ISIBUSE SOKUHAMBISA ELECTRIC

Incazelo

ISIBUSE SOKUHAMBISA ELECTRIC

Isithando somlilo sokungenisa ugesi siwuhlobo lwesithando somlilo esincibilika esisebenzisa imisinga kagesi ukuncibilikisa insimbi. Izithando zokungeniswa zilungele ukuncibilika kanye nokuhlanganisa izinhlobonhlobo zezinsimbi ezinokulahlekelwa okuncane kokuncibilika, noma kunjalo, ukucwengwa okuncane kwensimbi kungenzeka.

ISIMISO SESITHANDA SOKUSHISA

Umgomo wesithando somlilo sokungeniswa ukushisa kwe-induction.

UKUSHISA KWE-INDUCTION: Ukushisa kwe-induction kuyindlela yokushisa okungathintekiyo yezinto ezisebenzayo.

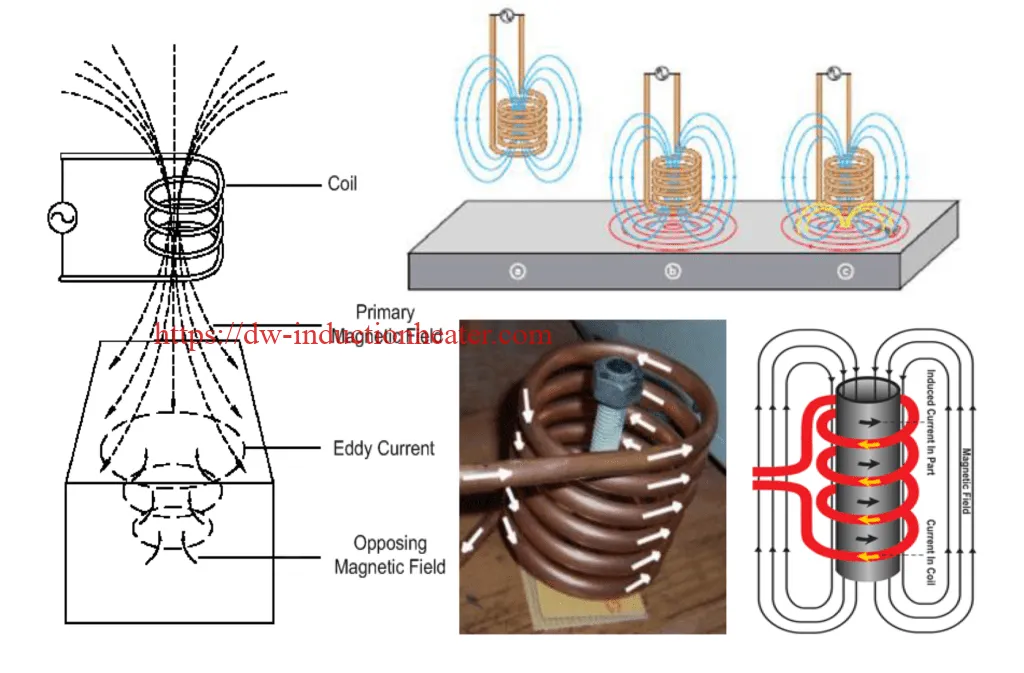

Umgomo wokushisa okufakwayo usekelwe ikakhulukazi ezintweni ezimbili ezaziwayo ezibonakalayo:

1. Ukungeniswa kwe-Electromagnetic

2. Umphumela we-Joule

1) ELECTROMAGNETIC INDUCTION

Ukudluliswa kwamandla entweni ezoshiselwa kwenzeka ngokungeniswa kwe-electromagnetic.

Noma iyiphi into esebenza ngogesi ebekwe endaweni kazibuthe eguquguqukayo iyindawo yamaza kagesi, okuthiwa ama-eddy currents, azogcina eholele ekushiseni kwe-joule.

2) JOULE UKUSHISA

Ukushisa kwe-Joule, okubuye kwaziwe ngokuthi ukufudumeza kwe-ohmic nokufudumeza okuphikisayo, inqubo lapho ukudlula kwamandla kagesi ku-conductor kukhipha ukushisa.

Ukushisa okukhiqizwayo kuhambisana nesikwele samanje esiphindwe ukumelana nogesi kocingo.

Ukushisisa okungeniswayo kuncike ezicini ezihlukile zamandla efrikhwensi yomsakazo (RF) - leyo ngxenye ye-electromagnetic spectrum engaphansi kwe-infrared namandla e-microwave.

Njengoba ukushisa kudluliselwa emkhiqizweni ngamagagasi kagesi, ingxenye ayikaze ihlangane ngokuqondile nanoma yiliphi ilangabi, i-inductor ngokwayo ayishisi futhi akukho ukungcoliswa komkhiqizo.

-I-induction ukushisa ukushisa okusheshayo, okuhlanzekile, okungangcolisi.

-Ikhoyili ye-induction ipholile uma uyithinta; ukushisa okwakhiwa kukhoyili kuhlala kupholiswa ngamanzi ajikelezayo.

IZIPHUMA ZE ISIBUSE SOKUHAMBISA ELECTRIC

— Isithando somlilo sikagesi sidinga ikhoyili kagesi ukukhiqiza ukushaja. Le khoyili yokushisisa igcina ishintshiwe.

-I-crucible lapho insimbi ibekwe khona yenziwe ngezinto ezinamandla ezingakwazi ukumelana nokushisa okudingekayo, futhi ikhoyili kagesi ngokwayo ipholiswe uhlelo lwamanzi ukuze ingashisi noma incibilike.

- Isithando somlilo singahluka ngosayizi, kusukela esithandweni somlilo esincane esisetshenziselwa ama-alloys anembe kakhulu kuphela ngesisindo esingangekhilogremu kuya eziko ezinkudlwana ezenziwe ukukhiqiza insimbi ehlanzekile yezinhlelo eziningi ezahlukene.

-Inzuzo yesithando somlilo sokungeniswa yinqubo yokuncibilika ehlanzekile, eyonga amandla futhi elawuleka kahle uma kuqhathaniswa nezinye izindlela eziningi zokuncibilika kwensimbi.

-ama-foundries asebenzisa lolu hlobo lwesithando somlilo futhi manje nezinye izisekelo zensimbi ezengeziwe sezishintsha ama-cupolas ngeziko lokungeniswa ukuze zincibilikise insimbi esakazwayo, njengoba eyangaphambili ikhipha uthuli oluningi nokunye ukungcola.

— Amandla okushisa okungena ngogesi asukela ngaphansi kwekhilogremu eyodwa kuya kumthamo wamathani ayikhulu, futhi asetshenziselwa ukuncibilikisa insimbi nensimbi, ithusi, i-aluminium, nezinsimbi eziyigugu.

-Into eyodwa enkulu ebuyisela emuva ekusetshenzisweni kwesithando somlilo endaweni eyisisekelo ukuntuleka komthamo wokucwenga; izinto zokushaja kufanele zihlanzeke emikhiqizweni ye-oxidation kanye nokwakheka okwaziwayo, futhi ezinye izakhi ze-alloying zingalahleka ngenxa ye-oxidation (futhi kufanele zengezwe kabusha ekuncibilikeni).

UBUHLE BESITHANDA SOKUSHINISA KAgesi:

Izithando zokungenisa ugesi zikagesi zinikeza izinzuzo ezithile ngaphezu kwezinye izinhlelo zesithando somlilo. Zihlanganisa:

Isivuno Esiphakeme. Ukungabikho kwemithombo evuthayo kunciphisa ukulahlekelwa kwe-oxidation okungaba okubalulekile kwezomnotho zokukhiqiza.

Ukuqala Ngokushesha. Amandla agcwele avela kugesi ayatholakala, ngokushesha, ngaleyo ndlela anciphisa isikhathi sokufinyelela izinga lokushisa lokusebenza. Izikhathi ezibandayo zokushaja ukuze uthephe zehora elilodwa kuya kwamabili zivamile.

Ukuvumelana nezimo. Ayikho insimbi encibilikisiwe edingekayo ukuze kuqalwe umshini wokuncibilikisa we-medium frequency coreless induction. Lokhu kusiza ukuqala okubandayo okuphindaphindiwe kanye nezinguquko ezivamile ze-alloy.

Ukugqugquzela Kwemvelo. Amayunithi efrikhwensi emaphakathi anganikeza isenzo esinamandla esinyakazayo esiholela ekuncibilikeni okulinganayo.

Ukuncibilika kokuhlanza. Ayikho imikhiqizo ephuma kumlilo isho indawo encibilikayo ehlanzekile futhi ayikho imikhiqizo ehlobene nezinhlelo zokulawula ukungcoliswa komlilo.

Ukufakwa Okuhlangene. Amazinga aphezulu okuncibilika angatholakala ezithandweni ezincane.

I-Refractory Encishisiwe. Usayizi ohlangene maqondana nezinga lokuncibilika usho ukuthi iziko elifakwayo lidinga ukugoba kancane kunamayunithi aphehla uphethiloli Indawo Yokusebenza Engcono. Iziko lokungeniswa zithule kakhulu kuneziko legesi, ama-arc furnaces, noma ama-cupolas. Ayikho igesi evuthayo ekhona futhi ukushisa kwemfucuza kuncishisiwe.

Ukonga Amandla. Sekukonke ukusebenza kahle kwamandla ekuncibilikeni kokungeniswa kusukela kumaphesenti angama-55 kuye kwangama-75, futhi kungcono kakhulu kunezinqubo zokuvutha.