Izifudumezi ezishisayo zokungenisa induction-I-Induction heat transfer transfer oil boilers

Incazelo

Izifudumezi ezishisayo zokungenisa induction ziyizinhlelo zokufudumeza ezithuthukisiwe ezisebenzisa izimiso ze ukufakwa kwe-electromagnetic ukushisa ngokuqondile uketshezi olushisayo olujikelezayo.

Izifudumezi zoketshezi ezishisayo zokungeniswa ziye zavela njengobuchwepheshe obuthembisayo emikhakheni eyahlukene yezimboni, enikeza izinzuzo eziningi kunezindlela zokufudumeza zendabuko. Leli phepha lihlola izimiso, idizayini, kanye nokusetshenziswa kwezifudumezi zoketshezi ezishisayo zokungeniswa, ligqamisa izinzuzo zazo nezinselele ezingaba khona. Ngokuhlaziywa okuphelele kokusebenza kahle kwazo kwamandla, ukulawula izinga lokushisa okunembile, kanye nezidingo ezincishisiwe zokunakekelwa, lolu cwaningo lubonisa ukuphakama kobuchwepheshe bokushisisa okungeniswayo ezinqubweni zesimanje zezimboni. Ngaphezu kwalokho, izibonelo zezifundo nokuhlaziya okuqhathanisayo kunikeza imininingwane engokoqobo ekusetshenzisweni ngempumelelo kwezishisi ezishisayo zokungenisa ezitshalweni zamakhemikhali nakwezinye izimboni. Iphepha liphetha ngengxoxo ngamathemba esikhathi esizayo kanye nentuthuko yalobu buchwepheshe, ligcizelela amandla abo okuthuthukisa okwengeziwe nokusungula izinto ezintsha.

I-Parameter yobuchwepheshe

| I-induction uketshezi olushisayo lwe-thermal boiler | I-heater kawoyela engenisiwe | ||||||

| Ukucaciswa Kwesibonelo | I-DWOB-80 | I-DWOB-100 | I-DWOB-150 | I-DWOB-300 | I-DWOB-600 | |

| Ukucindezela kwedizayini (MPa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Ukucindezeleka kokusebenza (i-MPa) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Amandla akalwe (KW) | 80 | 100 | 150 | 300 | 600 | |

| Ilinganise okwamanje (A) | 120 | 150 | 225 | 450 | 900 | |

| Amandla kagesi alinganiselwe (V) | 380 | 380 | 380 | 380 | 380 | |

| Ukwenza kahle hle | ± 1 ° C | |||||

| Ibanga lokushisa (℃) | 0-350 | 0-350 | 0-350 | 0-350 | 0-350 | |

| Ukusebenza kahle kwe-Thermal | 98% | 98% | 98% | 98% | 98% | |

| Inhloko yepampu | 25/38 | 25/40 | 25/40 | 50/50 | 55/30 | |

| Ukugeleza kwepampu | 40 | 40 | 40 | 50/60 | 100 | |

| Amandla Ezimoto | 5.5 | 5.5/7.5 | 20 | 21 | 22 | |

Isingeniso

1.1 Uhlolojikelele lobuchwepheshe bokushisa lokungeniswa

Ukushisa kwe-induction kuyindlela yokushisa engathinteki esebenzisa i-electromagnetic induction ukukhiqiza ukushisa ngaphakathi kwempahla eqondiwe. Lobu buchwepheshe buthole ukunakwa okuphawulekayo eminyakeni yamuva ngenxa yekhono labo lokuhlinzeka ngezixazululo zokushisa ezisheshayo, ezinembile, nezisebenzayo. Ukushisa kokungeniswa kuthola izinhlelo zokusebenza ezinqubweni ezehlukene zezimboni, okuhlanganisa ukwelashwa kwensimbi, ukushisela, nokushisa okushisayo okushisayo (Rudnev et al., 2017).

1.2 Isimiso se-induction thermal fluid heater

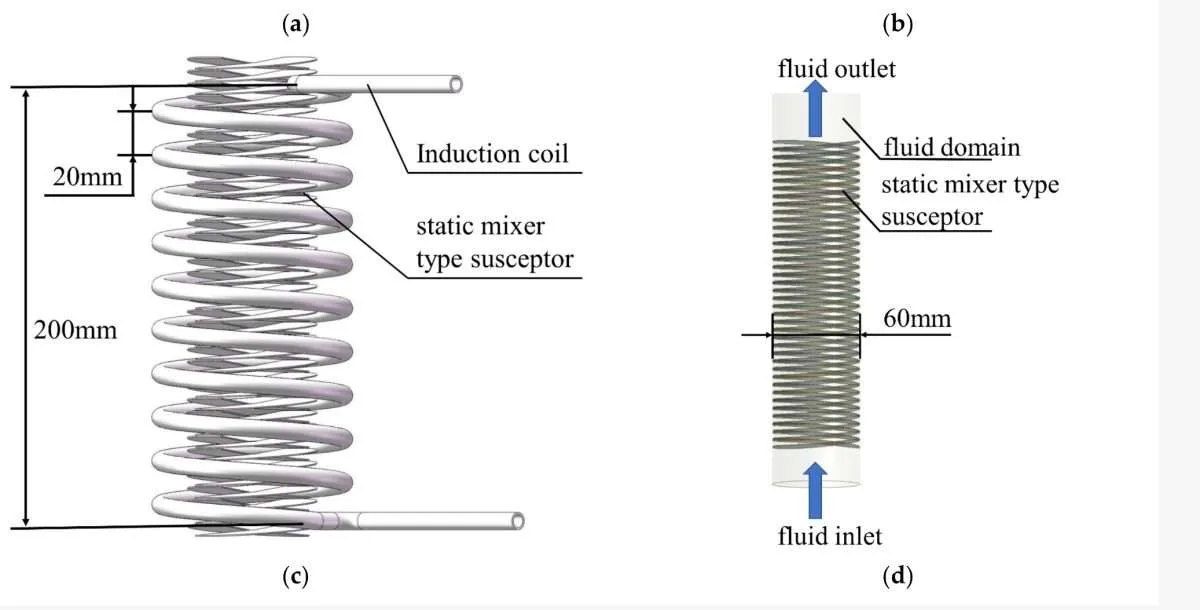

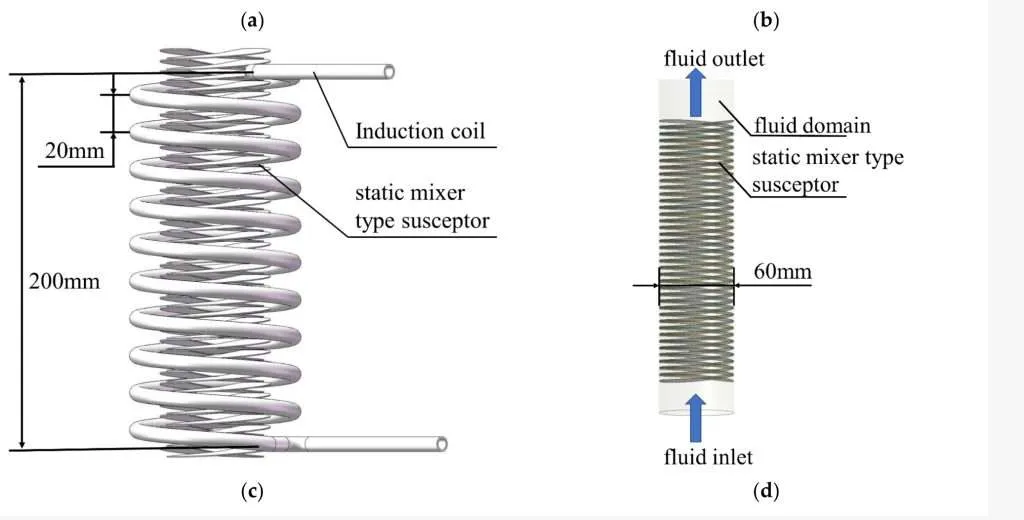

Izifudumezi zoketshezi ezishisayo ze-induction zisebenza ngomgomo wokungeniswa kwe-electromagnetic. Umsinga oshintshanayo udlula kukhoyili, okudala inkambu kazibuthe engenisa ama-eddy currents kwinto eqondiwe eqondiwe. Lawa ma-eddy currents akhiqiza ukushisa ngaphakathi kwezinto ngokufudumeza kwe-Joule (Lucia et al., 2014). Endabeni yezifudumezi zoketshezi ezishisayo ze-induction, into ehlosiwe iwuketshezi olushisayo, olufana nowoyela noma amanzi, olushiswayo njengoba ludlula ikhoyili yokungeniswa.

1.3 Izinzuzo ngaphezu kwezindlela zokushisisa zendabuko

Izifudumezi zoketshezi ezishisayo ezingeniswayo zinikeza izinzuzo ezimbalwa kunezindlela zokushisisa zendabuko, njengezifudumezi ezibaswa ngegesi noma ezisebenza ngogesi. Banikeza ukufudumeza okusheshayo, ukulawula izinga lokushisa okunembile, nokusebenza kahle kwamandla aphezulu (Zinn & Semiatin, 1988). Ukwengeza, izifudumezi zokungenisa umoya zinedizayini ehlangene, izimfuneko zokulungisa ezincishisiwe, nempilo ende yemishini uma kuqhathaniswa nozakwabo bendabuko.

Ukuklama Nokwakhiwa Kwezifudumezi Ezishisayo Ezishisayo Zokungenisa

2.1 Izingxenye ezibalulekile nemisebenzi yazo

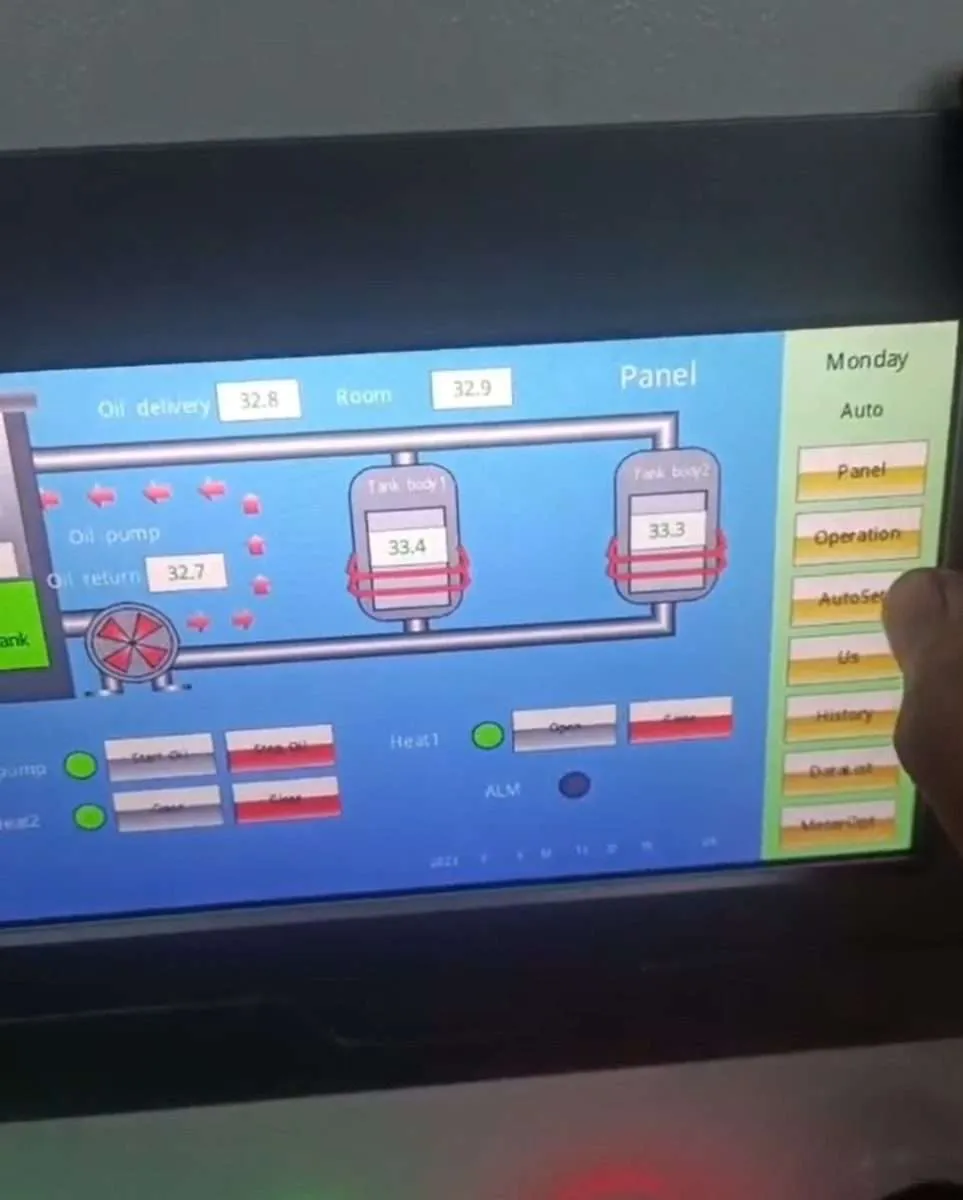

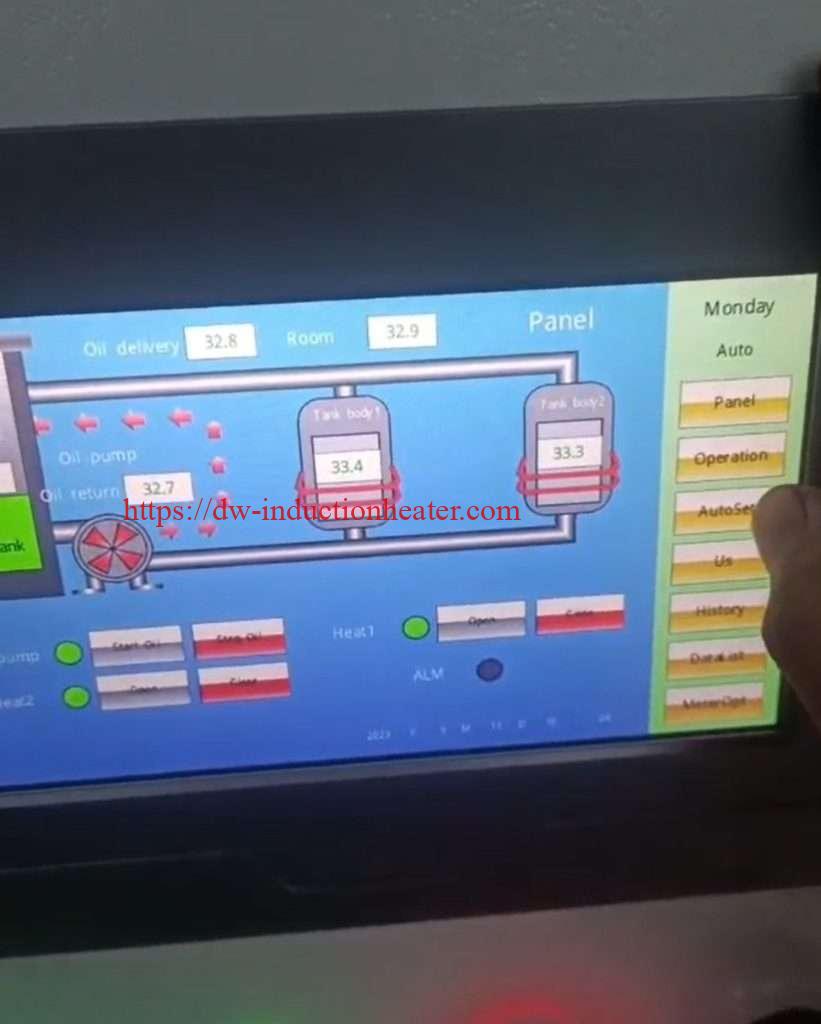

Izingxenye eziyinhloko ze-induction thermal fluid heater zihlanganisa ikhoyili yokungeniswa, ukunikezwa kwamandla, isistimu yokupholisa, kanye neyunithi yokulawula. Ikhoyili yokungeniswa inesibopho sokukhiqiza inkambu kazibuthe eyenza ukushisa oketshezini olushisayo. Ukunikezwa kwamandla kagesi kunikeza amandla ashintshayo kukhoyili, kuyilapho isistimu yokupholisa igcina izinga lokushisa elifanele lezinto zokusebenza. Iyunithi yokulawula ilawula okokufaka kwamandla futhi iqaphe imingcele yesistimu ukuze kuqinisekiswe ukusebenza okuphephile nokusebenza kahle (Rudnev, 2008).

2.2 Izinto ezisetshenziswa ekwakheni

Izinto ezisetshenziswa ekwakhiweni kwe induction thermal fluid heater zikhethwa ngokusekelwe ezintweni zazo zikagesi, kazibuthe, nezishisayo. Ikhoyili yokungeniswa ngokuvamile yenziwe ngethusi noma nge-aluminium, enokuhanjiswa kukagesi okuphezulu futhi engakhiqiza ngempumelelo inkambu kazibuthe edingekayo. Umkhumbi wokuqukatha uketshezi olushisayo wenziwe ngezinto ezinokusebenza kahle kwe-thermal nokumelana nokugqwala, njengensimbi engagqwali noma i-titanium (Goldstein et al., 2003).

2.3 Dizayina ukucatshangelwa kokusebenza kahle nokuqina

Ukuqinisekisa ukusebenza kahle nokuqina okuhle, kufanele kucatshangelwe ukucatshangelwa kwemiklamo eminingana lapho kwakhiwa izifudumezi ezishisayo ezishisayo. Lokhu kufaka phakathi i-geometry yekhoyili yokungeniswa, imvamisa yamanje okushintshanayo, kanye nezakhiwo zoketshezi olushisayo. I-geometry yekhoyili kufanele ithuthukiswe ukuze kwandiswe ukusebenza kahle kokuhlanganisa phakathi kwendawo kazibuthe kanye nokokusebenza okuqondiwe. Imvamisa ye-alternating current kufanele ikhethwe ngokusekelwe esilinganisweni sokushisa esifunwayo kanye nezakhiwo zoketshezi olushisayo. Ukwengeza, isistimu kufanele yakhelwe ukunciphisa ukulahlekelwa ukushisa futhi iqinisekise ukushisa okufanayo koketshezi (Lupi et al., 2017).

Izicelo Ezimbonini Ezihlukahlukene

3.1 Ukucubungula amakhemikhali

Izifudumezi zoketshezi ezishisayo zokungenisa induction zithola ukusetshenziswa okubanzi embonini yokucubungula amakhemikhali. Zisetshenziselwa ukushisa imikhumbi yokusabela, amakholomu e-distillation, nezishintshi zokushisa. Ukulawula izinga lokushisa okunembile namandla okushisa asheshayo ama-heaters angeniswayo anika amandla amazinga okusabela asheshayo, ikhwalithi yomkhiqizo ethuthukisiwe, kanye nokunciphisa ukusetshenziswa kwamandla (Mujumdar, 2006).

3.2 Ukukhiqiza ukudla neziphuzo

Embonini yokudla neziphuzo, izifudumezi zoketshezi ezishisayo ezifakwa ngaphakathi zisetshenziswa ukuze kufakwe i-pasteurization, inzalo, nezinqubo zokupheka. Banikeza ukufudumeza okufanayo nokulawula izinga lokushisa okunembile, ukuqinisekisa ikhwalithi nokuphepha komkhiqizo okungaguquki. Izifudumezi zokungeniswa ziphinde zinikeze inzuzo yokunciphisa ukungcola nokuhlanza okulula uma kuqhathaniswa nezindlela zokushisa zendabuko (Awuah et al., 2014).

3.3 Ukukhiqizwa kwemithi

Izifudumezi zoketshezi ezishisayo zokungenisa induction zisetshenziswa embonini yezemithi ngezinqubo ezahlukahlukene, okuhlanganisa ukucwiliswa kwamanzi, ukomiswa, kanye nokuvala inzalo. Ukulawulwa okunembile kwezinga lokushisa kanye namandla okushisa okusheshayo ama-heaters angenayo kubalulekile ekugcineni ubuqotho kanye nekhwalithi yemikhiqizo yemithi. Ukwengeza, idizayini ehlangene yamahitha okungenisa ivumela ukuhlanganiswa kalula emigqeni yokukhiqiza ekhona (Ramaswamy & Marcotte, 2005).

3.4 Ipulasitiki kanye nokucubungula kwerabha

Embonini yepulasitiki nenjoloba, izifudumezi ezishisayo zokufakelwa zisetshenziselwa ukubumba, ukukhipha, kanye nezinqubo zokuphulukisa. Ukushisisa okufanayo nokulawula izinga lokushisa okunembile okunikezwa izifudumezi zokungeniswa kuqinisekisa ikhwalithi yomkhiqizo engaguquki kanye nezikhathi zomjikelezo ezincishisiwe. Ukushisa kwe-induction nakho kunika amandla ukuqalisa okusheshayo nokushintshashintsha, ukuthuthukisa ukusebenza kahle kokukhiqiza okuphelele (I-Goodship, 2004).

3.5 Imboni yephepha ne-pulp

Izifudumezi zoketshezi ezishisayo zokungenisa induction zithola izinhlelo zokusebenza embonini yephepha ne-pulp zokomisa, ukufudumeza, kanye nezinqubo zokuhwamuka. Banikeza ukufudumeza okusebenzayo nokufanayo, ukunciphisa ukusetshenziswa kwamandla nokuthuthukisa ikhwalithi yomkhiqizo. Idizayini ehlangene yamahitha okungenisa ivumela ukuhlanganiswa kalula kumshini wokugaya amaphepha okhona kakade (Karlsson, 2000).

3.6 Ezinye izinhlelo zokusebenza ezingaba khona

Ngaphandle kwezimboni ezishiwo ngenhla, izifudumezi zoketshezi ezishisayo ezingeniswayo zinamandla okusetshenziswa kweminye imikhakha ehlukahlukene, njengokucutshungulwa kwezindwangu, ukulahlwa kukadoti, kanye nezinhlelo zamandla avuselelekayo. ukufuna izixazululo zokushisa ezonga amandla nezinembayo, isidingo sezifudumezi ezishisayo ezifakwa ngaphakathi kulindeleke ukuthi sikhule.

Izinzuzo Nezinzuzo

4.1 Ukusebenza kahle kwamandla nokonga izindleko

Enye yezinzuzo eziyinhloko zezifudumezi zoketshezi ezishisayo zokungenisa induction ukusebenza kahle kwazo okuphezulu. Ukushisa kwe-induction kukhiqiza ngokuqondile ukushisa ngaphakathi kwempahla eqondiwe, kunciphisa ukulahlekelwa ukushisa endaweni ezungezile. Lokhu kubangela ukongiwa kwamandla kufika ku-30% uma kuqhathaniswa nezindlela zokushisisa zendabuko (Zinn & Semiatin, 1988). Ukusebenza kahle kwamandla okuthuthukisiwe kuhumusha izindleko zokusebenza ezincishisiwe kanye nomthelela ophansi kwemvelo.

4.2 Ukulawula izinga lokushisa okunembile

Izifudumezi ezishisayo ze-induction zinikeza ukulawula izinga lokushisa okunembile, okuvumela ukulawulwa okunembile kwenqubo yokushisisa. Ukusabela okusheshayo kokushisa kwe-induction kuvumela ukulungiswa okusheshayo ekushintsheni kwezinga lokushisa, ukuqinisekisa ikhwalithi yomkhiqizo engaguquki. Ukulawulwa kwezinga lokushisa okunembile futhi kunciphisa ubungozi bokushisa ngokweqile noma ukushisa okuphansi, okungaholela ekulimaleni komkhiqizo noma ezingozini zokuphepha (Rudnev et al., 2017).

4.3 Ukushisisa okusheshayo kanye nesikhathi esincishisiwe sokucubungula

Ukushisa kwe-induction kunikeza ukufudumeza okusheshayo kwezinto ezihlosiwe, kunciphisa kakhulu izikhathi zokucubungula uma kuqhathaniswa nezindlela zokushisa zendabuko. Amazinga okushisa asheshayo anika amandla izikhathi zokuqalisa ezimfushane kanye noshintsho olusheshayo, athuthukisa ukusebenza kahle kokukhiqiza kukonke. Isikhathi esincishisiwe sokucubungula siphinde siholele ekukhuleni kokuphuma kanye nokukhiqiza okuphezulu (Lucia et al., 2014).

4.4 Ikhwalithi yomkhiqizo ethuthukisiwe kanye nokuvumelana

Ukushisisa okufanayo kanye nokulawula izinga lokushisa okunembile okunikezwa izifudumezi zoketshezi ezishisayo zokungeniswa kuholela ekuthuthukisweni kwekhwalithi yomkhiqizo nokuvumelana. Amandla okushisa asheshayo nawokupholisa ama-heaters anciphisa ubungozi begradient ezishisayo futhi aqinisekise izakhiwo ezifanayo kuwo wonke umkhiqizo. Lokhu kubaluleke kakhulu ezimbonini ezifana nokucubungula ukudla kanye nemithi, lapho ikhwalithi yomkhiqizo nokuphepha kubaluleke kakhulu (Awuah et al., 2014).

4.5 Ukugcinwa okuncishisiwe nokuhlala isikhathi eside kwemishini

Izifudumezi zoketshezi ezishisayo zokungeniswa zinciphise izidingo zokunakekela uma ziqhathaniswa nezindlela zokushisisa zendabuko. Ukungabi bikho kwezingxenye ezihambayo kanye nemvelo engathinteki yokushisisa okungeniswayo kunciphisa ukuguga nokudabuka kwezinto zokusebenza. Ukwengeza, idizayini ehlangene yezifudumezi ezingeniswayo inciphisa ubungozi bokuvuza nokugqwala, iqhubekisele phambili isikhathi sokuphila kwemishini. Izidingo zesondlo ezincishisiwe ziholela ezindlekweni eziphansi zesikhathi sokuphumula nezokulungisa (Goldstein et al., 2003).

Izinselelo Nentuthuko Yekusasa

5.1 Izindleko zokutshala izimali zokuqala

Enye yezinselelo ezihambisana nokwamukelwa kwezifudumezi zoketshezi ezishisayo zokungeniswa yizindleko zokuqala zokutshala imali. Imishini yokushisisa yokungeniswa ngokuvamile ibiza kakhulu kunezinhlelo zokushisisa zendabuko. Kodwa-ke, izinzuzo zesikhathi eside zokusebenza kahle kwamandla, ukulungiswa okuncishisiwe, kanye nekhwalithi yomkhiqizo ethuthukisiwe kuvame ukuthethelela ukutshalwa kwezimali kokuqala (Rudnev, 2008).

5.2 Ukuqeqeshwa komqhubi kanye nokucatshangelwa kokuphepha

Ukuqaliswa kwe induction thermal fluid heater idinga ukuqeqeshwa okufanele komsebenzisi ukuze kuqinisekiswe ukusebenza okuphephile nokusebenza kahle. Ukushisisa okungeniswayo kuhilela amaza kagesi anemvamisa ephezulu kanye nezinkundla eziqinile zikazibuthe, ezingabeka izingozi zokuphepha uma zingaphathwa kahle. Ukuqeqeshwa okwanele kanye nezinqubo zokuphepha kufanele zibe khona ukuze kuncishiswe ingozi yezingozi futhi kuqinisekiswe ukuthotshelwa kwemithetho efanele (Lupi et al., 2017).

5.3 Ukuhlanganiswa nezinhlelo ezikhona

Ukuhlanganiswa kwezifudumezi zoketshezi ezishisayo zokungeniswa ezinqubweni ezikhona zezimboni kungaba yinselele. Kungase kudinge ukuguqulwa kwingqalasizinda ekhona kanye nezinhlelo zokulawula. Ukuhlelwa okufanele nokuxhumana kuyadingeka ukuze kuqinisekiswe ukuhlanganiswa okungenazihibe futhi kuncishiswe ukuphazamiseka ekusebenzeni okuqhubekayo (Mujumdar, 2006).

5.4 Amathuba okwenza okwengeziwe kanye nokuqamba okusha

Naphezu kwentuthuko yobuchwepheshe bokushisisa induction, asekhona amandla okwenza okwengeziwe nokwenza izinto ezintsha. Ucwaningo oluqhubekayo lugxile ekuthuthukiseni ukusebenza kahle, ukwethembeka, kanye nokuguquguquka kwezifudumezi zoketshezi ezishisayo zokungeniswa. Izindawo ezithakaselwayo zifaka ukuthuthukiswa kwezinto ezithuthukisiwe zamakhoyili wokungenisa, ukwenziwa kahle kwamakhoyili wejometri, nokuhlanganiswa kwezinhlelo zokulawula ezihlakaniphile zokuqapha nokulungiswa kwesikhathi sangempela (Rudnev et al., 2017).

Case Studies

6.1 Ukuqaliswa ngempumelelo embonini yamakhemikhali

Ucwaningo olwenziwe nguSmith et al. (2019) iphenye ukuqaliswa ngempumelelo kwezishisi ezishisayo zokufakelwa endaweni yokucutshungulwa kwamakhemikhali. Lesi sikhungo sashintsha izifudumezi zaso zendabuko ezibaswa ngegesi safaka izifudumezi ezingeniswayo ukuze kuqhutshekwe nenqubo yokukhishwa kwe-distillation. Imiphumela ibonise ukwehla ngo-25% kokusetshenziswa kwamandla, ukukhuphuka ngo-20% kwamandla okukhiqiza, kanye nokuthuthukiswa kwekhwalithi yomkhiqizo ngo-15%. Isikhathi sokukhokha se-investimenti yokuqala sibalwe ukuthi sibe ngaphansi kweminyaka emibili.

6.2 Ukuhlaziya okuqhathanisa nezindlela zokushisisa zendabuko

Ukuhlaziya okuqhathanisayo kukaJohnson and Williams (2017) kuhlaziye ukusebenza kwezishisi ezishisayo ezifakwayo uma kuqhathaniswa nezifudumezi zendabuko ezimelana nogesi endaweni yokucubungula ukudla. Ucwaningo luthole ukuthi ama-heaters asebenzisa amandla angaphansi ngo-30% futhi anesikhathi eside esingu-50% sempilo yemishini uma kuqhathaniswa nezifudumezi ezikwazi ukumelana nogesi. Ukulawulwa okunembile kwezinga lokushisa okunikezwa ama-heaters angeniswayo nakho kuholele ekwehleni ngo-10% kokulimala komkhiqizo kanye nokwenyuka okungama-20% ekusebenzeni kahle kwemishini yonke (OEE).

Isiphetho

7.1 Isifinyezo samaphuzu abalulekile

Leli phepha lihlole intuthuko kanye nokusetshenziswa kwama-heaters ashisayo e-induction embonini yesimanje. Izimiso, ukucatshangelwa kwedizayini, kanye nezinzuzo zobuchwepheshe bokufudumala kwe-induction kuxoxwe ngakho ngokuningiliziwe. Ukuguquguquka kwezifudumezi zoketshezi ezishisayo zokungenisa ngaphakathi ezimbonini ezihlukahlukene, okuhlanganisa ukucubungula amakhemikhali, ukukhiqiza ukudla neziphuzo, ezemithi, amapulasitiki nenjoloba, kanye nephepha ne-pulp, kugqanyisiwe. Izinselele ezihambisana nokwamukelwa kokushisisa okungeniswayo, njengezindleko zokuqala zokutshala izimali kanye nokuqeqeshwa kwabasebenzisa izinsiza, nazo sezixazululiwe.

7.2 Umbono wokutholwa nokuthuthuka kwesikhathi esizayo

Izibonelo zezifundo nokuhlaziya okuqhathanisayo okwethulwe kuleli phepha kubonisa ukusebenza okuphezulu kwezifudumezi zoketshezi ezishisayo ezingeniswayo kunezindlela zokushisisa zendabuko. Izinzuzo zokusebenza kahle kwamandla, ukulawula izinga lokushisa okunembile, ukushisisa ngokushesha, ikhwalithi yomkhiqizo ethuthukisiwe, nokulungiswa okuncishisiwe kwenza ukushisisa okungeniswayo kube ukukhetha okukhangayo kwezinqubo zesimanje zezimboni. Njengoba izimboni ziqhubeka nokubeka phambili ukusimama, ukusebenza kahle, kanye nekhwalithi yomkhiqizo, ukwamukelwa kwe induction thermal fluid heater kulindeleke ukuthi ikhule. Ukuthuthuka okwengeziwe ezintweni zokwakha, ukwenziwa ngcono kwedizayini, nezinhlelo zokulawula kuzoqhuba ukuthuthukiswa kwekusasa kwalobu buchwepheshe, kuvule amathuba amasha okusetshenziswa kokushisisa kwezimboni.