ukushisa ukushisa ukushisa okushisayo

Incazelo

Ukushisa ukushisa ukushisa okushisayo ne-IGBT yokufakelwa kokushisa uhlelo

Inhloso Ukushisa umjikelezo wamadiski egeja ngaphambi kwenqubo eshisayo (ecijayo)

Izindwangu zensimbi ye-Flat Boron yensimbi, OD 460 kuya ku-710 mm (18 kuye ku-28 ”) ubukhulu 3.2 kuya ku-10 mm (8/64 kuya ku-25/64”)

Ukushisa 725 ° C 1335 ° F

I-Frequency 75 kHz

Izinsiza ze-DW-HF-120 kW uhlelo lokushisa lokungeniswa lusebenzisa amakhanda womsebenzi we-2, uhlelo lokushintsha, ama-4 coil aklanywe ngokukhethekile, uhlelo lwe-chiller

Inqubo Ohlelweni lwe-PLC, umshini ngamunye emigudlwini emibili unenhloko yokusebenza ekude futhi inepulatifomu ejikelezayo lapho i-disc ibanjwa khona ngokuvundlile futhi ibanjwe ngesimo yi-central nonmagnetic

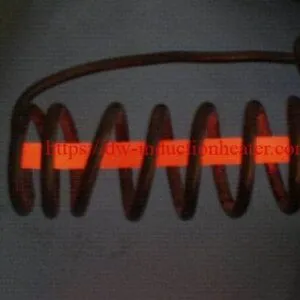

ipuleti elingu-100 mm lingaphansi kobubanzi be-disc. Ikhoyili yokushisa engama-250 mm (10 ”) ibekwe phezu kwensimbi, ijikeleza ngaphambi kwamaroli wengcindezi. Lokhu kushisa wonke umphetho wediski.

Ngemuva kwemizuzwana embalwa yokushisa, umphetho ufinyelela izinga lokushisa elidingekayo futhi i-disc yenziwa ukuba ivule ngo-30 rpm. Ingcindezi ivalwa, yakha iphrofayili ebukhali. Umngcele wokugcina utholakala ngemuva kokushintshana kabili kwediski.

Imiphumela / Izinzuzo Ukushisa kwe-Induction kunikeza inqubo eshesha kakhulu uma kuqhathaniswa nokugoqa okubandayo; iphrofayili oyifunayo itholakala ngemuva kwemizuzwana embalwa, uma iqhathaniswa nemizuzu embalwa. Ikhwalithi ye-metallurgical yomphetho ophelile iphezulu, ngoba inqubo iyenza lukhuni indaba.

Okokusebenza nenqubo kubolekisa i-automation ye-robotic