Isithandane se-Iron Melting

Incazelo

Isithandane Sokuvutha Kwensimbi | Isithandwa Sokuvutha Isitini Sokushisa I-Iron

Incazelo Yokukhiqiza:

I-1) Ukufakela kwefrimu ephakathi kwensimbi ecibilikisa isithando somlilo

I-2) Uhlelo olugcwele lokulawula idijithali ngokunemba okuphakeme

I-3) Ukuxuba insimbi yensimbi, insimbi, insimbi, insimbi engagqwali, ithusi, i-aluminium

4) 0.15-20 amathani amandla

I-5) Ukukhishwa kwamandla okuqhubekayo, ukuqubuka okusheshayo, ukonga okuhle kagesi.

I-6) I-shell shell isithando somlilo, ukugubha amanzi.

I-3.Ukusetshenziswa: Imfucumfucu yensimbi evuthayo isithando somlilo Esetshenziswa kabanzi ekuqubheni insimbi, insimbi, ithusi, i-aluminium kanye ne-alloy, inomphumela omuhle wokuqhafaza, umphumela omuhle wokulondoloza ugesi, ukufana okuhle kwezinto zensimbi, ukulahleka okuncane kokushisa, ukuphakama okushisa okusheshayo, ukulawula okulula okushisa, kuyafaneleka kuzo zonke izinhlobo zensimbi ecibilika.

I-4.Izinkampani nezinzuzo:

I-1) Ukukhishwa kwamandla okuqhubekayo, ukuqubuka okusheshayo, ukonga okuhle kagesi.

I-2) Isitayela se-Zero-voltage sweep-frequency isqala, ivumelanisa nezidingo zokuqala njalo.

I-3) Imisebenzi yokuvikela ephelele, njengokuvikelwa kwe-overcurrency, ukuvikelwa komkhumbi, ukuvikelwa kwamanje, ukuvikelwa kwamandla, ukuvikelwa kwamanzi, nokuvikelwa okuzenzakalelayo, imishini isebenza ngokuqiniseka ngaphansi kokuqinisekisa ukujula isivinini.

4) Kulula ukusebenza, efanelekayo yonke inqubo yokukhipha.

Izici zomkhiqizo

-Kufanele

Isikhathi sokuncibilika kwesithando esisodwa singashesha njenge- <40 imizuzu! Isici samandla esithandweni sihlala sifinyelelwa ezweni eliphakeme kakhulu (≧ 0.96)!

Ngesikhathi se-smelting, kungakhathaliseki ukuthi isimo sesithando sishintsha kanjani, amandla okuvama okuphakathi ahlinzeka ngaso sonke isikhathi amandla okuphuma. Lokhu kusho ukuthi, ngaphandle kokulungiswa kwebhuku lomqhubi, yonke inqubo esuka ekufubeni kuze kube sekupheleni, ukunikezwa kwamandla okuvama okuphakathi kuzokwazi ukuletha amandla amakhulu esithandweni somlilo.

-Ukugcina ukulondoloza

Inkinga yokuncintisana kwamandla kagesi (cast iron mayelana 530 kwh / T)! Uma kuqhathaniswa ne-common parallel power inverter amandla okusindisa mayelana ne-20%.

-Harmonic

Ukufeza i-harmonic yamazwe ngamazwe kanye ne-voltage engavumelekile!

Ukusebenzisa uchungechunge lwamandla okuvuselela amandla okugcwele, konke okusebenzayo kokuvuselela kuhlale kuvulekile ngokugcwele (okulingana nomhleli wokulungisa i-diode), akukhiqizi i-harmonic ephakeme, okuyisisekelo okungcoliseki ku-inethiwekhi yamandla, akuthinti ukusebenza kwe-substation amandla okuvuselela amandla amandla.

-Coil

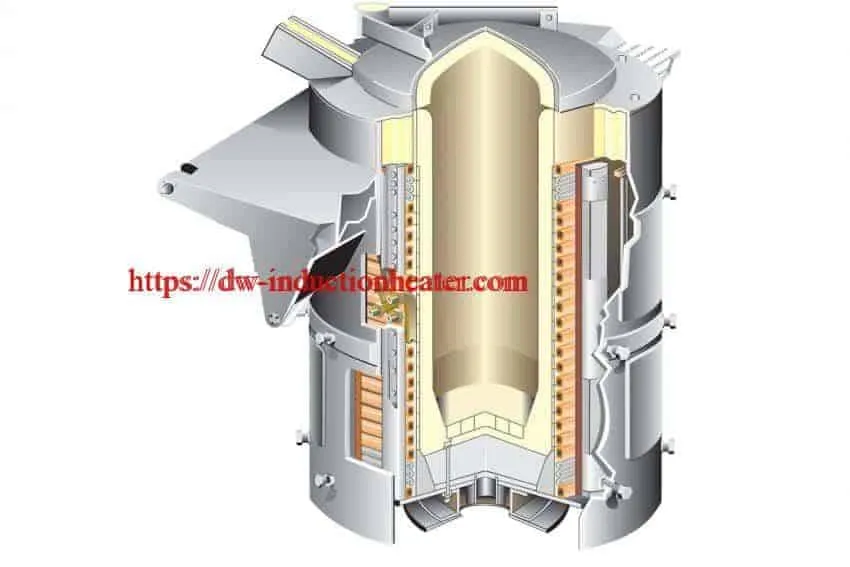

I-design-coil ye-induction coil design inganciphisa ngokuphumelelayo ukulahlekelwa kwekhoyili.

Ukukhishwa kwe-coil kokulahlekelwa kwama-furnace ama-furnace ama-akhawunti angu-25% wamandla angqikithi, ngakho-ke ukuklama kwesayensi nokwengqondo kwe-coil kubaluleke kakhulu. Lapho siklama ikhoyili, samukela ithusi eliphakeme le-TU1 lensimbi eno-aluminium ithusi, futhi iqola le-coil lamukela ukukhwabanisa kwesiliva esiphezulu, ephethe ukulahlekelwa okuphezulu nokulahlekelwa okuncane. Ukuze uqiniseke ukuthi ukuhamba okuhamba phambili kunakho konke, izinto zokugxila zifakwe emkhatsini wokuphenduka, izinga lokuxilonga lithuthukisiwe futhi kutholakala ukusebenza kahle okukhulu kagesi kagesi.

Isitebele & Ukuvikelwa Kwemvelo

-Stabilization

Ukukhethwa kwezinto eziphezulu eziphezulu ukuqinisekisa ukuzinza kwemishini.

①Ishicilelwe i-hose high carbon-free hose kanye ne-304 insimbi engagqwali insimbi: ihlala njalo!

②I-fibre transmission transmission inverter trigger ipulisa signal plate: ikhono elinamandla lokuphikisana nokusebenza okuzinzile

③I-high quality ekhethekile ye-platform ye-Thyristor, i-radiator-type square cooling radiator (HengYang Patent No.): sebenzisa okulula kakhulu!

④I-capacitor yomzimba: isakhiwo esizungezile, isilondolozi esiphezulu se-shell yangaphandle, esebenzisa amandla aphezulu we-magnesium aluminium alloy, anti-corrosion ngaphezulu futhi ehlala isikhathi eside.

⑤Ukucubha ibha yethusi: Okukhulu, ithusi elimnyama linganciphisa ukushisa nokushisa amandla! I-Copper sandblasted surface and anti-oxidation, i-contact surface iyasebenza kakhulu, ukubukeka akupheli futhi kwenza kube mnandi!

⑥Ukushintshwa (ukushintsha) ushintsho: lapho isithando somlilo sishintshwa noma siphendulwa, kungenzeka ukulawula ukwehluleka kwamandla kwesithando somlilo ngaphandle kokuphazamisa ukusebenza okuvamile kwesithando somlilo. Umklamo wokuphepha nokuzihlanganisa.

⑦Phatha uhlelo lokushintshanisa ukushisa (HengYang Patent No.): ukuqinisekisa ukushisa kwamanzi okupholisa emishini, nokuvimbela amanzi angaphandle angaphandle ukungena emandleni. Ukunakekela ukunciphisa ukuhluleka kwemishini.

-Ukuvikeleka kokuvikeleka

I-cast iron melitng induction furnace isebenzisa isivunguvungu kanye ne-side suction heat- preservation furnace cover, dust hood (ring) ngomoya othile omunca uthuli, igesi yemfucumfucu eyenziwe ngokuncibilikisa, ifinyelele futhi ithuthukise umphumela wokukhishwa kokukhishwa, ukuhlangabezana nezidingo zomthelela wezemvelo umklamo wokuhlola.

Uhlobo Oluyinhloko Nezingqinamba Zezobuchwepheshe:

| Ukufaka amandla (50 / 60HZ) | Okukhipha amandla | Amandla wezindleko zamathani (KWH / T) | ||||||||||||

| Uhlobo lwe-EAF Isithando somlilo sikaMandla | Amandla alinganisiwe (KW) | I-voltage engenayo (V) | I-line yamanje engenayo (A) | Ukuvuselela inombolo ye-pulse | Umthamo wokuguqula i-Rectifier (KVA) | I-vol voltage (V) | Amanje okuqondile (A) | Imvamisa yevolumu yamandla (V) | Imvamisa ephakathi KHZ | Isikhathi sokukha amanzi (Min) | Insimbi | Ithusi elibomvu | Brass | Aluminum |

| I-GW – 0.35T | 250 | 380 | 400 | 6 | I-315 yesigaba esithathu | 500 | 500 | 750 | 1 | 20-45 | 560 | 420 | 390 | 540 |

| I-GW – 0.5T | 350 | 380 | 560 | 6 | I-400 yesigaba esithathu | 500 | 700 | 750 | 0.8 | 30-50 | 550 | 410 | 380 | 530 |

| I-GW – 0.75T | 500 | 380 | 800 | 6 | I-630 yesigaba esithathu | 500 | 1000 | 750 | 0.8 | 40-50 | 550 | 410 | 380 | 530 |

| I-GW – 1T | 800 | 380

750 |

1280

656 |

6

6 |

I-1000 yesigaba esithathu

I-1000 yesigaba esithathu |

500

990 |

1600

808 |

750

1480 |

0.7 | 40-50 | 540 | 400 | 370 | 520 |

| I-GW – 1.5T | 1000 | 380

750 |

800

820 |

12

6 |

I-1250 yesigaba esithathu

I-1250 yesigaba esithathu |

500

990 |

1000

1010 |

750

1480 |

0.7 | 40-60 | 530 | 390 | 360 | 510 |

| I-GW – 2T | 1400 | 750

750 |

1148

574 |

6

12 |

I-1800 yesigaba esithathu

I-1800 yesigaba esithathu |

990

990 |

1414

707 |

1480

1480 |

0.5 | 45-60 | 520 | 380 | 350 | 500 |

| I-GW – 3T | 2000 | 750 | 820 | 12 | I-2500 yesigaba esithathu | 990 | 1010 | 1480 | 0.5 | 50-70 | 510 | 370 | 340 | 490 |

| I-GW – 5T | 3000 | 950 | 1140 | 12 | I-4000 yesigaba esithathu | 1260 | 1190 | 1900 | 0.3 | 50-80 | 500 | 360 | 330 | 480 |

| I-GW – 10T | 6000 | 950 | 2280 | 12 | I-8000 yesigaba esithathu | 1260 | 2380 | 1900 | 0.3 | 50-90 | 490 | 350 | 320 | 470 |

| I-GW – 15T | 8000 | 950 | 1520 | 24 | I-10000 yesigaba esine | 1260 | 1590 | 1900 | 0.3 | 50-90 | 480 | 340 | 310 | 460 |

| I-GW – 20T | 10000 | 950 | 1900 | 24 | I-12500 yesigaba esine | 1260 | 1980 | 1900 | 0.25 | 50-90 | 470 | 330 | 300 | 450 |

| I-GW – 30T | 15000 | 950 | 2850 | 24 | I-20000 yesigaba esine | 1260 | 2980 | 1900 | 0.25 | 50-90 | 470 | 330 | 300 | 450 |

| Ukushisa okungaphakathi kwesithando: Insimbi 1650, Isimbi yensimbi 1450, Ithusi elibomvu 1150, Brass 1000, Aluminium 700, Zinc 400 | ||||||||||||||

※ Amandla kagesi Ukufakwa kwe-iron enqenqenqenqenqenqenqeni isekelwe ngobuningi bensimbi ye-7.8 (isibalo se-aluminium yi-2.7, ngakho-ke i-aluminium isisindo esifanayo: amandla afanayo afanayo, futhi amandla adinga x izikhathi izikhathi ezingu-3 esithandweni somlilo)

※ Isikhathi sokuqhakazila kanye namathani okusebenzisa amandla kubalulekile ubudlelwane obunamandla nemishini ehambisanayo, isimo sezinto ezibonakalayo, ubuningi bokubambisana, ukuqeqeshwa kwabasebenzi,

※ Ngefomu elingenhla, i- "ton power ukusetshenziswa (kwh / T)" uchungechunge olusha lokusetshenziswa kwamandla, oluzodla u-15% noma ngaphezulu kokunikezwa kwamandla ku-Common parallel IF power supply

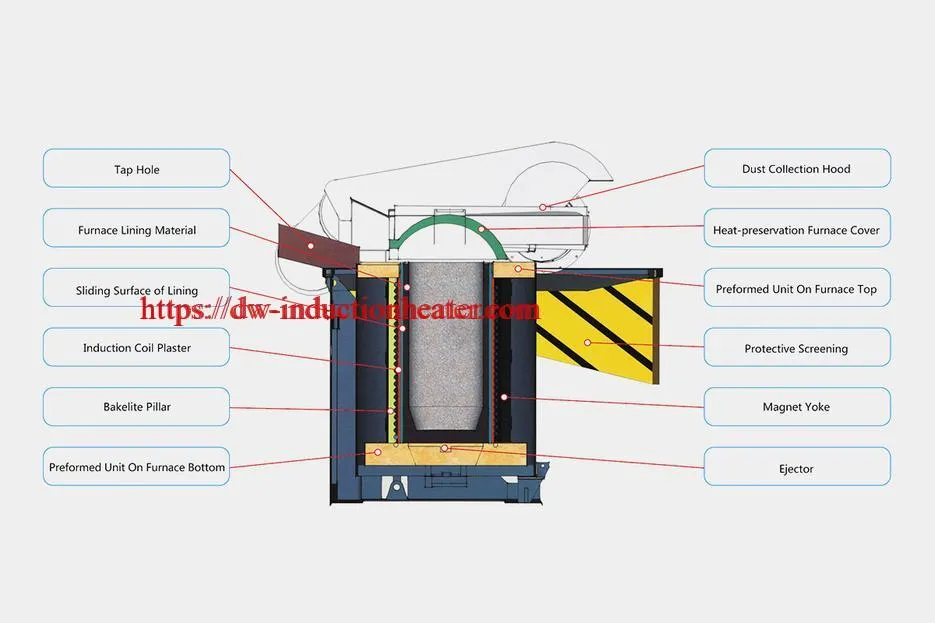

Configuration Ukumiswa kwesithando sensimbi yensimbi yensimbi: ukunikezwa kwamandla okuvama okuphakathi, ikhabethe le-capacitor, umzimba womlilo (igobolondo lensimbi noma igobolondo le-aluminium), isiteshi se-hydraulic (noma i-reducer) uhlelo lokutshekisa, ikhebula lokupholisa amanzi njll;

※ Okungaphezulu kukhona idatha yomkhiqizo ojwayelekile, angakwazi ukuklama amandla ahlukene ngokusho kwesidingo somsebenzisi, umkhiqizo ongeyona ejwayelekile ngejubane eliqhakazile.

I-100kg ^ I-5T Industry Induction I-Steel Iron Melting Isibhamu isetshenziswa ngokuyinhloko ekwenzeni insimbi ensimbi, insimbi, insimbi engagqwali, ithusi, ithusi, i-aluminium, igolide, isiliva njll.