I-Cylinder Hardening Scanner-Skena Induction Isilinda Sokucisha kanye ne-Shaft

Incazelo

Ukuqonda I-Induction Cylinder Hardening Scanner

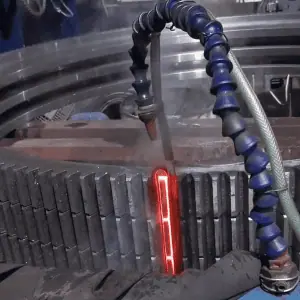

Ukuqina kokungeniswa kuyinqubo lapho isilinda sensimbi sivezwa khona kumaza aphezulu ashintshashintshayo, okukhiqiza amandla kazibuthe ashubile futhi ashintshana ngokushesha azungezile. Lokhu kubangela ukushisa ukuthi kukhiqizwe ngaphakathi kwe-cylinder ngokusebenzisa i-induction, okubuye kwandise ubulukhuni bayo nokumelana nokugqoka nokukhathala. An isithwebuli se-induction cylinder hardening ibalulekile ekwengameleni nasekuqinisekiseni lolu shintsho, ukuqinisekisa ukufana kanye nokutholakala kwezakhiwo ezidingekayo zemishini.

Isingeniso Se-Induction Harding

Iyini i-Induction Hardening?

Ukuqina kwe-induction kuyinqubo yokwelapha ukushisa esetshenziselwa ukuthuthukisa ubulukhuni bensimbi nezinye izakhi ze-alloy. Ngokukhetha yenza lukhuni izindawo ezithandwa kakhulu ukugqokwa nokucindezeleka, inwebe ngokuphawulekayo impilo nokusebenza kwesilinda ngaphandle kokuphazamisa ukuqina kwayo.

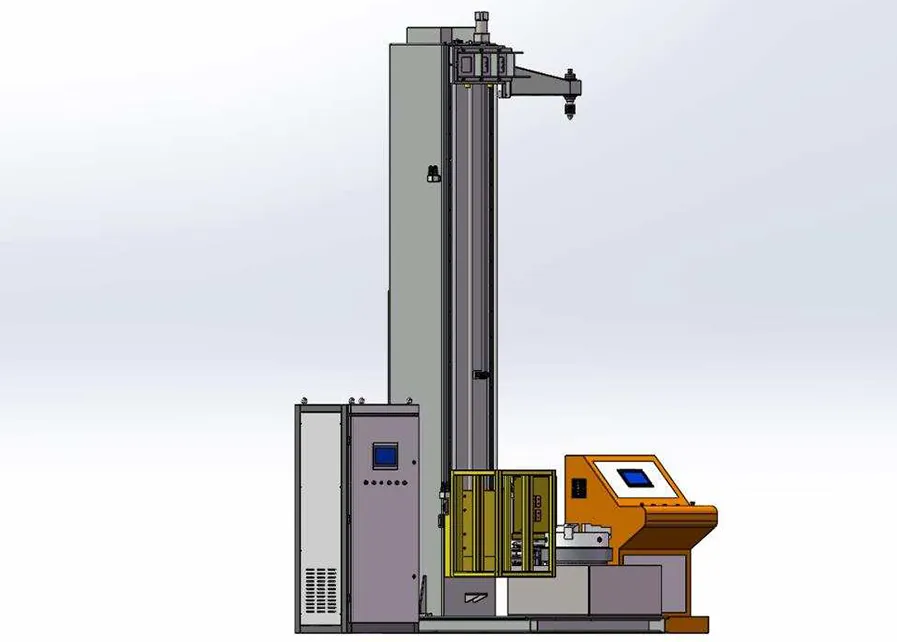

Izingxenye kanye Nokusetshenzwa Kweskena Sokungeniswa Kokuqina

Izinto Ezibalulekile Zeskena

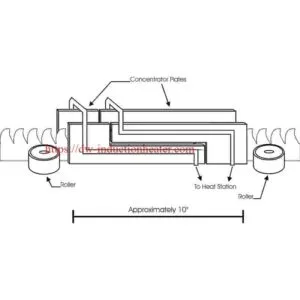

The isithwebuli sokuqina sokungeniswa ngokuvamile iqukethe ikhoyili yokungeniswa, isistimu yokucisha, nezinzwa eziningi eziqapha izinga lokushisa, ukuqina, namanye amapharamitha abalulekile ngesikhathi sangempela ukuze kuqinisekiswe ukuthi inqubo ihlala ngaphakathi kokucaciswa okunqunywe kusengaphambili.

Ihlaziya Amaphethini Okuqina Ngezinzwa Ezithuthukile

Ngokusetshenziswa kwezinzwa eziyinkimbinkimbi, isithwebuli sifunda izinguquko ezingaphezulu nezingaphansi komhlaba njengoba inqubo yokufaka ukuqina kwe-induction iqhubeka. Izinzwa zibika idatha yesikhathi sangempela ebonisa ukuthi ubulukhuni obufunekayo buyafinyelelwa noma uma kudingeka ukulungiswa.

Izinhlelo zokusebenza kanye nezinzuzo zama-Induction Cylinder Hardening Scanners

Iqhaza Leskena Ekuqinisekiseni Ikhwalithi

Indima eyinhloko yesikena sokungeniswa siqinisa isilinda ukuqinisekisa ukuthi isilinda ngasinye sihlangabezana namabhentshimakhi ekhwalithi aqinile. Ngokunikeza impendulo esheshayo ngenqubo yokuqina, iqinisekisa ukunemba nokufana.

Izindlela Ezintsha Ezithuthukisa Inqubo Yokungeniswa Kokuqina

Ukuthuthuka kwezobuchwepheshe kuvule indlela yokuthi izikena zokuqina kwe-induction zibe neziguquguqukayo nezinembe kakhudlwana. Ukuqamba okusha kuvame ukufaka ukuhlaziya kwedatha okuthuthukisiwe kanye nokuhlanganiswa kwe-AI ukulungisa kahle inqubo ngamasistimu okulawula okuguquguqukayo.

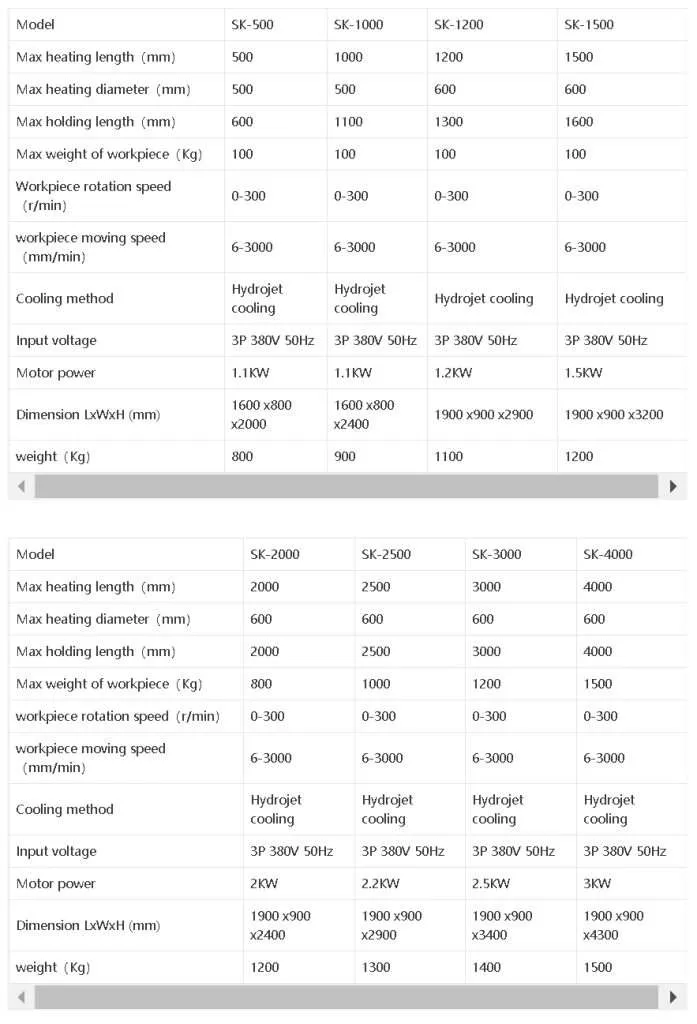

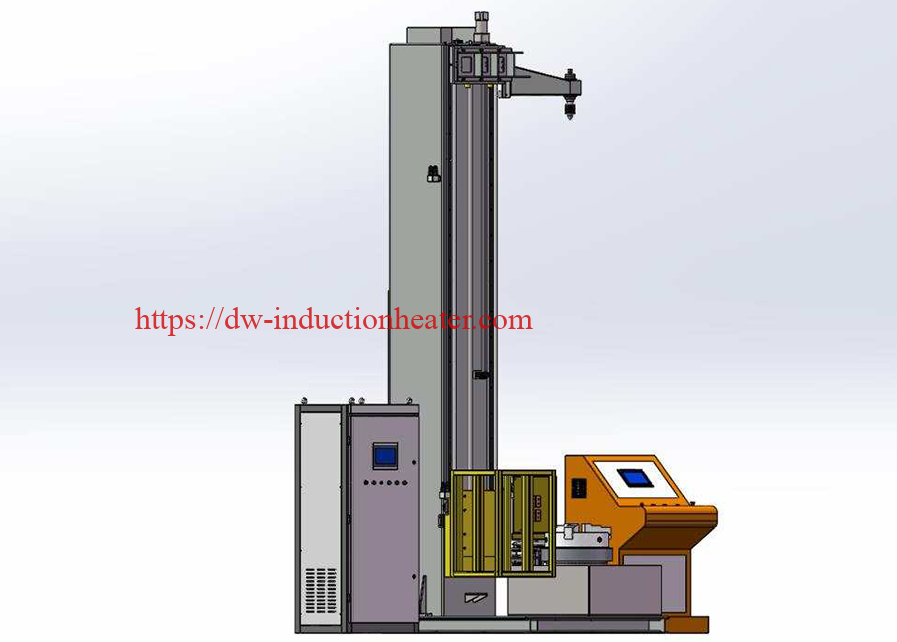

Amathuluzi Omshini Weskena Sokungeniswa Isilinda Esiqinile

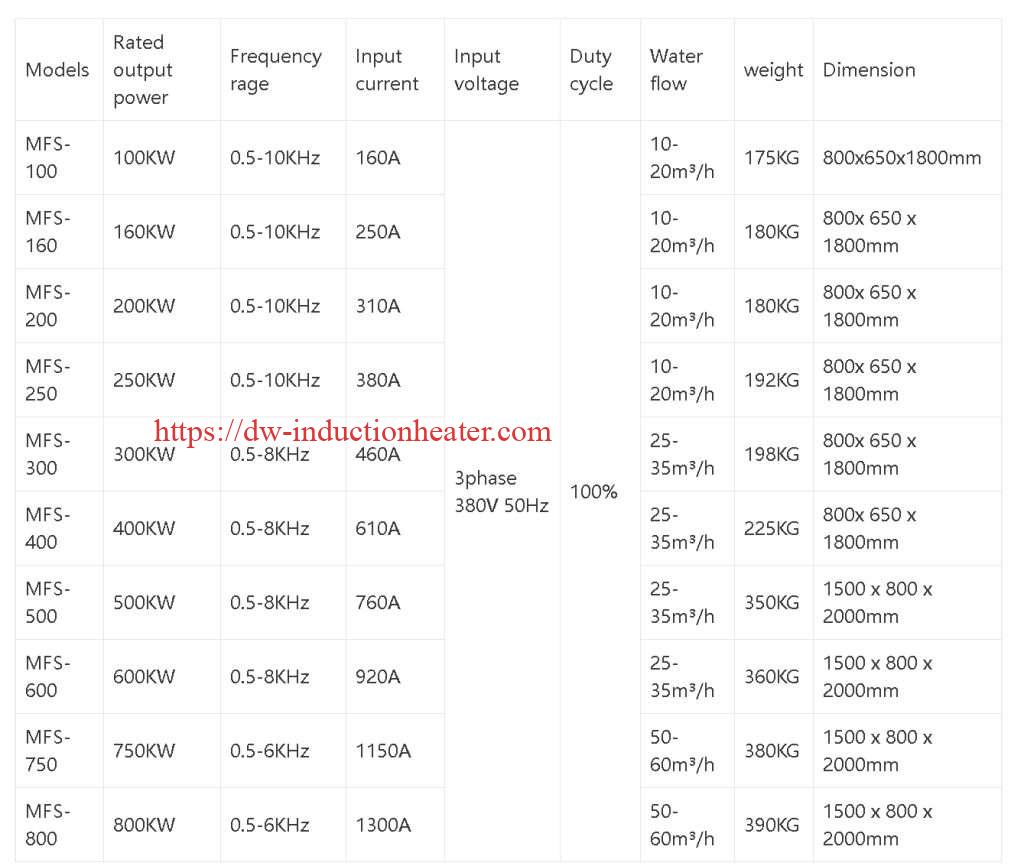

I-Induction Harding Power Supply

Imibuzo Evame Ukubuzwa Ngezikena Zokuqinisa Isilinda Sokungeniswa

I-Q1: Isithwebuli se-induction sithuthukisa kanjani inqubo yokuqina?

I-A1: Ithuthukisa inqubo ngokunikeza idatha yesikhathi sangempela kanye nempendulo, iqinisekisa ukuthi insimbi ifinyelela ezingeni eliqondile lobulukhuni obudingekayo ngekhwalithi engaguquki kuzo zonke izingxenye.

I-Q2: Ingabe izikena zokuqina kwe-induction zingathola izingozi zokushisa ngokweqile?

I-A2: Yebo, ingxenye yendima yesithwebuli iwukuqapha amazinga okushisa eduze kuyo yonke inqubo, ngaleyo ndlela kuvinjwe ukushisa ngokweqile, okungase kubangele ukungqubuzana noma okunye ukukhubazeka.

I-Q3: Ingabe kunesikhathi sokuphumula esibalulekile esihilelekile lapho kufakwa isithwebuli sokuqina sokungenisa emgqeni wokukhiqiza?

I-A3: Nakuba ukufaka kungase kudinge isikhathi sokuphumula ukuze kuhlanganiswe isithwebuli kumasistimu akhona, ukusebenza kahle kwesikhathi eside kanye nokuthuthukiswa kokuqinisekisa ikhwalithi ngokuvamile kuyakudlula lokhu kumiswa kwesikhashana ekukhiqizeni.

I-Q4: Ingabe lezi zithwebuli ziyahambisana nazo zonke izinhlobo zemishini yokuqinisa i-induction?

I-A4: Iningi izikena zokuqina zokungeniswa zenzelwe ukuthi zivumelane nemishini ehlukahlukene kanye nokusetha. Kodwa-ke, ukucaciswa okuthile nokuhlola ukuhambisana kufanele kwenziwe ngaphambi kokuhlanganiswa.

I-Q5: Hlobo luni lokugcinwa oludingekayo ukuze kufakwe izikena zokuqina?

I-A5: Ukunakekelwa okuvamile kufanele kufake phakathi ukubuyekezwa kwesofthiwe, ukulinganiswa kwezinzwa, nokuhlolwa okujwayelekile ukuze kuqinisekiswe ukuthi zonke izingxenye zisebenza ngendlela efanele. Lokhu kusiza ekugcineni ukunemba nokuthembeka kwesithwebuli.

Izikena zokuqinisa isilinda sokungeniswa zivame ukusetshenziswa ezimbonini ezifana nezezimoto, i-aerospace, kanye neyokukhiqiza, lapho ukulawula okunembayo nokuhlolwa kwezingxenye zesilinda esiqinile kubalulekile ngekhwalithi nokuthembeka komkhiqizo.