Umshini Wokushisela Umthungo Nepayipi Nge-Induction heater

Incazelo

I-Induction Seam Welding Machine Ye-Welding Tube kanye ne-Pipe Solutions

Kuyini ukukhishwa kwe-induction?

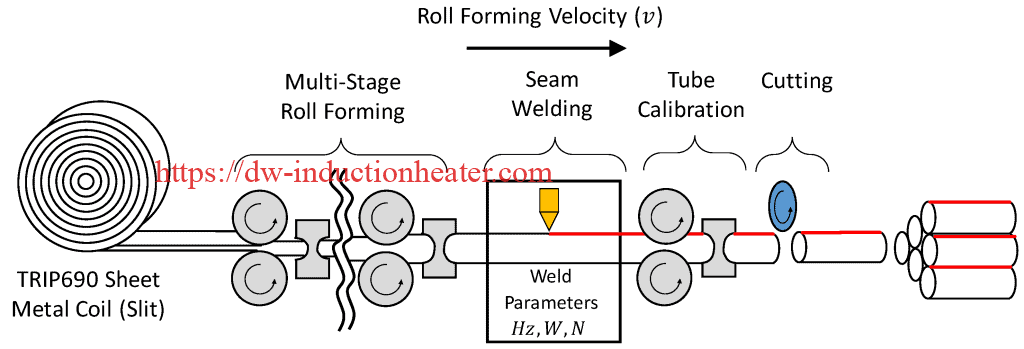

Nge-induction welding, ukushisa kudonswa ngozibuthe endaweni yokusebenza. Ijubane nokunemba kwe-induction welding kuyenza ilungele ukushisela onqenqemeni kwamashubhu namapayipi. Kule nqubo, amapayipi adlula ikhoyili yokungeniswa ngesivinini esikhulu. Njengoba benza kanjalo, imiphetho yabo iyafudumala, bese iyampintshana ukuze yenze umthungo we-weld we-longitudinal. I-induction welding ifaneleka ikakhulukazi ukukhiqizwa kwevolumu ephezulu. Ama-welders e-induction angabuye afakwe amakhanda okuxhumana, awaguqule abe izinhlelo ezimbili zokushisela.

Nge-induction welding, ukushisa kudonswa ngozibuthe endaweni yokusebenza. Ijubane nokunemba kwe-induction welding kuyenza ilungele ukushisela onqenqemeni kwamashubhu namapayipi. Kule nqubo, amapayipi adlula ikhoyili yokungeniswa ngesivinini esikhulu. Njengoba benza kanjalo, imiphetho yabo iyafudumala, bese iyampintshana ukuze yenze umthungo we-weld we-longitudinal. I-induction welding ifaneleka ikakhulukazi ukukhiqizwa kwevolumu ephezulu. Ama-welders e-induction angabuye afakwe amakhanda okuxhumana, awaguqule abe izinhlelo ezimbili zokushisela.

Yiziphi izinzuzo ze-induction Seam welding?

I-automated induction longitudinal welding iyinqubo ethembekile, ehamba phambili. Ukusetshenziswa kwamandla okuphansi nokusebenza kahle okuphezulu kwe I-HLQ Induction welding systems ukunciphisa izindleko. Ukulawuleka kwazo nokuphindaphindeka kunciphisa izinsalela. Amasistimu ethu nawo ayavumelana nezimo—ukufanisa umthwalo okuzenzakalelayo kuqinisekisa amandla aphelele aphumayo kunhlobonhlobo yamasayizi wamashubhu. Futhi izinyathelo zabo ezincane zibenza kube lula ukuhlanganisa noma ukubuyisela emigqeni yokukhiqiza.

I-automated induction longitudinal welding iyinqubo ethembekile, ehamba phambili. Ukusetshenziswa kwamandla okuphansi nokusebenza kahle okuphezulu kwe I-HLQ Induction welding systems ukunciphisa izindleko. Ukulawuleka kwazo nokuphindaphindeka kunciphisa izinsalela. Amasistimu ethu nawo ayavumelana nezimo—ukufanisa umthwalo okuzenzakalelayo kuqinisekisa amandla aphelele aphumayo kunhlobonhlobo yamasayizi wamashubhu. Futhi izinyathelo zabo ezincane zibenza kube lula ukuhlanganisa noma ukubuyisela emigqeni yokukhiqiza.

Isetshenziswa kuphi i-induction seam welding?

I-induction welding isetshenziswa embonini ye-tube kanye nepayipi ye-longitudinal welding yensimbi engagqwali (magnetic and non-magnetic), i-aluminium, i-low-carbon kanye ne-high-strength low-alloy (HSLA) izinsimbi nezinye izinto eziningi zokuqhuba.

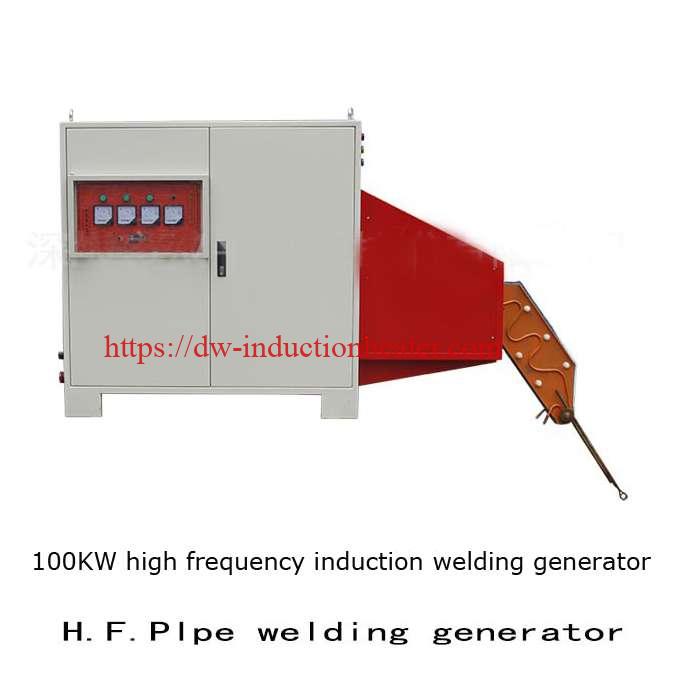

I-High Frequency Induction Seam Welder

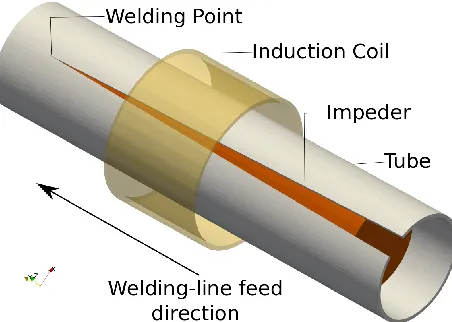

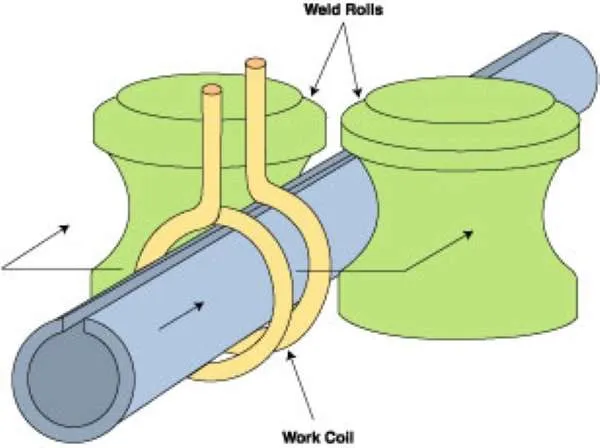

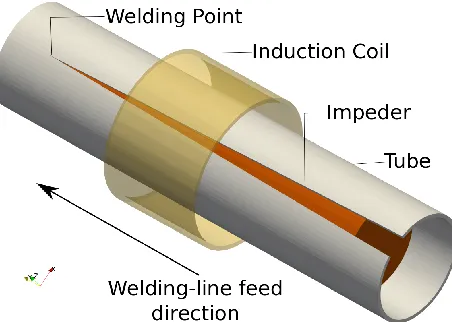

Enqubweni ye-high frequency induction tube welding, i-high frequency current ifakwa kuthubhu ye-seam evulekile ngekhoyili ye-induction etholakala ngaphambi (phezulu ukusuka) endaweni ye-weld, njengoba kuboniswe ku-Fig. 1-1. Amaphethelo eshubhu ahlukaniswa ngokwehlukana lapho edlula kukhoyili, enze i-vee evulekile lapho i-apex yayo ingaphambi kancane kwephoyinti lokushisela. Ikhoyili ayixhumani neshubhu.

Ikhoyili isebenza njengesisekelo se-high frequency transformer, futhi ithubhu lomthungo elivulekile lisebenza njenge-turn-turn yesibili. Njengokwezinhlelo zokusebenza zokushisa zokungeniswa okujwayelekile, indlela yamanje eyenziwe endaweni yokusebenza ijwayele ukuhambisana nokuma kwekhoyili yokungeniswa. Iningi lamandla akhona liqeda indlela yalo ezungeza umucu owenziwe ngokugeleza emaphethelweni futhi liminyene lizungeze umkhawulo wokuvuleka okumise okwe-vee emgqeni.

Ukuminyana kwamanje kwefrikhwensi ephezulu kuphezulu emaphethelweni aseduze ne-apex kanye naku-apex uqobo. Ukushisisa okusheshayo kwenzeka, okwenza ukuthi imiphetho ibe kuzinga lokushisa lokushisela lapho ifika phezulu. I-pressure rolls iphoqa imiphetho eshisayo ndawonye, iqedela ukushisela.

Imvamisa ephezulu ye-welding current enesibopho sokushisa okugxilile emaphethelweni e-vee. Inenye inzuzo, okungukuthi ingxenye encane kuphela yengqikithi yamanje ethola indlela yayo eduze nomugqa owenziwe. Ngaphandle uma ububanzi beshubhu buncane kakhulu uma buqhathaniswa nobude be-vee, yamanje ikhetha indlela ewusizo emaphethelweni eshubhu elenza i-vee.

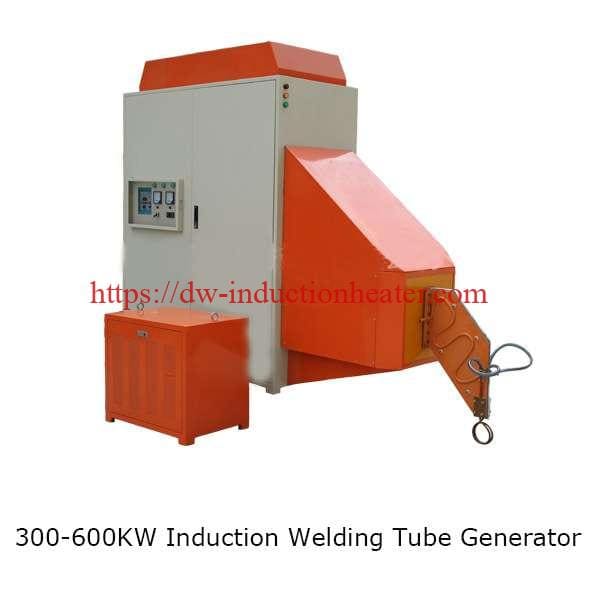

Umkhiqizo: Umshini Wokushisela Umthungo Wokungeniswa

| Umshini Wokushisela Wonke I-Solid State (MOSFET) Umshini Wokushisela Umthungo We-High Frequency Induction For Tube kanye Nepayipi | ||||||

| imodeli | GPWP-60 | GPWP-100 | GPWP-150 | GPWP-200 | GPWP-250 | GPWP-300 |

| amandla wokufaka | 60KW | 100KW | 150KW | 200KW | 250KW | 300KW |

| voltage Input | 3Izigaba, 380/400/480V | |||||

| DC Voltage | 0-250V | |||||

| DC yamanje | 0-300A | 0-500A | 800A | 1000A | 1250A | 1500A |

| imvamisa | I-200-500KHz | |||||

| Ukusebenza kahle komphumela | 85% -95% | |||||

| Isici samandla | Umthwalo ogcwele <0.88 | |||||

| Ukupholisa Umfutho Wamanzi | >0.3MPa | |||||

| Ukupholisa Ukugeleza Kwamanzi | >60L/min | >83L/min | >114L/min | >114L/min | >160L/min | >160L/min |

| Itlet lokushisa lamanzi | <35 ° C | |||||

Ukulungiswa kwamandla we-IGBT wesifunda sonke esiqinile kanye nobuchwepheshe bokulawula bamanje obuguquguqukayo, kusetshenziswa okuhlukile kwe-IGBT okushintshwa okuthambile kokunqunywa kwe-high-frequency kanye nokuhlunga kwe-amorphous ukulawula amandla, ukulawulwa kwe-inverter ye-IGBT enesivinini esikhulu nokunembayo, ukuze kuzuzwe u-100-800KHZ/ 3 -300KW umkhiqizo isicelo.

- Ama-capacitor anamandla amakhulu angenisiwe asetshenziselwa ukuthola imvamisa ye-resonant ezinzile, ukuthuthukisa ngempumelelo ikhwalithi yomkhiqizo, nokubona ukuzinza kwenqubo yamapayipi ashiselwe.

- Faka esikhundleni ubuchwepheshe bokulungisa amandla e-thyristor obujwayelekile ngobuchwepheshe bokulungisa amandla okusika ama-high-frequency ukuze ufinyelele ukulawulwa kwezinga le-microsecond, uqaphele kakhulu ukulungiswa okusheshayo nokuzinza kokuphuma kwamandla enqubo yepayipi lokushisela, ukuphuma kwe-ripple kuncane kakhulu, kanye ne-oscillation yamanje ezinzile. Ukushelela nokuqondile kwe-weld seam kuqinisekisiwe.

- Ezokuphepha. Ayikho imvamisa ephezulu kanye ne-voltage ephezulu ye-volts engu-10,000 kumishini, engagwema ngokuphumelelayo imisebe, ukuphazamiseka, ukukhishwa, ukuthungela nezinye izenzakalo.

- Inekhono eliqinile lokumelana nokuguquguquka kwamandla kagesi wenethiwekhi.

- Inesici samandla aphezulu kulo lonke uhla lwamandla, olungasindisa ngempumelelo amandla.

- Ukusebenza kahle okuphezulu nokonga amandla. Imishini isebenzisa ubuchwepheshe bokushintshwa okuthambile obunamandla amakhulu ukusuka kokokufaka kuye kokukhiphayo, okunciphisa ukulahleka kwamandla futhi ithole ukusebenza kahle kukagesi okuphakeme kakhulu, futhi inamandla aphezulu kakhulu ebangeni lamandla aphelele, ewonga ngempumelelo amandla, ahluke kwendabuko Uma kuqhathaniswa neshubhu. thayipha imvamisa ephezulu, ingasindisa u-30-40% womphumela wokonga amandla.

- Imishini i-miniaturized futhi ihlanganiswe, okusindisa kakhulu indawo ehlala kuyo. Izinto zokusebenza azidingi isiguquli esisuka phansi, futhi asidingi i-inductance enkulu yokuvama kwamandla ukuze kulungiswe i-SCR. Isakhiwo esincane esihlanganisiwe siletha lula ukufakwa, ukulungiswa, ukuthutha, nokulungiswa.

- Ibanga lemvamisa lika-200-500KHZ libona ukushiselwa kwamapayipi ensimbi nensimbi engagqwali.

I-HLQ Induction inohlu olubanzi kakhulu lwezixazululo zemboni yamashubhu namapayipi. I-HLQ Induction Seam Welder iyisixazululo esifakazelwe sokushisela insimbi engagqwali, i-aluminium, insimbi enekhabhoni ephansi nensimbi enamandla amakhulu futhi kungenzeka iwumshini wokushisela ongcono kakhulu emhlabeni.

Okukhiphayo okwengeziwe: Ukufaniswa komthwalo we-elekthronikhi okuqhubekayo kuvikela amandla aphelele okukhiphayo kuhlu olubanzi lwamasayizi amashubhu.

Isikhathi esengeziwe: Ubufakazi bomjikelezo omfushane, ukusebenza okuphephile nokuthembekile.

Ukusebenza kahle okungenakuqhathaniswa: Isilungisi se-Diode esinamandla angashintshi angu-0.95 kuwo wonke amazinga wamandla, kanye nesici sokusebenza kahle esingu-85-87%.

I-Eco kanye ne-energy friendly: Ukusebenza kahle okuphezulu konga amandla futhi kunciphisa ukusetshenziswa kwamanzi okupholisa.

Kulula ukuyisebenzisa: Iphaneli yokulawula okulula ukulisebenzisa enezilungiselelo ezincane zezandla yenza i-Induction Seam Welder ibe lula kakhulu ukusebenza.

Ububanzi obubanzi bamandla: Ukusuka ku-40 kW ukuya ku-1000 kW. Ibanga lefrikhwensi lika-200-500 kHz. Idizayini yemoduli yesimanje: Indawo encane, ehlangene yonga indawo ebalulekile yaphansi futhi yenza ukuhlanganisa komugqa kube lula. Ifinyelela ku-1000 kW etholakala kwikhambi lekhabhinethi elilodwa.

Ububanzi obubanzi bamandla: Ukusuka ku-40 kW ukuya ku-1000 kW. Ibanga lefrikhwensi lika-200-500 kHz. Idizayini yemoduli yesimanje: Indawo encane, ehlangene yonga indawo ebalulekile yaphansi futhi yenza ukuhlanganisa komugqa kube lula. Ifinyelela ku-1000 kW etholakala kwikhambi lekhabhinethi elilodwa.

Uhlelo oluphelele: Ihlanganisa isilungisi se-diode, amamojula okuguqula izinto, isigaba sokuphumayo, ibha yebhasi kanye nohlelo lokulawula opharetha.

Iwaranti engenakuqhathaniswa: iwaranti yeminyaka emithathu kumamojula we-HLQ Induction Seam Welder namakhadi omshayeli.

Uhla olugcwele lwezinto ezisetshenziswayo: Amakhoyili, ama-ferrite, ama-impeder kanye nemishini yokuvala amashubhu.