I-Induction Soldering Board Circuit Ne-IGBT yokushisa uhlelo

Inhloso Ukushisa okuthunyelwe okuthunyelwe, okuholayo noma okungenakho ukuhola kwezicelo ezahlukahlukene zebhodi yesifunda.

Amabhodi wesifunda aphezulu nangaphansi, okuhola okuncane nokukhulu noma okuhola ama-preforms wamahhala.

Ithempelesha <700 ºF (371ºC) kuya nge-preform esetshenzisiwe

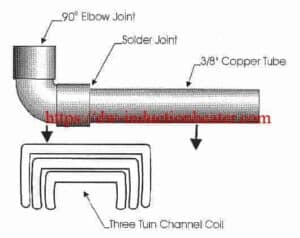

Ukuphindaphindwa kathathu vula ikhoyili ye-364 kHz

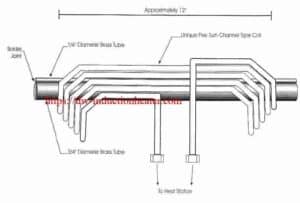

Ikhoyili encane encane ye-400 kHz

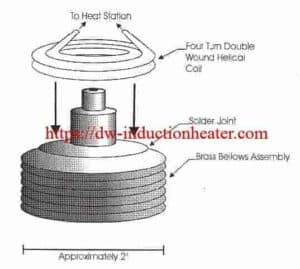

Ikhoyili enkulu yokujika ye-350 kHz

Izinsiza kusebenza

• Ikhoyili yokushisa yokungeniswa, yakhelwe futhi yathuthukiswa ngqo yalolu hlelo lokusebenza.

Inqubo Amakhoyili amathathu ngamanye asetshenziselwa ukufudumeza izindawo ezahlukahlukene ebhodini lesifunda kuye ngokuthi indawo leyo iyisicelo esisodwa noma uhlelo lweqembu. Isikhathi siyahluka kusuka kumasekhondi angu-1.8 kuye kwayi-7.5 kuye ngendawo. Ekhiqizweni iziteshi zokushisa namakhoyili zihanjiswa zibekwe ngaphezulu kweposi ngezinhloso ze-automation. Kusetshenziswa ama-preforms wokuhola noma wokuhola wamahhala. Isikhathi senqubo kwi-lead solder yamahhala sinde kancane.

Imiphumela / Izinzuzo Zokushisa Ukushisa inikeza:

• Ukushisa okungenazandla okungabandakanyi ikhono le-opharetha lokukhiqiza, kuzibophezela kahle ku-automation.

• I-Solder elawulwa yi-preforms, akukho okweqile okusele ebhodini.

• Ukugeleza okuhle kwe-solder ngaphandle kokushisa ibhodi nokulimaza amasekethe nezinto eziseduze.