Amakhoyili wokushisa wokungenisa ziwuhlobo lwezinto zokufudumeza ezivame ukusetshenziswa ezinhlelweni zokushisisa zokungeniswa. Lawa makhoyili ngokuvamile enziwa ngethusi noma ngezinye izinto ezisetshenziswayo futhi adizayinelwe ukukhiqiza inkambu kazibuthe eshintshanayo lapho umsinga kagesi oshintshanayo udlula kuwo. Indawo kazibuthe eshintshanayo idala ama-eddy currents entweni eshiselwayo, iyenze ishise ngokushesha. Amakhoyili okushisa okufakwayo asetshenziswa kakhulu ezinhlelweni ezihlukene zezimboni ezifana nokusebenza kwensimbi, ukwelapha ukushisa, kanye ne-soldering, njengoba enikeza ukufudumeza okusheshayo nokuphumelelayo ngokulawula izinga lokushisa okunembile.

Ezweni lanamuhla elisheshayo, izimboni zihlala zifuna izindlela ezintsha nezisebenzayo zokuthuthukisa izinqubo zazo zokukhiqiza. Enye yentuthuko enjalo yobuchwepheshe eye yashintsha ubuchwepheshe bokwelapha ukushisa ikhoyili yokushisisa. Amakhoyili okushisa e-induction asetshenziswa kakhulu ezimbonini ezihlukahlukene, kuhlanganise nezimoto, i-aerospace, i-electronics, kanye neyokukhiqiza, ngenxa yekhono labo lokukhiqiza ukushisa ngokushesha nangokunembile. Lesi sihloko sihlose ukuhlola izimiso zokusebenza, izinhlelo zokusebenza, izinzuzo, kanye namathemba esikhathi esizayo amakhoyili okushisa angeniswayo.

1. Izimiso Zokusebenza zamakhoyili Okushisa Okufakwayo

Amakhoyili okushisa e-induction asebenza ngomgomo wokungeniswa kwe-electromagnetic. Inqubo ihilela ukudlulisa i-alternating current (AC) ikhoyili, ekhiqiza inkambu kazibuthe. Uma i-conductive material ibekwe ngaphakathi kwale nkambu kazibuthe, ama-eddy currents ayangeniswa kulokho. Lawa ma-eddy currents akhiqiza ukushisa ngenxa yokumelana kwezinto. Ukushisa okukhiqizwayo kungalawulwa ngokulungisa imvamisa namandla wamanje oshintshanayo.

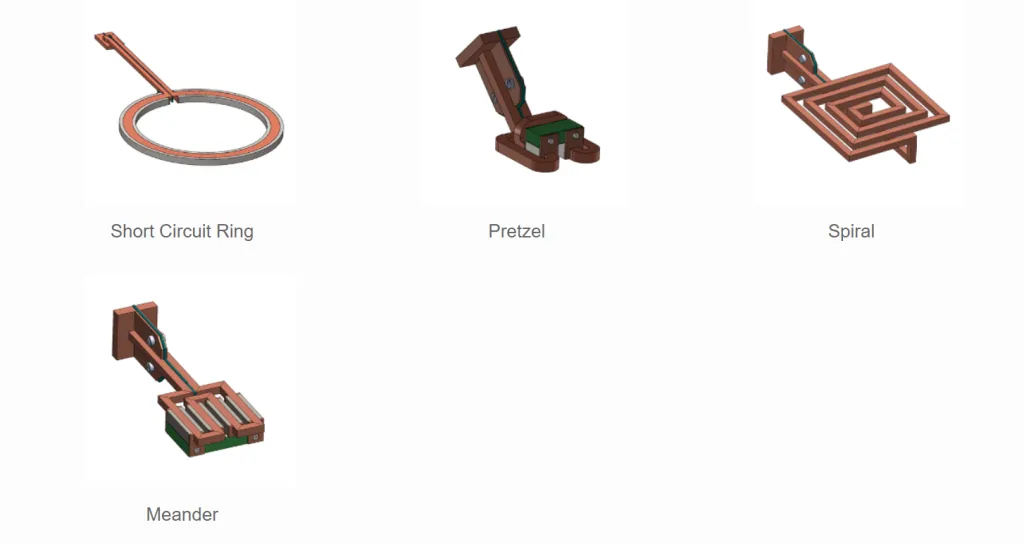

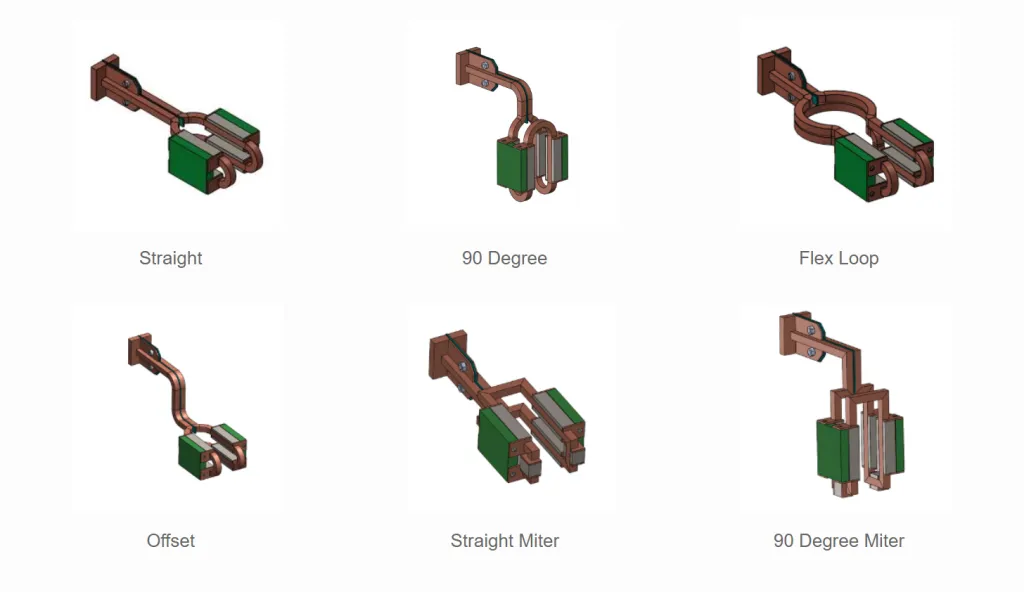

2. Izinhlobo zamakhoyili okushisa okufakwayo

Kunezinhlobo ezimbalwa zamakhoyili okushisa okufakwayo atholakalayo, ngayinye yakhelwe izinhlelo ezithile. Ezinye izinhlobo ezijwayelekile zihlanganisa:

2.1. I-Helical Heating Coils

Amakhoyili angama-Helical aqukethe inxeba elilodwa locingo olusesimweni se-helix. Zifanele ukushisa izinto ze-cylindrical, njengamapayipi noma izinduku, njengoba i-helical shape ivumela ukushisa okufanayo ngobude bento.

2.2. Amakhoyili ePancake

Amakhoyili epancake, awaziwa nangokuthi amakhoyili ayisicaba, angamakhoyili ayisicaba, ayindilinga alungele ukushisisa izinto eziyisicaba noma ezimise ngendlela engavamile. Banikeza inkambu kazibuthe egxilile, eqinisekisa ukufudumeza okusebenzayo nokwasendaweni.

2.3. Amakhoyili angama-Cylindrical

Amakhoyili angama-cylindrical aklanyelwe ukufudumeza izinto ezinkulu, eziyi-cylindrical, njengemiphongolo noma amathangi. Ngokuvamile zenziwe ngokuphenduka okuphindaphindiwe kwezintambo zocingo ezizungeze isilinda, okunikeza inkambu kazibuthe efanayo yokushisisa.

2.4. Amakhoyili Wokungeniswa Wokuqina

Amakhoyili okungenisa ukuze aqiniswe amakhoyili akhethekile asetshenziswa kunqubo yokwelapha ukushisa eyaziwa ngokuthi ukuqina kokungeniswa. Lawa makhoyili aklanyelwe ukuzuza ukushisisa okusheshayo nokunembayo kwezindawo ezithile zengxenye yensimbi, okuholela ekwandeni kokuqina nokumelana nokugqoka.

2.5 Amakhoyili emfoloko

Amakhoyili emfologo anemfoloko emibili imishini ezisetshenziselwa ukushisisa izinhlangothi ezimbili eziphikisanayo zocwecwe lokusebenza. Zivame ukusetshenziselwa izinhlelo zokusebenza ze-brazing.

3. Izicelo zamaKhoyili Okushisa Okufakwayo

3. Izicelo zamaKhoyili Okushisa Okufakwayo

3.1. Ukuqina kwendawo

Enye yezinhlelo zokusebenza eziyinhloko zamakhoyili okushisa okufakwayo ukuqina kwendawo. Ukushisisa okwasendaweni okunikezwa yilawa makhoyili kuvumela ukulawula okunembile kwenqubo yokuqina, okuholela ekuthuthukisweni kokungagugi nokuqina kwezingxenye ezifana namagiya, shafts, nama-bearings.

3.2. I-Brazing kanye ne-Soldering

Amakhoyili okushisa e-induction asetshenziswa kakhulu ekubhrezeni nasekufakweni kwe-soldering. Ukushisisa okusheshayo nokwasendaweni okunikezwa yila makhoyili kwenza kuhlanganiswe kahle izingxenye zensimbi ezihlukahlukene, okuhlanganisa amapayipi, izintambo, nezingxenye ze-electronic.

3.3. I-Anealing kanye Nokunciphisa Ukucindezeleka

Amakhoyili wokushisisa ongeniswa nawo asetshenziselwa izinqubo zokuqeda ingcindezi. Lezi zinqubo zihlanganisa ukushisisa izingxenye zensimbi ezingeni lokushisa elithile bese zizipholisa kancane kancane. Amakhoyili okushisa angeniswayo anikeza ukufudumeza okunembile nokulawulwayo, okuqinisekisa ukufana kuyo yonke ingxenye.

3.4. I-Shrink Fitting

I-Shrink fitting yinqubo ehlanganisa ukushisisa ingxenye yensimbi ukuze iyinwebe, okuvumela ukuhlangana kalula nenye ingxenye. Amakhoyili okushisa angeniswayo ahlinzeka ngokufudumeza okusheshayo nasendaweni, okuwenza alungele ukuncipha kokufaka izicelo ezimbonini ezifana nezezimoto nezokukhiqiza.

3.5. Ukuncibilika kanye Ukusakaza

Amakhoyili okushisa e-induction avame ukusetshenziselwa ukuncibilikisa nokuphonsa izinsimbi. Ukushisisa kwe-high-frequency okunikezwa yila makhoyili kuvumela ukuncibilika okuphumelelayo nokulawulwayo kwezinsimbi ezihlukahlukene, okuhlanganisa insimbi, i-aluminium, nethusi.

4. Izinzuzo ze-Induction Heating Coils

4.1. Ukusebenza kahle nokonga Amandla

Amakhoyili okushisa angeniswayo anikeza amandla aphezulu ngenxa yekhono lawo lokukhiqiza ukushisa ngokuqondile ngaphakathi kwezinto ezishiswayo. Lokhu kuqeda isidingo sokushisisa futhi kunciphisa ukulahlekelwa ukushisa, okuholela ekongeni kwamandla okubalulekile.

4.2. Ukushisisa Okusheshayo

Amakhoyili okushisa angeniswayo ahlinzeka ngokufudumeza ngokushesha, okuvumela izikhathi ezimfishane zenqubo kanye nokwanda kokukhiqiza. Lokhu kunenzuzo ikakhulukazi ezimbonini lapho isikhathi siyisici esibalulekile, njengokukhiqiza izimoto kanye nogesi.

4.3. Ukushisisa Okunembile Nokulawulwayo

Amakhoyili okushisa angeniswayo anikeza ukufudumeza okunembile nokulawulwayo, okwenza abakhiqizi bakwazi ukuthola imiphumela engaguquki nefanayo. Ikhono lokulungisa amandla kanye nemvamisa ye-alternating current ivumela ukulawula izinga lokushisa okunembile, ukuqinisekisa umphumela wokwelashwa okushisa odingekayo.

4.4. Ukuphepha kanye Nemvelo

Amakhoyili okushisa angeniswayo ayisixazululo esiphephile nesihambisana nemvelo. Njengoba ukushisa kukhiqizwa ngokuqondile ngaphakathi kwento eshisisayo, alikho ilangabi elivulekile noma indawo eshisayo, okunciphisa ubungozi bezingozi. Ukwengeza, amakhoyili okushisa angeniswayo awakhiqizi igesi eyingozi noma imfucuza, okuwenza abe yisinqumo esimeme.

5. Amathemba Nezinto Ezintsha Ezizayo

Umkhakha wamakhoyili wokushisisa ongeniswayo uyaqhubeka nokuvela, ngocwaningo oluqhubekayo nokuthuthukiswa okugxile ekuthuthukiseni ukusebenza kwawo kanye nokwandisa izinhlelo zabo zokusebenza. Amanye amathemba esikhathi esizayo nezinto ezintsha zihlanganisa:

5.1. Ukuhlanganiswa ne-Industry 4.0 Technologies

Ukuhlanganiswa kwamakhoyili wokushisisa ongeniswayo nobuchwepheshe be-Industrial 4.0, njengobuhlakani bokwenziwa kanye ne-inthanethi Yezinto (IoT), kunamandla amakhulu. Lokhu kuhlanganiswa kungavumela ukuqapha kwesikhathi sangempela nokulawula inqubo yokushisisa, ukuthuthukisa ukusebenza kahle nokukhiqiza.

5.2. Intuthuko ku-Coil Design

Intuthuko ekwakhiweni kwamakhoyili, njengokusetshenziswa kwezinto ezithuthukisiwe namajiyometri, ingathuthukisa ukusebenza kahle kanye nokusebenza kwamakhoyili okushisa angeniswayo. Lokhu kuthuthuka kungaholela ekusabalaliseni ukushisa okuthuthukisiwe, ukunciphisa ukusetshenziswa kwamandla, kanye nokuqina okukhuphukile.

5.3. Ukuthuthukiswa Kwezindlela Ezintsha Zokushisisa

Abacwaningi basaqhubeka behlola izindlela ezintsha zokushisisa besebenzisa amakhoyili okushisa angeniswayo. Amasu afana nokushisisa okukhethekile, lapho izindawo ezithile zengxenye zishiselwa khona, futhi ukushisisa kanyekanye kwezingxenye eziningi kuyafundelwa ukuze kusetshenziswe amandla azo ezimbonini ezihlukahlukene.

Isiphetho

Amakhoyili wokushisa wokungenisa zenze izinguquko kubuchwepheshe bokwelapha ukushisa, zinikeza izixazululo zokushisisa ezisebenza kahle, ezinembayo nezilawulwayo. Ukusetshenziswa kwabo ekuqiniseni indawo, ukubhula, ukuhlanganisa, nezinye izinqubo eziningi kuthuthukise kakhulu izinqubo zokukhiqiza kuzo zonke izimboni ezihlukahlukene. Ngokuthuthuka okuqhubekayo kanye nezinqubo ezintsha, ikusasa lamakhoyili okushisa angeniswayo libukeka lithembisa, ngokuhlangana okungenzeka nobuchwepheshe be-Industrial 4.0 kanye nokuthuthukiswa kwamasu amasha okufudumeza. Njengoba izimboni ziqhubeka nokulwela ukukhiqiza okuthuthukisiwe nokusimama, amakhoyili wokushisisa ngokungangabazeki azodlala indima ebalulekile ekuhlangabezaneni nale migomo.