Ukwenziwa Ukuqina Kokungeniswa KwamaShaft namaSilinda anobubanzi obukhulu

Isingeniso

A. Incazelo yokuqina kokungeniswa

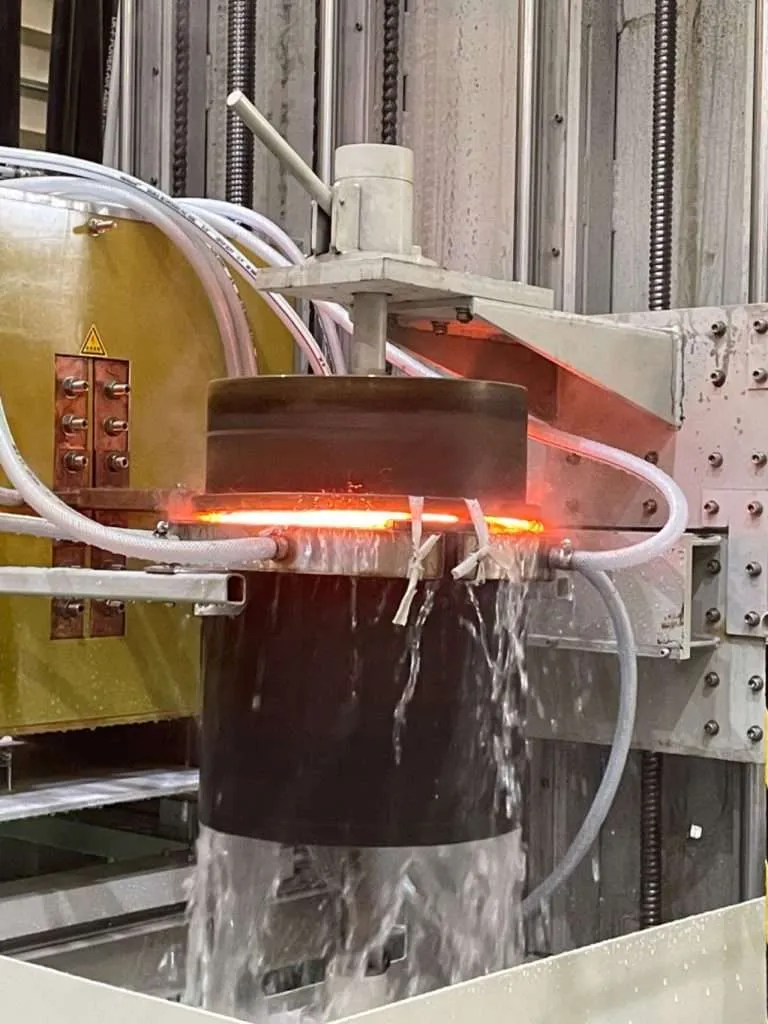

I-Hardenin yokungeniswag iyinqubo yokwelapha ukushisa eyenza ngokukhetha lukhuni ingaphezulu lezingxenye zensimbi kusetshenziswa ukungeniswa kwe-electromagnetic. Isetshenziswa kabanzi ezimbonini ezahlukahlukene ukuthuthukisa ukumelana nokugqokwa, amandla okukhathala, nokuqina kwezingxenye ezibalulekile.

B. Ukubaluleka kwezingxenye ezinobubanzi obukhulu

Amashafti namasilinda anobubanzi obukhulu yizinto ezibalulekile ezisetshenziswayo eziningi, kusukela emishinini yezimoto neyezimboni kuya kumasistimu asebenza ngamanzi kanye nawomoya. Lezi zingxenye zingaphansi kokucindezeleka okukhulu nokuguga ngesikhathi sokusebenza, okudinga indawo eqinile futhi ehlala njalo. Ukuqina kwe-induction kudlala indima ebalulekile ekuzuzeni izakhiwo ezifiselekayo ngenkathi kugcinwa ukuqina nokuqina kwento esemqoka.

II. Izimiso Zokungeniswa Ukuqina

A. Indlela yokushisisa

1. Ukungeniswa kwe-Electromagnetic

The inqubo yokwenza lukhuni incike kumgomo wokungeniswa kwe-electromagnetic. Umsinga oshintshanayo ugeleza kukhoyili yethusi, udale inkambu kazibuthe eshintshana ngokushesha. Uma ucezu olusebenza ngogesi lufakwa ngaphakathi kwale nkambu kazibuthe, ama-eddy currents angeniswa ngaphakathi kwento, okuyenza ishise.

2. Umphumela wesikhumba

Umphumela wesikhumba uyinto lapho imisinga ye-eddy eyenziwe igxile eduze kwendawo yokusebenza. Lokhu kubangela ukushisa okusheshayo kongqimba olungaphezulu kuyilapho kunciphisa ukudluliswa kokushisa kungqikithi. Ukujula kwekesi eliqinile kungalawulwa ngokulungisa imvamisa yokungeniswa kanye namazinga wamandla.

B. Iphethini yokushisa

1. izindandatho Concentric

Ngesikhathi sokuqina kokungeniswa kwezingxenye ezinobubanzi obukhulu, iphethini yokushisa ngokuvamile yakha izindandatho ezigxile phezulu. Lokhu kungenxa yokusatshalaliswa kwensimu kazibuthe kanye namaphethini wamanje we-eddy.

2. Imiphumela yokuphela

Emaphethelweni ocezu lokusebenza, imigqa yamagnetic field ijwayele ukuhlukana, okuholela kuphethini yokushisa engalingani eyaziwa ngokuthi umphumela wokuphela. Lesi simo sidinga amasu athile okuqinisekisa ukuqina okungaguquki kuyo yonke ingxenye.

III. Izinzuzo ze-Induction Harding

A. Ukuqina okukhethekile

Enye yezinzuzo eziyinhloko zokuqina kokungeniswa yikhono lakhona lokuqinisa izindawo ezithile zengxenye. Lokhu kuvumela ukuthuthukiswa kokumelana nokugqoka namandla okukhathala ezindaweni ezibucayi ngenkathi kugcinwa i-ductility kanye nokuqina ezindaweni ezingabalulekile.

B. Ukuhlanekezela okuncane

Uma kuqhathaniswa nezinye izinqubo zokwelashwa kokushisa, ukuqina kwe-induction kubangela ukuhlanekezela okuncane kwendawo yokusebenza. Lokhu kungenxa yokuthi ungqimba olungaphezulu kuphela olushiselwayo, kuyilapho umongo uhlala upholile, unciphisa ukucindezeleka okushisayo nokuguquka.

C. Ukumelana nokugqokwa okuthuthukisiwe

Isendlalelo esingaphezulu esiqinile esizuzwe ngokuqina kokungeniswa sithuthukisa kakhulu ukumelana nokugqokwa kwengxenye. Lokhu kubaluleke kakhulu kumashafti namasilinda anobubanzi obukhulu angaphansi kwemithwalo ephezulu kanye nokungqubuzana phakathi nokusebenza.

D. Ukwandisa amandla okukhathala

Ukucindezelwa kwensalela okucindezelayo okudalwe ukupholisa okusheshayo phakathi nenqubo yokwenza lukhuni kokungeniswa kungathuthukisa amandla okukhathala kwengxenye. Lokhu kubalulekile ezinhlelweni zokusebenza lapho ukulayisha ngomjikelezo kuyinto ekhathazayo, njengasemishinini yezimoto neyezimboni.

IV. Inqubo Yokungeniswa Ukuqina

A. Izisetshenziswa

1. Isistimu yokushisa yokungeniswa

Isistimu yokushisisa ye-induction iqukethe ukunikezwa kwamandla, i-inverter ye-high-frequency, kanye nekhoyili yokungeniswa. Ukunikezwa kwamandla kunikeza amandla kagesi, kuyilapho i-inverter iwaguqulela kufrikhwensi oyifunayo. Ikhoyili yokungeniswa, ngokuvamile eyenziwe ngethusi, ikhiqiza inkambu kazibuthe eyenza ama-eddy currents endaweni yokusebenza.

2. Ukucisha uhlelo

Ngemuva kokuthi ungqimba olungaphezulu lushiselwe ekushiseni okufunayo, ukupholisa okusheshayo (ukucisha) kuyadingeka ukuze kuzuzwe i-microstructure oyifunayo nobulukhuni. Amasistimu okucisha angasebenzisa imidiya ehlukahlukene, njengamanzi, izixazululo ze-polymer, noma igesi (umoya noma i-nitrogen), kuye ngosayizi wengxenye kanye nejometri.

B. Amapharamitha okucubungula

I-1. Amandla

Izinga lamandla lesistimu yokushisa yokungeniswa linquma izinga lokushisa kanye nokujula kwekesi eliqinile. Amaleveli wamandla aphezulu aholela kumazinga okushisa asheshayo kanye nokujula kwekesi elijulile, kuyilapho amaleveli wamandla aphansi enikeza ukulawula okungcono futhi anciphise ukuhlanekezela okungaba khona.

2. Imvamisa

Ukuvama komsinga oshintshanayo ku- coil induction kuthonya ukujula kwecala eliqinile. Amafrikhwensi aphezulu aholela ekujuleni kwekesi elingashoni ngenxa yomphumela wesikhumba, kuyilapho amafrikhwensi aphansi engena ajule kokubalulekile.

3. Isikhathi sokushisa

Isikhathi sokushisisa sibalulekile ekufinyeleleni izinga lokushisa elifiswayo kanye ne-microstructure endaweni engaphezulu. Ukulawula okunembile kwesikhathi sokushisa kubalulekile ukuvimbela ukushisa ngokweqile noma ukushisa okungaphansi, okungaholela ezintweni ezingathandeki noma ukuphazamiseka.

4. Indlela yokucisha

Indlela yokucisha idlala indima ebalulekile ekunqumeni i-microstructure yokugcina kanye nezakhiwo zendawo eqinile. Izinto ezifana nokucisha okuphakathi, izinga lokugeleza, nokufana kokufakwa kufanele kulawulwe ngokucophelela ukuze kuqinisekiswe ukuqina okungaguquguquki kuyo yonke ingxenye.

V. Izinselelo Ezinezici Zobubanzi Obukhulu

A. Ukulawula izinga lokushisa

Ukuzuza ukusatshalaliswa kwezinga lokushisa okufanayo endaweni yonke yezingxenye ezinobubanzi obukhulu kungaba inselele. Ama-gradients okushisa angaholela ekuqineni okungaguquki kanye nokuhlanekezela okungaba khona noma ukuqhekeka.

B. Ukuphathwa kokuhlanekezela

Izingxenye ezinobubanzi obukhulu zisengozini yokuhlanekezelwa ngenxa yobukhulu bazo kanye nokucindezeleka okushisayo okubangelwa ngesikhathi senqubo yokufaka ukuqina. Ukulungiswa okufanele kanye nokulawulwa kwenqubo kubalulekile ukuze kuncishiswe ukuhlanekezela.

C. Ukuqeda ukufana

Ukuqinisekisa ukucisha okufanayo kuyo yonke indawo yezingxenye ezinobubanzi obukhulu kubalulekile ukuze kuzuzwe ukuqina okungaguquki. Ukucisha okunganele kungabangela izindawo ezithambile noma ukusabalalisa ubulukhuni obungalingani.

VI. Amasu Okwenza Ukuqina Okuphumelelayo

A. Ukuthuthukiswa kwephethini yokushisisa

Ukuthuthukisa iphethini yokushisisa kubalulekile ukuze kuzuzwe ukuqina okufanayo ezingxenyeni ezinobubanzi obukhulu. Lokhu kungenziwa ngokuklama ikhoyili ngokucophelela, ukulungiswa kwemvamisa yokungeniswa kanye namazinga wamandla, kanye nokusetshenziswa kwezindlela ezikhethekile zokuskena.

B. Idizayini yekhoyili yokungeniswa

Idizayini yekhoyili yokungeniswa idlala indima ebalulekile ekulawuleni iphethini yokushisisa nokuqinisekisa ukuqina okufanayo. Izinto ezifana ne-coil geometry, ukuminyana kokuphenduka, kanye nokuma okuhlobene nendawo yokusebenza kufanele kubhekwe ngokucophelela.

C. Ukucisha ukukhethwa kwesistimu

Ukukhetha isistimu yokucisha efanelekile kubalulekile ukuze kuqiniswe ngempumelelo izingxenye ezinobubanzi obukhulu. Izinto ezifana nokucisha okuphakathi, izinga lokugeleza, nendawo yokumbozwa kufanele kuhlolwe ngokusekelwe kusayizi wengxenye, ijiyomethri, nezinto ezibonakalayo.

D. Ukuqapha nokulawula inqubo

Ukusebenzisa izinhlelo eziqinile zokuqapha nokulawula kubalulekile ukuze kuzuzwe imiphumela engaguquki nephindaphindekayo. Izinzwa lokushisa, ukuhlolwa kokuqina, kanye nezinhlelo zempendulo ye-close-loop kungasiza ukugcina amapharamitha enqubo ngaphakathi kwebanga elamukelekayo.

VII. Izinhlelo zokusebenza

A. Shafts

1. Izithuthi

Ukuqina kwe-induction kusetshenziswa kakhulu embonini yezimoto ukwenza lukhuni amashafu anobubanzi obukhulu ezinhlelweni ezinjengama-driveshaft, ama-axles, nezinto zokudlulisa. Lezi zingxenye zidinga ukumelana nokugqoka okuphezulu namandla okukhathala ukuze zimelane nezimo zokusebenza ezinzima.

2. Imishini yezimboni

Amashafu anobubanzi obukhulu nawo ajwayele ukuqina kusetshenziswa ukuqina kokungeniswa emishinini eyahlukene yezimboni, njengezinhlelo zokudlulisa amandla, izigayo eziginqikayo, kanye nemishini yezimayini. Indawo eqinile iqinisekisa ukusebenza okuthembekile nokuphila kwesevisi okwandisiwe ngaphansi kwemithwalo esindayo kanye nezindawo ezinzima.

B. Amasilinda

1. Amanzi

Amasilinda angama-hydraulic, ikakhulukazi lawo anobubanzi obukhulu, azuza ekuqinisweni kwe-induction ukuze kuthuthukiswe ukumelana nokugqokwa nokwelula impilo yesevisi. Indawo eqinile inciphisa ukuguga okubangelwa uketshezi olunomfutho ophezulu kanye nokuxhumana okuslayidayo nama-seal namapiston.

2. I-pneumatic

Ngokufanayo namasilinda amanzi, amasilinda womoya wobubanzi obukhulu asetshenziswa ezinhlelweni ezihlukene zezimboni angenziwa abe nzima ukuze kuthuthukiswe ukuqina kwawo kanye nokumelana nokugqokwa okubangelwa umoya ocindezelwe kanye nezingxenye ezishelelayo.

VIII. Ukulawula Ikhwalithi Nokuhlola

A. Ukuhlolwa kokuqina

Ukuhlolwa kokuqina kuyisilinganiso esibalulekile sokulawula ikhwalithi ekuqiniseni i-induction. Izindlela ezehlukene, ezifana ne-Rockwell, Vickers, noma ukuhlolwa kokuqina kwe-Brinell, zingasetshenziswa ukuze kuqinisekiswe ukuthi indawo eqinile ihlangabezana nezidingo ezishiwo.

B. Ukuhlaziywa kwe-Microstructural

Ukuhlolwa kwe-Metallographic kanye nokuhlaziywa kwe-microstructural kunganikeza imininingwane ebalulekile ngekhwalithi yecala eliqinile. Amasu afana ne-optical microscopy kanye ne-electron microscopy yokuskena angasetshenziswa ukuhlola i-microstructure, ukujula kwekesi, kanye nokukhubazeka okungenzeka.

C. Isilinganiso sokucindezeleka esisalela

Ukulinganisa izingcindezi eziyinsalela endaweni eqinile kubalulekile ekuhloleni amandla okuhlanekezela nokuqhekeka. I-X-ray diffraction kanye nezinye izindlela ezingabhubhisi zingasetshenziswa ukukala izingcindezi ezinsalela futhi kuqinisekiswe ukuthi zingaphakathi kwemikhawulo eyamukelekayo.

IX. Isiphetho

A. Isifinyezo samaphuzu abalulekile

Ukuqina kwe-induction kuyinqubo ebalulekile yokuthuthukisa izakhiwo ezingaphezulu zamashafu namasilinda anobubanzi obukhulu. Ngokukhetha ukuqinisa ungqimba olungaphezulu, le nqubo ithuthukisa ukumelana nokugqokwa, amandla okukhathala, nokuqina kuyilapho igcina ukudumba nokuqina kwento esemqoka. Ngokulawula ngokucophelela imingcele yenqubo, ukwakheka kwamakhoyili, kanye nezinhlelo zokucisha, imiphumela engaguquki futhi ephindaphindwayo ingafinyelelwa kulezi zingxenye ezibalulekile.

B. Amathrendi nentuthuko yesikhathi esizayo

Njengoba izimboni ziqhubeka nokufuna ukusebenza okuphezulu nempilo yesevisi ende ezingxenyeni ezinobubanzi obukhulu, kulindeleke ukuthi kuthuthuke ubuchwepheshe bokwenza ukuqina kwe-induction. Intuthuko ezinhlelweni zokuqapha nokulawula izinqubo, ukwenziwa ngcono kwedizayini yamakhoyili, kanye nokuhlanganiswa kwamathuluzi okulingisa nawokumodela kuzothuthukisa ukusebenza kahle kanye nekhwalithi yenqubo yokufaka ukuqina kwe-induction.

I-Q1: Iluphi ububanzi obujwayelekile bobulukhuni obufinyelelwa ngokufakwa ukuqina kwezingxenye ezinobubanzi obukhulu?

I-A1: Ububanzi bobulukhuni obuzuzwa ngokuqiniswa kokungeniswa buncike ezintweni kanye nesicelo esidingekayo. Ezinsimbi, amanani okuqina ngokuvamile asukela ku-50 kuya ku-65 HRC (i-Rockwell Hardness Scale C), enikeza ukumelana nokugqokwa okuhle kakhulu namandla okukhathala.

I-Q2: Ingabe ukuqina kokungeniswa kungasetshenziswa ezintweni ezingezona insimbi?

A2: Ngenkathi ukuqina kokungeniswa isetshenziselwa ikakhulukazi izinto ezisansimbi (izinsimbi nezinsimbi ezisansimbi), ingasetshenziswa futhi ezintweni ezithile ezingenayo insimbi, njengama-alloys asekelwe ku-nickel kanye nama-titanium alloys. Kodwa-ke, izindlela zokushisa kanye nemingcele yenqubo ingase ihluke kuleyo esetshenziselwa izinto ezinsimbi.

I-Q3: Inqubo yokwenza ukuqina kwe-induction ithinta kanjani izakhiwo eziyinhloko zengxenye?

I-A3: Ukwenza lukhuni kwe-induction ngokukhetha kwenza ungqimba olungaphezulu lube lukhuni ngenkathi kushiya okubalulekile kungathinteki. I-core igcina i-ductility yayo yasekuqaleni kanye nokuqina, ihlinzeka ngenhlanganisela efiselekayo yobulukhuni bendawo namandla awo wonke kanye nokumelana nomthelela.

I-Q4: Yiziphi imidiya yokucisha ejwayelekile esetshenziselwa ukuqina kokufakwa kwezingxenye ezinobubanzi obukhulu?

I-A4: Imidiya yokucisha evamile yezingxenye ezinobubanzi obukhulu ihlanganisa amanzi, izixazululo ze-polymer, negesi (umoya noma i-nitrogen). Ukukhethwa kwendawo yokucisha kuncike ezintweni ezifana nosayizi wengxenye, ijiyomethri, nezinga lokupholisa elifunekayo kanye nephrofayela yokuqina.

I-Q5: Ngabe ukujula kwecala eliqinile kulawulwa kanjani ukuqina kokungeniswa?

I-A5: Ukujula kwecala eliqinile kulawulwa ngokuyinhloko ngokulungisa imvamisa yokungeniswa kanye namazinga wamandla. Amafrikhwensi aphezulu aholela ekujuleni kwecala elingashoni ngenxa yomphumela wesikhumba, kuyilapho amafrikhwensi aphansi avumela ukungena okujulile. Ukwengeza, isikhathi sokushisisa nezinga lokupholisa kungase kube nomthelela ekujuleni kwekesi.