Uhlelo lokungeniswa kwe-RPR

Ukususwa kwe-RPR Heat Induction isebenza ngomgomo wokungeniswa.I-RPR induction coating remove-i-RPR induction disbonding ia indlela esheshayo, ephephile nehlanzekile yokususa izimbobo zezimboni ezindaweni zensimbi.

Umshini Wokukhwabanisa Ukukhishwa

Induction amabhola Okudala Isithando

Amabhilidi e-induction akha isithando somlilo iyisethi yomshini wokubumba ozenzakalelayo noma ophelele wokubumba izinsimbi ngaphambi kokuguqulwa usebenzisa umshini wokunyathelisa noma isando ukukhulisa ukusebenziseka kwawo kanye nokugeleza kosizo kumshini wokubumba.

Umshini wokushisa we-PWHT

Umshini wokushisa we-PWHT usetshenziselwa ukukhishwa kwepayipi yokushisa ngaphambi kokushisa, ukulandela ukushisa kwe-weld ukushisa, ukushisa imipayipi yokushisa, ukunxusa ukucindezeleka ukuxilonga, ukumisa ukushisa, njll.

Izitshalo Zokukhishwa Kwamaminerali

Izitshalo zensimbi eziqhakazile izinsimbi zisebenzisa ukufakelwa kwamandla kagesi ukuze kuguqulwe amandla kagesi zibe amandla okushisa ngokusebenzisa isilawuli sokushisa.

Umshini Wokubamba Ngezingodo

Ukukhishwa kwe-induction ukwethulwa kwezinsimu zikamasipala zibe yizidumbu zensimbi ukuze kuthunjiswe amalunga phakathi kwezingxenye bese kucibilika i-alloy ngezinga lokushisa eliphansi kunezingxenye.

I-Brazing

Ukukhishwa kwe-induction yinqubo lapho izinto eziningi zihlanganiswa khona nge-filler metal enezinga eliphansi lokuqhakazila kunezinto ezisisekelo zokusebenzisa ukushisa.

Annealing

I-Annealing ye-Induction iyindlela yokwelashwa yensimbi lapho izinto zensimbi zivezwa khona ukushisa okuphakeme isikhathi esithile futhi bese sehlile kancane kancane.

I-PWHT

Ukuze kuqinisekiswe ukuthi amandla okusebenza enxenye agcinwe ngemuva kokudonsa,I-Post Weld Heat Treatment (PWHT) kunciphisa ukucindezeleka okusalayo okwakhiwa ngenkathi kufakwe welding

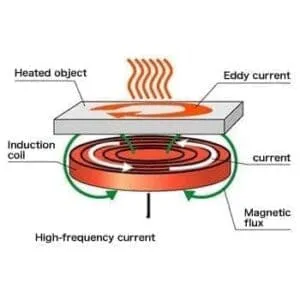

Isimiso sokushisa ukukhipha

Ukushisa ukushisa uhlobo lwe Ukushisa okungaxhunyiwe zezinto zokwazisa, lapho kuguqulwa okugeleza kwamanje kwikhoyili efakiwe, kusetshenziselwa insimu kagesi ehlukahlukene ijikeleza ikhoyili, isitha samanje (esifakiwe, samanje, samanje se-eddy) sikhiqizwa endaweni yokusebenzela (into esetshenziswayo), ukushisa kukhiqizwa njenge-eddy yamanje igeleza imelana nokuma kwezinto

Ukushisa ukushisa ifomu lokufudumala eliphuthumayo, elihlanzekile, elihlanzekile, elingcolile elingasetshenziselwa ukushisa izinsimbi noma ukuguqula izakhiwo eziphathekayo. Ikhoyili ngokwayo ayishisi futhi umphumela wokushisa uphansi kokulawulwa. I-state eqinile ye-transistor technology iye yenze Ukushisa ukufakelwa kulula kakhulu, ukushisa okungabizi kahle kwezicelo kufaka phakathi i-soldering futhi Ukukhishwa kwesibalo ,ukukhipha ukushisa kokufakelwa, ukuchithwa kwe-induction,ukukhishwa kwe-induction njll