uhlelo lokufudumeza komoya lokungeniswa kwamandla

Incazelo

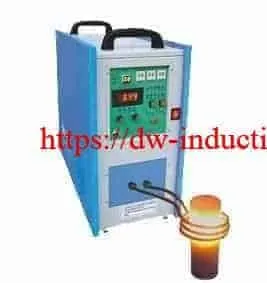

Uhlelo lokushisa lwe-IGBT magnetic induction

Izici eziyinhloko:

- I-IGBT module kanye ne-inverting ubuchwepheshe, ukusebenza kangcono, ukwethembeka okuphakeme izindleko zesondlo esezansi;

- Umjikelezo we-100% womsebenzi, ukusebenza okuqhubekayo kuvunyelwe ekuphumeni kwamandla amakhulu;

- isimo samanje samanje noma samandla njalo singakhethwa ngokufanele ukufezekisa ukushisa okuphezulu;

- ukubonisa ukushisa amandla nokushisa imvamisa yamanje neyinkimbinkimbi;

- imisebenzi eminingi yokubonisa, ngezibonisi ezingaphezu kwamanje, ngaphezu kwamandla, ukwehluleka kwamanzi, ukwehluleka kwesigaba kanye nomfana ongafanelekile njalo njalo, umshini ungavikelwa ekubhubhiseni nemishini kungalungiswa kalula.

- kulula ukufaka, ukufakwa kungenziwa ngumuntu ongenamsebenzi kalula, ukuxhuma kwamanzi namandla kungaphelelwa emaminithini ambalwa.

- isisindo esincane, usayizi omncane.

- ukwakheka nosayizi ohlukile ukufakwa kwe-coil yokushisa kungashintshwa kalula ukushisa izingxenye ezahlukahlukene.

- Izinzuzo ze-model ne timer: amandla kanye nesikhathi sokusebenza isikhathi sokushisa nokugcina isikhathi kungasetshenzwa ngokulandelana, ukuze kutholakale i-curve elula yokushisa, lo modeli uphakanyiswa ukuthi usebenzise ukukhiqizwa kwe-batch ukuthuthukisa ukuphindaphinda.

- amamodeli ahlukanisiwe aklanyelwe ukuhambisana nendawo engcolile, i-generator ingafakwa endaweni ehlanzekile yokwandisa ukuthembeka; ngosayizi omncane nesisindo esincane se-transformer ehlukanisiwe, kulula ukuwasebenzisa emgqeni wokukhiqiza futhi uhlangane kalula ngaphakathi komshini noma indlela yokuhambisa.

| Series | imodeli | Amandla wokufaka max | I-max Max yamanje | Imvamisa ye-Oscillate | Input Voltage | Umjikelezo womsebenzi | |

| MF

. |

I-DW-MF-15 Induction Generator | 15KW | 23A | 1KHz-20KHz Ngokusho kwesicelo | 3phases380V ± 10% | 100% | |

| I-DW-MF-25 Induction Generator | 25KW | 36A | |||||

| I-DW-MF-35Induction Generator | 35KW | 51A | |||||

| I-DW-MF-45 Induction Generator | 45KW | 68A | |||||

| I-DW-MF-70 Induction Generator | 70KW | 105A | |||||

| I-DW-MF-90 Induction Generator | 90KW | 135A | |||||

| I-DW-MF-110 Induction Generator | 110KW | 170A | |||||

| I-DW-MF-160 Induction Generator | 160KW | 240A | |||||

| I-DW-MF-300 Induction Generator | 300KW | 400A | |||||

| I-DW-MF-45 Ukushisa Ukudonsa I-Rod Yokufaka Isithanga | 45KW | 68A | I-1KHz-20KHz | 3phases380V ± 10% | 100% | ||

| I-DW-MF-70 Ukushisa Ukudonsa I-Rod Yokufaka Isithanga | 70KW | 105A | |||||

| I-DW-MF-90 Ukushisa Ukudonsa I-Rod Yokufaka Isithanga | 90KW | 135A | |||||

| I-DW-MF-110 Ukushisa Ukudonsa I-Rod Yokufaka Isithanga | 110KW | 170A | |||||

| I-DW-MF-160 Induction Heating Rod Yokufaka Isithando Somlilo | 160KW | 240A | |||||

| I-DW-MF-15 Induction Melting Furnace | 15KW | 23A | I-1K-20KHz | 3phases380V ± 10% | 100% | ||

| I-DW-MF-25 Induction Melting Furnace | 25KW | 36A | |||||

| I-DW-MF-35 Induction Melting Furnace | 35KW | 51A | |||||

| I-DW-MF-45 Induction Melting Furnace | 45KW | 68A | |||||

| I-DW-MF-70 Induction Melting Furnace | 70KW | 105A | |||||

| I-DW-MF-90 Induction Melting Furnace | 90KW | 135A | |||||

| I-DW-MF-110 Inkokhelo Yokuqothula Isihenqo | 110KW | 170A | |||||

| I-DW-MF-160 Inkokhelo Yokuqothula Isihenqo | 160KW | 240A | |||||

| I-DW-MF-110 Induction Equipment Hardening Equipment | 110KW | 170A | I-1K-8KHz | 3phases380V ± 10% | 100% | ||

| I-DW-MF-160Iuction Equipment Ezikhandlayo | 160KW | 240A | |||||

| HF

. |

I-DW-HF-15 Series | I-DW-HF-15KW | I-15KVA | 32A | I-30-100KHz | Isigaba esisodwa se-220V | 80% |

| I-DW-HF-25 Series | I-DW-HF-25KW-A | I-25KVA | 23A | I-20K-80KHz | 3phases380V ± 10% | 100% | |

| I-DW-HF-25KW-B | |||||||

| I-DW-HF-35 Series | I-DW-HF-35KW-B | I-35KVA | 51A | ||||

| I-DW-HF-45 Series | I-DW-HF-45KW-B | I-45KVA | 68A | ||||

| I-DW-HF-60 Series | I-DW-HF-60KW-B | I-60KVA | 105A | ||||

| I-DW-HF-80 Series | I-DW-HF-80KW-B | I-80KVA | 130A | ||||

| I-DW-HF-90 Series | I-DW-HF-90KW-B | I-90KVA | 160A | ||||

| I-DW-HF-120 Series | I-DW-HF-120KW-B | I-120KVA | 200A | ||||

| I-DW-HF-160 Series | I-DW-HF-160KW-B | I-160KVA | 260A | ||||

| UH

. F .

|

I-DW-UHF-4.5KW | 4.5KW | 20A | I-1.1-2.0MHz | Isigaba esisodwa220V ± 10% | 100% | |

| I-DW-UHF-6.0KW | 6.0KW | 28A | |||||

| I-DW-UHF-10KW | 10KW | 15A | I-100-500KHz | 3phases380V ± 10% | 100% | ||

| I-DW-UHF-20KW | 20KW | 30A | I-50-250KHz | ||||

| I-DW-UHF-30KW | 30KW | 45A | I-50-200KHz | ||||

| I-DW-UHF-40KW | 40KW | 60A | I-50-200KHz | ||||

| I-DW-UHF-60KW | 60KW | 90A | I-50-150KHz | ||||

Izicelo

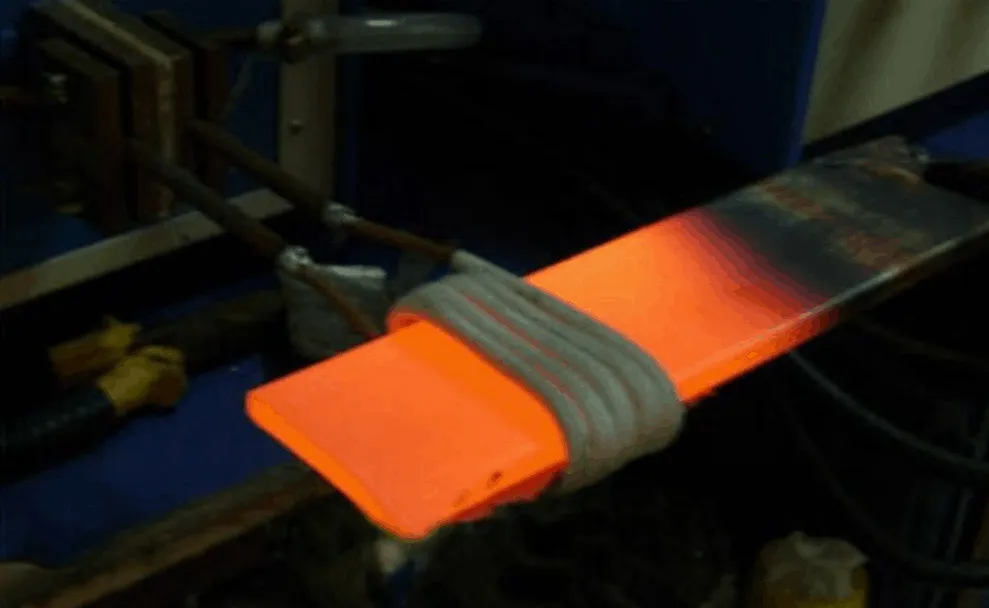

1.Ukushisa (UKWAKHA okushisayo, ukufaka okushisayo nokuncibilikisa)

Induction Hot UKWAKHA ihlose ukuqamba izingcezu zomsebenzi wokushisa okuthile (izinto ezahlukahlukene zidinga amazinga okushisa ahlukile) kwezinye izinhlobo ngokufaka umshini wokwenza ngosizo ngocindezelo lwe-punch, umshini wokufaka noma ezinye izinto, ngezimo, ukukhishwa okushisayo kwekesi lewashi, iwashi flan, isibambo, isikhunta isesekeli, ikhishi netafula ware, ubuciko be-ware, ingxenye ejwayelekile, i-fastener, ingxenye eyenziwe ngomshini, iloksi yethusi, i-rivet, iphini lensimbi nephini.

Ukufakwa okushisayo kubhekisa ekuxhumaneni kwezinsimbi ezahlukahlukene noma izinsimbi ngezinsimbi ezingekho ngaphansi kwento ngokushisa ngokuya ngomgomo wokunweba okushisayo noma ukuncibilikisa okushisayo, ngezehlakalo, ukufakwa kwe-welding komgogodla wethusi we-radiator yekhompyutha eneshidi le-aluminium kanye newebhu yesipikha, inhlanganisela yensimbi nepulasitiki ityhubhu, ukubekwa uphawu kwe-aluminium foil (izinyo lokunamathisela izinyo), i-motor rotor nokufakwa uphawu kwento yokushisa kagesi e-tubular.

Ukuncibilikisa ikakhulukazi kuhlose ukuncibilikisa insimbi ibe wuketshezi ngokusebenzisa ukushisa okuphezulu, okusebenza kakhulu ekuncibilikiseni kwensimbi, insimbi, ithusi, i-aluminium, i-zinc kanye nezinsimbi ezahlukahlukene ezinhle.

Ukwelashwa kwe-2.Heat (ukucima indawo)

Cima i-Hardware namathuluzi ahlukahlukene, njenge-plier, i-wrench, isando, i-ax, amathuluzi okugoqa kanye ne-shear (i-orchard shear).

Cima izinto ezahlukahlukene zezimoto nezithuthuthu, njenge-crankshaft, induku yokuxhuma, iphini le-piston, isondo leketanga, isondo le-aluminium, i-valve, idwala lengalo, idrayivu shaft shaft, shaft encane nemfoloko Amathuluzi kagesi ahlukahlukene, njengamagiya namazembe.

Cima amathuluzi omshini, njengasemgqeni wepayipi lesitimela nomzila wesitimela.

Cima izingxenye ezahlukahlukene zensimbi ye-Hardware nezingxenye ezenziwe ngomshini, njenge-shaft, igiya (isondo leketanga), i-cam, i-chuck kanye ne-clamp njll.

Cima isikhunta se-Hardware, esifana nesikhunta sosayizi omncane, isesekeli sesikhunta nomgodi wangaphakathi wesikhunta

I-3.Welding (i-braze welding, i-soldering yesiliva nokubopha)

Ukushisela amathuluzi ahlukahlukene wokusika okwe-Hardware, njengethuluzi ledayimane, ithuluzi elicasulayo, ithuluzi lokubhola, i-alloy saw blade, i-hard alloy cutter, i-milling cutter, i-reamer, ithuluzi lokuhlela kanye nendawo encane yesikhungo.

Ukushisela igajethi ehlukahlukene yemishini yehadiwe: I-soldering yesiliva kanye Ukukhishwa kwesibalo wezinsimbi ezinhlobonhlobo ezifanayo noma izinhlobo ezahlukahlukene, njenge-hardware yangasese kanye nemikhiqizo yasekhishini, ukufaka ifriji okufakwa esiqandisini, ukuhlobisa isibani, ukunemba kwesikhunta, isibambo sehadiwe, isigaxa seqanda, insimbi ye-alloy nensimbi, insimbi nethusi kanye nethusi nethusi.

Ukushisela phansi kwebhodwe eliyimbumbulu kusebenza ikakhulu ekushisheni kwe-braze okuyindilinga, isikwele kanye nokunye okungajwayelekile kwembiza esezansi. Kuyasebenza nasekushiseni kwe-braze okucacile kwezinye izinsimbi.

Ukushisela i-disc yokushisa kweketela lamanzi ashisayo kagesi ikakhulukazi kubhekisa ekushiseni kwe-braze kwensimbi engagqwali eyisisekelo, ishidi le-aluminium nezinto zokufudumeza kagesi eziyizimo ezahlukahlukene.

3.Annealing (tempering nokushintshashintsha kwezwi)

Ukuncishiswa kwemikhiqizo ehlukahlukene yensimbi engagqwali, efana nebheseni lensimbi engagqwali, ikani elifakiwe kanye nelikhishiwe, umphetho ohlanganisiwe, isinki efakiwe, ishubhu lensimbi engagqwali, i-tableware nenkomishi.

Ukunwetshwa kwezingcezu zomsebenzi wensimbi ezahlukahlukene, njengekholomu yebhola yegalufu, inkomba, ukukhiya ithusi, ukufaka ithusi lensimbi, isibambo sommese wasekhishini, i-blade, ipanini le-aluminium, i-aluminium pail, i-radiator ye-aluminium kanye nemikhiqizo ehlukahlukene ye-aluminium.

Isimiso sokushisa ukukhipha

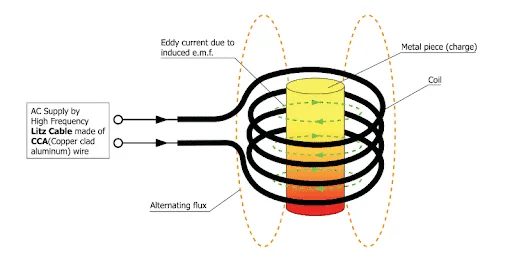

Ukuguqulwa kwamavamisa ukushisa kwe-electromagnetic induction noma ukufudumeza kokungeniswa okufushane kuyindlela yokushisa izinto zensimbi ngokuguqula ukunikezwa kwamandla kagesi wamandla kube kwebanga elithile ngokususelwa kumgomo wokungeniswa kwamandla kagesi. Kusebenza ikakhulu ekusebenzeni okushisayo kwensimbi, ekwelapheni ukushisa, ekushiseni nasekuncibilikeni. Lolu hlobo lwendlela yokushisa luyasebenza nasembonini yokupakisha (njengokufakwa uphawu kwe-aluminium foil esetshenziswa embonini yezokwelapha neyezokudla), okokusebenza kwe-semiconductor (okufana ne-silicon monocrystalline silicon kanye nezingxenye zensimbi ezifudunyeziwe zengilazi ezenzakalelayo).

Isisekelo sohlelo lokushisa lokungeniswa faka ikhoyili yokungeniswa, umthombo wamandla we-AC nezicucu zomsebenzi. I-coil ye-induction ingenziwa ngezimo ezahlukahlukene njengezinto ezahlukahlukene ezifudunyeziwe. Ikhoyili ixhunywe nomthombo wamandla ohlinzeka ngokushintshana kwamanje kwekhoyili. Ukushintshana kwamanje okuphethwe yikhoyili kungadala amandla kazibuthe ashintshanayo adlula ezingxenyeni zomsebenzi ukukhiqiza ukugeleza kwe-eddy njengoba kudingeka ngokushisa.

Izinzuzo zohlelo lokushisa lokungeniswa kwe-manetic

- Ukushisa okusheshayo: isilinganiso esincane sokushisa singaphansi kwesekhondi eli-1 (izinga lokushisa liyatholakala ukuze kulungiswe futhi kulawulwe).

- Ukusabalala okubanzi kokushisa: ingasetshenziselwa ukushisa izingxenye ezahlukahlukene zensimbi (buyisela ikhoyili yokukhipha ekhishwayo njengokushintshwa okuhlukile kokusebenza).

- ukufakwa Easy: ingasetshenziswa uma ixhunywe nomthombo wamandla, ikhoyili yokungeniswa kanye nepayipi lokuhambisa amanzi kanye nepayipi elikhulayo; mncane ngosayizi futhi ulula ngesisindo.

- Ukusebenza okulula: ungafunda ukuyisebenzisa ngaphakathi kwemizuzu eminingana.

- Ukuqalisa okusheshayo: kungaqalwa ukwenza umsebenzi wokushisa ngaphansi kombandela wokuthi amanzi namandla kagesi ayatholakala.

- Okuphansi amandla ukusetshenziswa: Njengoba kuqhathaniswa ne-vacuum tube evamile imishini yamandla aphezulu, ingonga amandla cishe ngama-70%. Okuncane ngosayizi wocezu lomsebenzi ukuthi, ukusetshenziswa kwamandla okuphansi kungaba njalo.

- Ukusebenza okuphezulu:inezici ezinjengokushisa okufanayo (kusebenza ukulungisa izikhala zekhoyili yokungeniswa ukuqinisekisa ukushisa okufanelekile njengoba kudingwa yingxenye ngayinye yomsebenzi), ukufudumala okusheshayo nokulinganiselwa kwe-oxic horizon, futhi kungavikela kunoma iyiphi imfucuza ngemuva kokufakwa.

- Ukuvikelwa okuphelele:inemisebenzi efana nokucindezelwa ngokweqile, ukwedlula isikhathi samanje, ukushisa okukhulu kanye nezinkomba zokushoda kwamanzi kanye nokulawula nokuvikela okuzenzakalelayo.

- Izinga lokushisa elilawulwayo: kusebenza ukulawula ukushisa kokushisa izingcezu zomsebenzi ngokwesikhathi sokushisa esethwe ngaphambilini, futhi ngaleyo ndlela ulawule ukushisa kokushisa endaweni ethile yobuchwepheshe.

- Ukuhlanganiswa okuphelele kokulayisha okuphelele: ingasebenza ngokuqhubekayo amahora angama-24.

- Usayizi omncane nesisindo esincane: inesisindo samakhilogremu ambalwa kuphela, lapho, isikhala esilinganiselwe sendawo singagcina ngempumelelo indawo yokusebenzela.

- Ukuqedwa kwamandla aphezulu: ayidingi sinyathelo senyuka esingaveza ugesi ongaba yizinkulungwane eziyishumi, futhi ngaleyo ndlela ingaqinisekisa ukuphepha okuphezulu.