Induction Ukuphulukisa Ukushisa kwe-Coal Coating

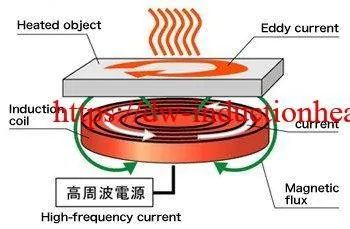

Ukushisa Ukushisa isetshenziselwa ukwelapha izigqoko eziphilayo ezifana nopende emagcekeni ensimbi ngokudala ukushisa ngokukhipha. Lokhu kusho ukuphulukisa okuvela ngaphakathi ngaphakathi ekunciphiseni ukuthambekela kokwakhiwa kweziphambeko zokugqoka. Okuvamile uhlelo lokusebenza loma ukudweba kwendwangu yeshidi.

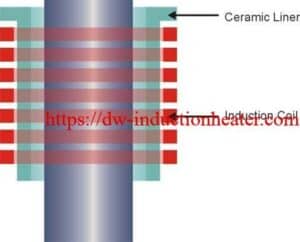

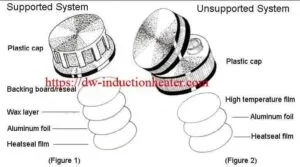

Ukushisa ukushisa kwezingxenye zensimbi ukunamathela ukuphulukiswa kokungeniswa amazinga okushisa asetshenziselwa izinqubo eziningi zezimoto, njengokusetshenziswa kwamathelethi okushisa ukukhiqiza amacwecwe ama-clutch, izicathulo zokuwasha kanye nezinsimbi ze-auto bumper. Izakhi zivame ukuboshwa ezikhathini ze-squirrel ekwakheni ama-motor amancane. Ekukopheni imishini, izingxenye zepulasitiki zihambisana nezibopho ze-aluminium; i-glue ye-thermoplastiki isetshenziselwa ukubamba ama-foam rollers ezakhiweni zensimbi. Uma ama-rollers ephela, i-shaft iyashisa futhi i-foam ishintshiwe.

Modern Ukushisa ukufakelwa ingaxazulula eziningi zalezi zinkinga. Ukushisa nge-induction kunikeza ukushisa okunokwethenjelwa, okuphindaphindiwe, okungaxhunyiwe nokusebenza kahle ngesikhathi esincane, ukuze inqubo yokuphulukisa ingagcwaliswa ngesikhashana namandla. Ukuthuthukiswa kokushisa kwezinga lokushisa kungaphumelela ngokulawulwa kwekhompyutheni yombuso oqinile wezinsiza. Ukuqeda izinyathelo ezingeziwe zokulayisha nokulayishwa kwama-ovens, iziteshi zokushisa zokufakelwa zingafakwa emgqeni wokukhiqiza. Okokugcina, ukushisa okufakelwayo kungenziwa ezindaweni ezihlanzekile kakhulu, izimo zokuphumula noma izakhiwo ezikhethekile, okuvumela ukuxazulula izixazululo eziyingqayizivele.

Nakuba ukushisa kwe-induction kuvame ukusetshenziswa ngezinsimbi noma ezinye izinto zokwenza izinto, amaplastiki nezinye izinto ezingekho ukuqhuba kahle ngokuvamile zivutha kakhulu ngokusebenzisa i-susceptor yensimbi ehamba phambili yokudlulisa ukushisa. Amandla e-RF ajwayelekile ukuphulukiswa kokungeniswa izinhlelo zokusebenza zisukela ku-4 kuye ku-60kW, kuya ngezingxenye nezidingo zohlelo lokusebenza.