okwenziwe ukushiswa kwegesi ye-hydrocarbon ne-oxygen ngaphakathi kwevolumu yesikhungo ukupha ukushisa kokuphendula. Inqubo ye-BMA isebenzisa ukushisa okwenziwe ngenqubo yomlilo yangaphandle ukushisa indawo engaphandle yezindonga zesiphenduli, yona yona efudumeza ingaphakathi lezindonga zokuphendula futhi ngaleyo ndlela inikeze ukushisa kokuphendula. Inqubo yeShawinigan isebenzisa amandla kagesi ageleza ngama-electrode embhedeni ophuzwayo ukuhlinzeka ukushisa kokuphendula.

Enqubeni ye-Andrussow, inhlanganisela yegesi yemvelo (ingxube yegesi ye-hydrocarbon ephezulu e-methane), i-ammonia, ne-oxygen noma nomoya kuyasetshenziswa lapho kukhona i-platinum catalyst. I-catalyst ngokuvamile iqukethe izingqimba eziningi ze-platinum / rhodium wire gauze. Ubuningi bomoya-mpilo bokuthi ukushisa okuyingxenye kwama-reactants kunika amandla anele ukushisa ama-reactants ekushiseni okusebenzayo okungaphezu kuka-1000 ° C. kanye nokushisa okudingekayo kokuphendula kokwakheka kwe-HCN. Imikhiqizo yokuphendula yi-HCN, H2, H2O, CO, CO2, futhi ilandelela amanani ama-nitrites aphezulu, okumele ahlukaniswe.

Enqubeni ye-Andrussow, inhlanganisela yegesi yemvelo (ingxube yegesi ye-hydrocarbon ephezulu e-methane), i-ammonia, ne-oxygen noma nomoya kuyasetshenziswa lapho kukhona i-platinum catalyst. I-catalyst ngokuvamile iqukethe izingqimba eziningi ze-platinum / rhodium wire gauze. Ubuningi bomoya-mpilo bokuthi ukushisa okuyingxenye kwama-reactants kunika amandla anele ukushisa ama-reactants ekushiseni okusebenzayo okungaphezu kuka-1000 ° C. kanye nokushisa okudingekayo kokuphendula kokwakheka kwe-HCN. Imikhiqizo yokuphendula yi-HCN, H2, H2O, CO, CO2, futhi ilandelela amanani ama-nitrites aphezulu, okumele ahlukaniswe.

Enqubeni ye-BMA, inhlanganisela ye-ammonia ne-methane igeleza ngaphakathi kwamashubhu e-ceramic angenayo impophoma enziwe ngezinto zokushisa eziphikisayo. Ingaphakathi leshubhu ngalinye lifakwe ngaphakathi noma ligcwele izinhlayiya ze-platinum. Amashubhu abekwa esithandweni sokushisa okuphezulu futhi afudunyezwe ngaphandle. Ukushisa kwenziwa ngodonga lwe-ceramic kuya ku-catalyst surface, okuyingxenye ebalulekile yodonga. Ukuphendula kuvame ukwenziwa ngo-1300 ° C. njengoba ama-reactants axhumana ne-catalyst. Ukufudumala kokushisa okudingekayo kuphezulu ngenxa yokushisa okuphezulu okuphendulayo, ukushisa okukhulu kokuphendula, kanye nokuthi ukupheka kobuso be-catalyst kungenzeka ngaphansi kwezinga lokushisa lokuphendula, okuvimbela i-catalyst. Njengoba ithubhu ngayinye icishe ibe ngu-1 ″ ububanzi, kudingeka inani elikhulu lamashubhu ukuhlangabezana nezidingo zokukhiqiza. Imikhiqizo yokusabela yi-HCN ne-hydrogen.

Enqubeni yeShawinigan, amandla adingekayo ekuphenduleni kwenhlanganisela equkethe i-propane ne-ammonia anikezwa ngamandla kagesi ageleza phakathi kwama-electrode acwiliswe embhedeni oketshezi wezinhlayiya ze-coke non-catalytic. Ukungabikho kwe-catalyst, kanye nokungabikho komoya-mpilo noma umoya, kwinqubo yeShawinigan kusho ukuthi ukuphendula kufanele kuqhutshwe emazingeni okushisa aphakeme kakhulu, imvamisa kudlula ama-degree angama-1500 C. Amazinga aphezulu okushisa adinga ukubeka izingqinamba ezinkulu kakhulu izinto zokwakha zenqubo.

Ngenkathi, njengoba kudalulwe ngenhla, kuyaziwa ukuthi i-HCN ingakhiqizwa ukusabela kwe-NH3 kanye negesi ye-hydrocarbon, efana ne-CH4 noma i-C3H8, lapho kukhona i-Pt group catalyst yensimbi, kusenesidingo sokwenza ngcono ukusebenza kahle izinqubo ezinjalo, nezinye ezihlobene nazo, ukuze kuthuthukiswe ezomnotho zokukhiqizwa kwe-HCN, ikakhulukazi ukukhiqizwa okuncane. Kubaluleke kakhulu ukunciphisa ukusetshenziswa kwamandla nokuqhamuka kwe-ammonia ngenkathi kukhulisa izinga lokukhiqiza le-HCN ngokuqhathanisa nenani le-catalyst yensimbi eyigugu esetshenzisiwe. Ngaphezu kwalokho, i-catalyst akufanele iphazamise ukukhiqizwa kwe-HCN ngokukhuthaza ukusabela okungathandeki njengokupheka. Ngaphezu kwalokho, kuyadingeka ukwenza ngcono umsebenzi nempilo yama-catalysts asetshenziswe kule nqubo. Ngokuphawulekayo, ingxenye enkulu yokutshalwa kwezimali ekukhiqizeni i-HCN iku-catalyst yeqembu le-platinum. Ukuqanjwa kwamanje kushisa i-catalyst ngqo, kunokuba kube ngokungaqondile njengakubuciko bangaphambilini, futhi ngaleyo ndlela kufezekiswe lezi desiderata.

Njengoba kuxoxwe ngaphambili, ukufudumeza kokufakwa okuvama okuphansi kuqhathaniswa nokwaziwa ngokuhlinzeka ngokufana okuhle kokulethwa kokushisa emazingeni aphezulu wamandla ezintweni ezinemigwaqo ende kagesi yokuhamba. Lapho unikeza amandla okuphendula kumandla wegesi we-endothermic phase catalytic, ukushisa kudinga ukuhanjiswa ngqo ku-catalyst ngokulahleka kwamandla okuncane. Izidingo zokulethwa kokushisa okufanayo futhi okusebenzayo endaweni ephezulu, enendawo evumelana negesi kubonakala kungqubuzana namandla okushisa wokungeniswa. Ukuqanjwa kwamanje kusekelwe emiphumeleni engalindelekile etholwe ngokucushwa kwesiphenduli lapho i-catalyst inefomu lesakhiwo senoveli. Leli fomu lihlanganisa izici ze: 1) ubude bendlela yokuhamba kagesi esebenza kahle, esiza ukufudumeza okusebenzayo okusebenzayo kwe-catalyst ngendlela efanayo, kanye ne-2) i-catalyst enendawo ephezulu; lezi zici ziyasebenzisana ukwenza lula ukuphendula kwamakhemikhali endothermic. Ukushoda okuphelele kwensimbi egumbini lokuphendula kusiza ukukhiqizwa kwe-HCN ngokuphendula kwe-NH3 kanye negesi ye-hydrocarbon.

Njengoba kuxoxwe ngaphambili, ukufudumeza kokufakwa okuvama okuphansi kuqhathaniswa nokwaziwa ngokuhlinzeka ngokufana okuhle kokulethwa kokushisa emazingeni aphezulu wamandla ezintweni ezinemigwaqo ende kagesi yokuhamba. Lapho unikeza amandla okuphendula kumandla wegesi we-endothermic phase catalytic, ukushisa kudinga ukuhanjiswa ngqo ku-catalyst ngokulahleka kwamandla okuncane. Izidingo zokulethwa kokushisa okufanayo futhi okusebenzayo endaweni ephezulu, enendawo evumelana negesi kubonakala kungqubuzana namandla okushisa wokungeniswa. Ukuqanjwa kwamanje kusekelwe emiphumeleni engalindelekile etholwe ngokucushwa kwesiphenduli lapho i-catalyst inefomu lesakhiwo senoveli. Leli fomu lihlanganisa izici ze: 1) ubude bendlela yokuhamba kagesi esebenza kahle, esiza ukufudumeza okusebenzayo okusebenzayo kwe-catalyst ngendlela efanayo, kanye ne-2) i-catalyst enendawo ephezulu; lezi zici ziyasebenzisana ukwenza lula ukuphendula kwamakhemikhali endothermic. Ukushoda okuphelele kwensimbi egumbini lokuphendula kusiza ukukhiqizwa kwe-HCN ngokuphendula kwe-NH3 kanye negesi ye-hydrocarbon.

I-Induction Heating Power Calculation

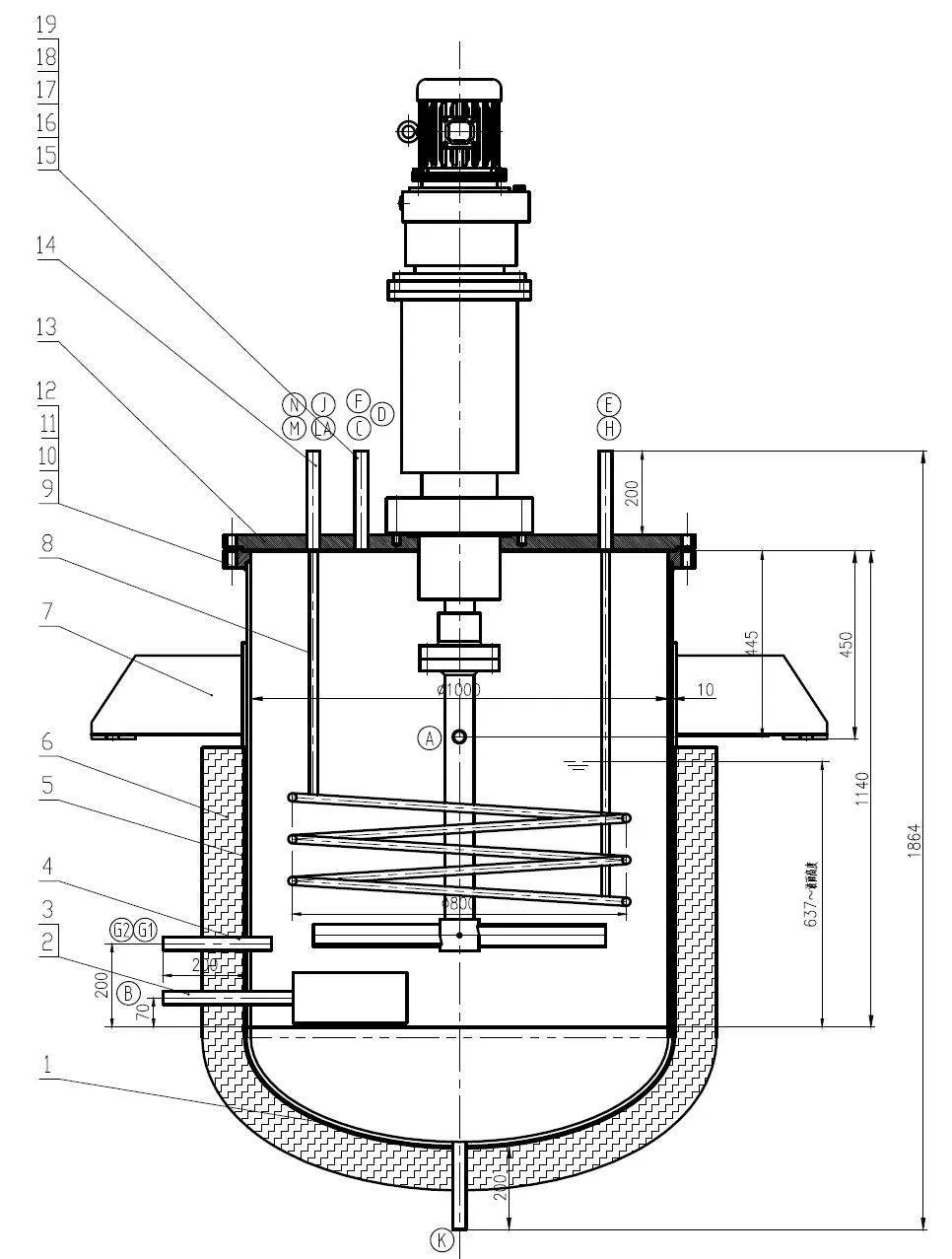

Isibonelo: I-Atmospheric Pressure Reactor

Material: 304 insimbi engagqwali

Ubukhulu: 2m(ububanzi)*3m(ubude)

Ubukhulu bodonga: 8mm

Isisindo se-reactor: 1000kg (approx.)

Umthamo: 7m3

Isisindo sempahla ewuketshezi: 7t

Umthamo wokushisa othize wezinto eziwuketshezi: 4200J/kg*ºC

Izimfuneko: ukushisa kusuka ku-20ºC kuya ku-280ºC phakathi namahora angu-3

Ifomula yokubala ukushisa: Q=cm▲t+km

Ifomula yokubala amandla: umthamo wokushisa othize J/(kg*ºC)×umehluko wezinga lokushisaºC×isisindo KG ÷ isikhathi S = amandla W

i.e. P=4200J/kg*ºC×(280-20)ºC×7000kg÷10800s=707777W≈708kW

Isiphetho

Amandla etiyetha angu-708kW, kodwa amandla angempela avame ukukhuphuka ngo-20% ngenxa yokucabangela ukulahlekelwa ukushisa, okungukuthi, amandla angempela angu-708kW*1.2≈850kW. Kudingeka amasethi ayisikhombisa esistimu yokushisisa engu-120kW njengenhlanganisela.

Induction Ukushisa imikhumbi ophendulayo

Induction Ukushisa imikhumbi ophendulayo