Isingeniso Se-Induction Harding and Tempering

Iyini i-Induction Hardening?

Ukuqeda ukuqina inqubo yokwelapha ukushisa esetshenziselwa ukukhetha ngokukhetha ukuqina kwezingxenye zensimbi, njengezintambo zenduku, kuyilapho kugcinwa umgogodla oqinile futhi odonsayo. Le nqubo ihlanganisa ukushisisa ingaphezulu lensimbi kusetshenziswa i-high-frequency alternating current (AC) bese iyicisha ngokushesha ukuze kuzuzwe indawo eqinile, engagugi.

Yini i-Tempering?

I-Tempering inqubo yokwelapha ukushisa elandela ukuqina. Kubandakanya ukushisisa kabusha insimbi eqinile iye ezingeni lokushisa elithile ngaphansi kwephuzu elibalulekile bese uyivumela ukuthi iphole kancane. I-Tempering ithuthukisa ukuqina, i-ductility, kanye nokumelana nomthelela wensimbi ngokukhulula izingcindezi zangaphakathi kanye nokunciphisa ukuqina.

Izinzuzo Zokungeniswa Ukuqina Nokuthobisa

I-induction iqinisa futhi iqinise inikeza izinzuzo eziningana zezintambo zensimbi yensimbi, okuhlanganisa:

- Ukuthuthukiswa kokumelana nokugqoka nokuphila kokukhathala

- Ukuqina kwendawo okuthuthukisiwe ngenkathi kugcinwa i-ductile core

- Ukulawula okunembile kokujula okuqinile nobulukhuni bephrofayela

- Izikhathi zokucubungula ezisheshayo uma ziqhathaniswa nezindlela ezijwayelekile zokwelapha ukushisa

- Ukusebenza kahle kwamandla kanye nokushisisa kwendawo, kunciphisa izindleko zizonke

Inqubo Yokukhiqiza Izintambo Zensimbi

Inqubo Yokukhiqiza Izintambo Zensimbi

Ama-Raw material

Izintambo zensimbi zensimbi ngokuvamile zenziwa ngamamaki ensimbi anekhabhoni ephansi noma ephakathi nendawo, njenge-AISI 1018, AISI 1045, noma i-AISI 4140. Lawa mabanga akhethwa ngokusekelwe ezintweni ezifunwayo zemishini kanye nesicelo sokusetshenziswa kokugcina.

Umdwebo Wocingo

Inqubo yokudweba ngocingo ihlanganisa ukudonsa induku yensimbi eqinile ngochungechunge lwamafa anezikhala ezincane ngokuqhubekayo. Le nqubo inweba futhi inciphise indawo ephambanayo yenduku, okuholela kububanzi bocingo obufunekayo kanye nokuqedwa kwendawo.

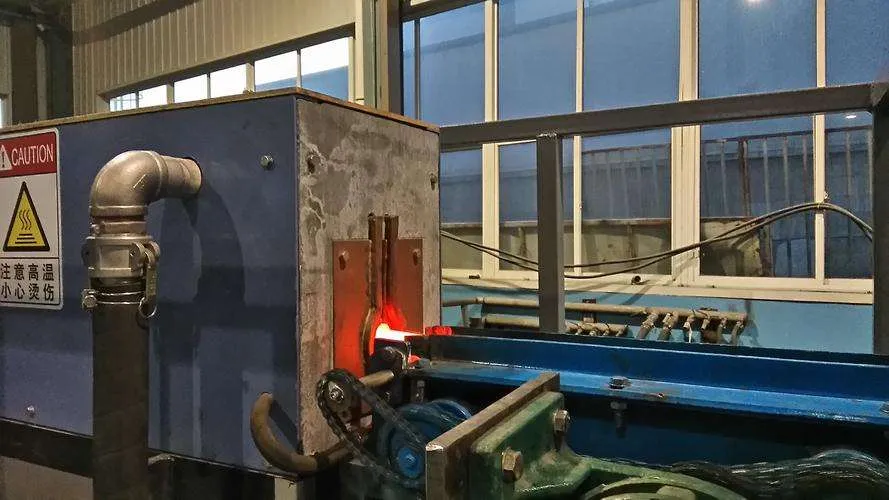

Ukwelashwa Ngokushisa

Ngemva kwenqubo yokudweba ngocingo, izintambo zensimbi zithola ukwelashwa kokushisa ukuze kuzuzwe izici ezifiselekayo zokulungisa. Lokhu ngokuvamile kuhilela ukuqina kwe-induction kanye nezinqubo zokuthambisa.

Inqubo Yokwenza Ukuqina Kwezintambo Zensimbi Yensimbi

Izimiso Zokungeniswa Ukuqina

Ukuqina kokungeniswa kusebenzisa izimiso zokungeniswa kwe-electromagnetic ukukhiqiza ukushisa ngaphakathi kwentambo yensimbi yensimbi. Umsinga oshintshanayo ugeleza kukhoyili yokungeniswa, udale inkambu kazibuthe engenisa ama-eddy currents kwintambo yensimbi. Lawa ma-eddy currents akhiqiza ukushisa ngenxa yokumelana kukagesi kwensimbi, okubangela ukuthi indawo engaphezulu ifinyelele izinga lokushisa le-austenitic (imvamisa engaphezu kuka-1600°F noma 870°C).

Imishini Yokungeniswa Ukuqina

Imishini Yokungeniswa Ukuqina

I-Induction Harding Coils

Amakhoyili e-induction ayinhliziyo yenqubo yokwenziwa lukhuni kwe-induction. Zidizayinelwe ukugxilisa inkambu kazibuthe eduze kwentambo yensimbi yensimbi, iqinisekisa ukufudumeza okusebenzayo nokwasendaweni. Idizayini yekhoyili, okuhlanganisa ukuma kwayo, usayizi, kanye nenani lokujika, ithuthukiselwe uhlelo oluthile.

Izimpahla Zamandla Okushisa Okungenayo

Izinsiza zamandla zihlinzeka ngamanani aphezulu ashintshashintshayo adingekayo ekushisiseni kokungeniswa. Angasebenza kumafrikhwensi asuka ku-kilohertz ambalwa kuya kuma-megahertz ambalwa, kuye ngokujula okudingekile kokushisisa nesivinini sokukhiqiza.

Ukucisha Amasistimu

Amasistimu okucisha asetshenziselwa ukupholisa ngokushesha indawo eshisayo yocingo lwenduku yensimbi ngemva kokushisisa kokungeniswa. Imidiya evamile yokucisha ihlanganisa amanzi, izixazululo ze-polymer, noma umoya ophoqelelwe. Izinga lokucisha libalulekile ekuzuzeni ubulukhuni obufunekayo kanye ne-microstructure.

I-Induction Hardening Parameters

I-Induction Hardening Parameters

imvamisa

Imvamisa yamanje eshintshanayo inquma ukujula kokushisisa kanye nezinga lokushisa. Amafrikhwensi aphezulu aholela ekushiseni okungashoni, kuyilapho amafrikhwensi aphansi engena ajule kokubalulekile.

2. H4: Amandla

Okokufaka kwamandla kulawula izinga lokushisa kanye nezinga lokushisa elitholwe phakathi nenqubo yokuqina kokungeniswa. Ukulawulwa okunembile kwamandla kubalulekile ukuze uqinisekise ukushisa okufanayo futhi ugweme ukushisa ngokweqile noma ukushisa ngaphansi.

Isikhathi

Ubude besikhathi somjikelezo wokushisisa ongeniswayo bunquma ukujula kwekesi eliqinile kanye nokokufaka kokushisa kukonke. Izikhathi zokushisisa ezimfushane zivame ukusetshenziselwa izingxenye ezincane, kuyilapho izikhathi ezinde zidingeka ezingxenyeni eziminyene.

Inqubo Yokushisa Yezintambo Zensimbi Yensimbi

Ukubaluleka Kokuthambisa

Ngemuva kokuqina kokungeniswa, izintambo zensimbi zensimbi zisesimweni esibuhlungu ngenxa yokwakheka kwe-martensite, i-microstructure eqinile kodwa eqinile. Ukushisa kubalulekile ukuze kuncishiswe ukuqina futhi kuthuthukiswe ukuqina kanye nokudumba kwensimbi kuyilapho ugcina ubulukhuni obanele.

Izindlela Zokunciphisa

I-Oven Tempering

Ukufudumeza kukahhavini kubandakanya ukushisa izintambo zensimbi eziqinile esithandweni somoya esilawulwayo ezingeni lokushisa elithile, ngokuvamile eliphakathi kuka-300°F no-1200°F (150°C no-650°C), isikhathi esicacisiwe. Le nqubo ivumela i-martensite ukuthi iguquke ibe yi-microstructure ezinzile futhi ene-ductile.

I-Induction Tempering

I-Induction tempering iyindlela yakamuva nesebenza kahle yokufudumeza izintambo zensimbi. Isebenzisa izimiso ezifanayo njengokuqina kokungeniswa, kodwa emazingeni okushisa aphansi kanye nezikhathi zokushisa ezinde. Le nqubo ivumela ukulawula okunembile kwezinga lokushisa elishisayo futhi ingahlanganiswa nenqubo yokuqina kokungeniswa kokukhiqiza okuthuthukisiwe.

I-Tempering Parameters

Temperature

Izinga lokushisa elipholile libalulekile ekunqumeni izici zokugcina zemishini yocingo lwensimbi yensimbi. Amazinga okushisa aphezulu okushisa ngokuvamile abangela ubulukhuni obuphansi kodwa ukuthuthukiswa kwe-ductility kanye nokumelana nomthelela.

Isikhathi

Isikhathi sokushisa siqinisekisa ukuthi ukuguqulwa kwe-microstructural oyifunayo kwenzeka ngokufanayo kulo lonke icala eliqinile. Kungase kudingeke izikhathi ezinde zokushisa ezigabeni eziwugqinsi noma lapho kuhloswe khona izici ezithile zomshini.

Ukulawulwa Kwekhwalithi Nokuhlolwa

A. Ukuhlola Ukuqina

Ukuhlolwa kokuqina kuyisilinganiso esiyisisekelo sokulawula ikhwalithi sezintambo zensimbi eziqinile neziqinile. Izindlela zokuhlola ubulukhuni ezijwayelekile zifaka ukuhlolwa kwe-Rockwell, Vickers, ne-Brinell. Lezi zivivinyo zihlola iphrofayili yokuqina kuyo yonke ingxenye yocingo, iqinisekisa ukuthi amanani obulukhuni obufunwayo ayafinyelelwa.

B. Ukuhlaziywa Kwezakhiwo Ezincane

Ukuhlaziywa kwe-Microstructure kuhilela ukuhlola ukwakheka kwe-metallurgical kocingo lwenduku yensimbi kusetshenziswa amasu afana ne-optical microscopy noma i-scanning electron microscopy (SEM). Lokhu kuhlaziya kuqinisekisa ukuba khona kwezigaba ze-microstructural ezifiselekayo, njenge- tempered martensite, futhi kuhlonze noma yikuphi ukukhubazeka okungaba khona noma okungewona umfaniswano.

C. Ukuhlolwa Kwemishini

Ukuhlolwa kwemishini, okuhlanganisa ukushuba, ukukhathala, nokuhlolwa komthelela, kwenziwa ukuze kuhlolwe izakhiwo zemishini zezintambo zensimbi eziqinile neziqinile. Lezi zivivinyo ziqinisekisa ukuthi izintambo zihlangabezana nezimfuneko ezicacisiwe zamandla, i-ductility, kanye nokuqina kokusetshenziswa kwazo okuhlosiwe.

Izicelo Zezintambo Zezintambo Zensimbi Eqinile Neziqinile

A. Imboni Yezimoto

A. Imboni Yezimoto

Izintambo zensimbi eziqinisiwe neziqinile zisetshenziswa kabanzi embonini yezimoto ezingxenyeni ezahlukahlukene, njengeziphethu ezimisiwe, iziphethu zamavalvu, nezinto zokudlulisa. Lezi zintambo zinikeza amandla aphezulu, ukumelana nokugqoka, nokuphila kokukhathala, okubalulekile ekusebenzeni okuthembekile nokuhlala isikhathi eside.

B. Imboni Yezokwakha

Embonini yezokwakha, izintambo zensimbi ezingenasici eziqinile neziqinile zisetshenziselwa ukuqinisa ezakhiweni zikakhonkolo, izicelo zikakhonkolo ezicindezelwe ngaphambili, nezintambo zocingo zokhrayini namakheshi. Amandla aphezulu nokuqina kwalezi zintambo kuqinisekisa ukuphepha nokuphila isikhathi eside kwamaphrojekthi wokwakha.

C. Imboni Yokukhiqiza

Imboni yokukhiqiza isebenzisa izintambo zensimbi eziqinile neziqinile ezingenisiwe ezinhlelweni ezihlukene, njengezingxenye zamathuluzi omshini, amabhande okuthutha, nezinsimbi zezimboni. Lezi zintambo zinikeza amandla adingekayo, ukumelana nokugqokwa, kanye nokuzinza kwe-dimensional okudingekayo ezindaweni zokukhiqiza ezidingekayo.

Isiphetho

Isiphetho

A. Isifinyezo

Ukuqina kokungeniswa kanye nokushisa kuyizinqubo ezibalulekile zokwelapha ukushisa kwezintambo zensimbi, okuhlinzeka ngenhlanganisela eyingqayizivele yokuqina kwendawo, ukumelana nokugqokwa, kanye nokuqina okuyisisekelo. Ngokulawula ngokucophelela amapharamitha wokungeniswa kokuqina kanye nokuthobisa, abakhiqizi bangakwazi ukulungisa izakhiwo zemishini yezintambo zensimbi ukuze zihlangabezane nezimfuneko ezithile zezimboni ezihlukahlukene, okuhlanganisa ezezimoto, ezokwakha, nezokukhiqiza.

B. Amathrendi Nentuthuko Yekusasa

Njengoba ubuchwepheshe buqhubeka nokuvela, izinqubo ze-induction ziqina kanye nezokushisa kulindeleke ukuthi zisebenze kahle, ziqonde, futhi zivumelane nemvelo. Intuthuko kubuchwepheshe bokuphakela amandla, idizayini yekhoyili, kanye nezinqubo ezishintshayo kuzothuthukisa ikhwalithi nokuvumelana kwezintambo zensimbi eziqinile neziqinile. Ukwengeza, ucwaningo oluqhubekayo ku-metallurgy nesayensi yezinto ezibonakalayo lungase luholele ekwakhiweni kwama-alloys ensimbi amasha kanye namasu amasha okwelapha ukushisa, kwandiswe izinhlelo zokusebenza namandla okusebenza alezi zintambo.

Imibuzo Evame Ukubuzwa

Imibuzo Evame Ukubuzwa

1. Uyini umehluko phakathi kokuqina kokungeniswa kanye nezinqubo ezijwayelekile zokuqina? Ukuqina kokungeniswa kuyinqubo eyenziwe yasendaweni nesebenza kahle kakhulu uma kuqhathaniswa nezindlela ezijwayelekile zokuqina, njengokuqiniswa kwesithando somlilo noma ukuqinisa ilangabi. Ivumela ukuqina okukhethiwe kwezindawo ezithile ngenkathi kugcinwa i-ductile core, futhi inikeza izikhathi zokucubungula ngokushesha kanye nokusebenza kahle kwamandla.

2. Ingabe ukuqina kokungeniswa kungafakwa kwezinye izinto ngaphandle kwensimbi? Ngenkathi ukuqina kokungeniswa kusetshenziswa ngokuyinhloko ezingxenyeni zensimbi, kungasetshenziswa futhi kwezinye izinto ze-ferromagnetic, njenge-cast iron kanye nama-alloys athile asekelwe ku-nickel. Kodwa-ke, amapharamitha wenqubo kanye nezidingo zingahluka kuye ngokwakhiwa kwento kanye nezakhiwo.

3. Icala eliqinile lingafinyelelwa ngokujula kangakanani ngokuqina kokufakwa? Ukujula kwekesi eliqinile ekuqineni kokungeniswa kuncike ezintweni ezimbalwa, okuhlanganisa imvamisa yamanje eshintshanayo, okokufaka kwamandla, nesikhathi sokushisisa. Ngokuvamile, ukujula kwekesi eliqinile kusuka ku-0.5 mm kuya ku-6 mm, kodwa izimo ezijulile zingafinyelelwa ngamasu akhethekile noma imijikelezo eminingi yokushisisa.

4. Ingabe ukushisa kuhlale kudingekile ngemva kokuqina kokungeniswa? Yebo, ukuthulisa kubalulekile ngemva kokuqina kokungeniswa ukuze kuncishiswe ukuqina kwensimbi eqinile futhi kuthuthukiswe ukuqina nokudumba kwayo. Ngaphandle kokuthulisa, insimbi eqinile ingaba brittle kakhulu futhi ijwayele ukuqhekeka noma ukuqhekeka ngaphansi komthwalo noma umthelela.

5. Ingabe ukuqina nokuthambisa kungenziwa njengenqubo eyodwa edidiyelwe? Yebo, yesimanje amasistimu wokuqina wokungeniswa kuvame ukuhlanganisa inqubo yokushisa nenqubo yokuqina, okuvumela umjikelezo oqhubekayo nophumelelayo wokwelapha ukushisa. Lokhu kuhlanganiswa kusiza ekwandiseni izikhathi zokukhiqiza nokuqinisekisa ikhwalithi engaguquki kuyo yonke inqubo.