Iyini i-heater ye-billet yokungeniswa yokwakhiwa kwe-billet eshisayo?

An ukukhishwa kwebhayisikili ebhalisiwe ucezu olukhethekile lwemishini esetshenziswa kwinqubo yokwakhiwa kwe-billet eshisayo. Isebenzisa ukungeniswa kwe-electromagnetic ukushisisa amabhilidi ensimbi ezingeni lokushisa elidingekayo lokubumba nokwenza.

Inqubo yokwakhiwa kwe-billet eshisayo iyisici esibalulekile embonini yokukhiqiza, lapho ukuguqulwa kwensimbi ibe yizimo ezihlukahlukene kanye nemikhiqizo kwenzeka. Ingxenye eyisisekelo yale nqubo ukushisa kwamabhilidi, okuyimigoqo emide, eqinile noma amabhlogo ensimbi. Indlela esetshenziswayo ukushisisa lawa mabhilidi ithinta kakhulu ukusebenza kahle, ikhwalithi, kanye nezindleko eziphelele zokukhiqiza. Kulapho ama-heaters e-induction billet eqala ukusebenza khona, ahlinzeka ngesixazululo sesimanjemanje, esisebenza kahle, nesinembayo. Kulesi sihloko esibanzi, sizohlola ubuchwepheshe be-induction billet heater, izinzuzo zabo, kanye nezicelo zabo embonini yokwenza ama-billet ashisayo.

Ngabe i-heater ye-induction billets isebenza kanjani?

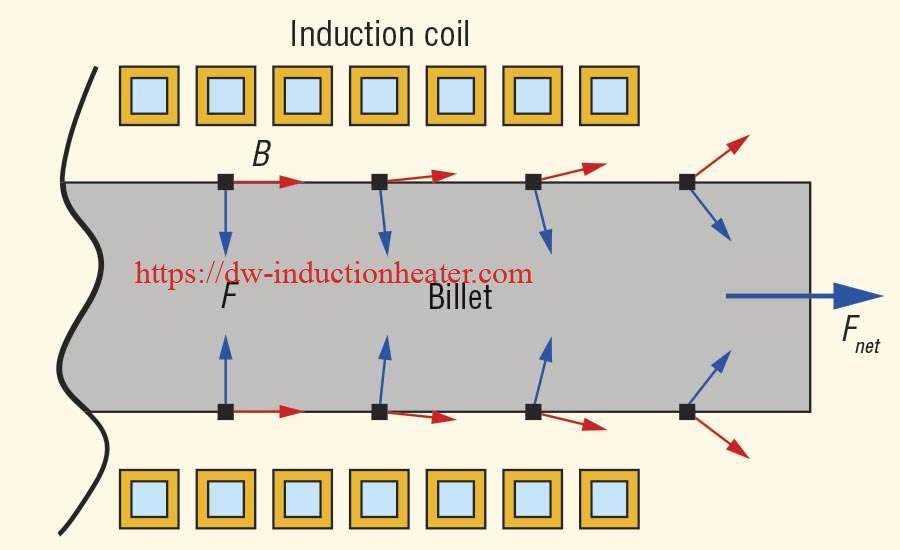

The ukukhishwa kwebhayisikili ebhalisiwe isebenza ngokusebenzisa inkambu ye-electromagnetic ukuze ikhiqize ukushisa ngaphakathi kwe-billet yensimbi. I-alternating current idlula ikhoyili, idale insimu kazibuthe. Le nkundla kazibuthe idala imisinga eddy ngaphakathi kwe-billet, iyenze ishise ngokushesha.

Ukubuka konke Kwezobuchwepheshe:

Ukubuka konke Kwezobuchwepheshe:

Ukushisa kokungeniswa kusekelwe kumgomo wokungeniswa kwe-electromagnetic, owatholwa nguMichael Faraday ngeminyaka yawo-1830. Kubandakanya ukukhiqiza ama-eddy currents ngaphakathi kwento eqhutshwayo, njenge-billet yensimbi, ngokuyifaka ngaphansi kwenkundla kazibuthe ehlukahlukene. Ukusebenzisana phakathi kwenkundla kazibuthe kanye nemisinga ye-eddy kukhiqiza ukushisa okuphikisayo ngaphakathi kwe-billet. I-heater ye-billet yokungeniswa ngokuvamile ihlanganisa ikhoyili yokungeniswa, ukunikezwa kwamandla, nesistimu yokulawula, konke okuklanyelwe ukushisisa amabhilidi ngokufanayo kuya ezingeni lokushisa olifunayo.

Izingxenye kanye nokusebenza:

1 Ikhoyili: I coil induction, ngokuvamile eyenziwe ngamashubhu ethusi, iyinhliziyo ye-heater billets. Iklanyelwe ukuthwala i-high-frequency alternating current (AC). Ukuma nosayizi wekhoyili kuhambisana nobukhulu bamabhilidi ukuze kuqinisekiswe ukushisa okusebenzayo. Uma i-billet ibekwe ngaphakathi noma eduze kwekhoyili, inkambu kazibuthe eshintshanayo ingenisa i-current ku-billet, idale ukushisa.

2. Ukunikezwa kwamandla: Ukunikezwa kwamandla kwe-heater ye-billet yokungeniswa kuyi-inverter eguqula amandla kagesi ukusuka kugridi kuya ku-AC ye-high-frequency edingekayo ngenqubo yokungeniswa. Izimpahla zamandla zanamuhla ziyakwazi ukuletha ububanzi obuhlukahlukene, okuvumela ukulawula okunembile phezu kwenqubo yokushisa.

2. Ukunikezwa kwamandla: Ukunikezwa kwamandla kwe-heater ye-billet yokungeniswa kuyi-inverter eguqula amandla kagesi ukusuka kugridi kuya ku-AC ye-high-frequency edingekayo ngenqubo yokungeniswa. Izimpahla zamandla zanamuhla ziyakwazi ukuletha ububanzi obuhlukahlukene, okuvumela ukulawula okunembile phezu kwenqubo yokushisa.

3. Isistimu Yokulawula: Isistimu yokulawula inesibopho sokulawula umjikelezo wokushisisa, ukuqapha izinga lokushisa, nokuqinisekisa ukuthi i-billet ishisa ngokulinganayo ekucacisweni okumisiwe. Lokhu ngokuvamile kufinyelelwa ngokusebenzisa izinzwa zezinga lokushisa, izihibe zempendulo, nesofthiwe ethuthukisiwe elungisa ukunikezwa kwamandla ngesikhathi sangempela.

Yiziphi izinzuzo zokusebenzisa i-induction billets heater?

Izishisi ze-induction billets zinikeza izinzuzo ezimbalwa kunezindlela zokushisisa zendabuko ezifana neziko legesi noma ama-oveni okumelana:

1. Ukusebenza kahle: Ukushisa ukushisa inamandla kakhulu, njengoba ukushisa kukhiqizwa ngokuqondile ngaphakathi kwe-billet ngaphandle kwesidingo se-medium yokudlulisa. Le ndlela yokushisa eqondile inciphisa ukulahlekelwa ukushisa futhi inganciphisa kakhulu ukusetshenziswa kwamandla.

2. Ukunemba: Ikhono lokulawula eduze amandla kanye nemvamisa ye-heater yokungeniswa ivumela ukulawula izinga lokushisa okunembile. Lokhu kubangela ukushisa okufanayo kwe-billet, okubalulekile ekugcineni izakhiwo ze-metallurgical zensimbi ngesikhathi sokwakheka.

2. Ukunemba: Ikhono lokulawula eduze amandla kanye nemvamisa ye-heater yokungeniswa ivumela ukulawula izinga lokushisa okunembile. Lokhu kubangela ukushisa okufanayo kwe-billet, okubalulekile ekugcineni izakhiwo ze-metallurgical zensimbi ngesikhathi sokwakheka.

3. Isivinini: Ukushisa kokungeniswa kungashesha kakhulu kunezindlela zendabuko, njengoba ukushisa kukhiqizwa cishe ngokushesha ngaphakathi kwe-billet. Lokhu kunciphisa izikhathi zomjikelezo futhi kwandisa ukuphuma.

4. Ukuphepha: Njengoba ukushisisa kwe-induction kungancikile ekushisweni, kuveza izingozi zokuphepha ezimbalwa kunokushisa okusekelwe elangabini. Ukungabi bikho kwamalangabi nokuncishiswa kwesisi esingcolisa umoya kunomthelela endaweni yokusebenza ephephile nehlanzekile.

5. Ukuvumelana nezimo: Izishisi ze-billet zokungeniswa zingaklanywa ukuze zithwale uhla lwamasayizi we-billet nokuqanjwa, okuzenze zifanelekele izinhlelo zokusebenza ezihlukahlukene ngaphakathi komkhakha wokwenza insimbi.

Yiziphi izinhlobo zebhilidi ezingashiswa kusetshenziswa i-heater yebhilidi yokungeniswa?

Isingeniso se-billets heater ingasetshenziselwa ukushisisa amabhilidi ensimbi amaningi, okuhlanganisa insimbi, i-aluminium, ithusi, namanye ama-alloys. Usayizi nokuma kwamabhilidi kungahluka, futhi i-heater yokungeniswa ingenziwa ngokwezifiso ukuze ihambisane nezidingo ezithile.

Izicelo Ekufomeni kwe-Hot Billet:

Izicelo Ekufomeni kwe-Hot Billet:

Isingeniso se-billets heater baqashwe ezinqubweni ezehlukene zokwenza ama-billet ashisayo, okuhlanganisa ukufoja, ukukhipha, nokugingqika. Ekwenziweni, amabhilidi ashisayo akhubazekile phakathi kwama-dies ukuze akhe izimo eziyinkimbinkimbi. Ku-extrusion, amabhilidi ashisayo aphoqelelwa ngefa ukuze adale imikhiqizo emide enezigaba ezifanayo. Ukugingqa kuhilela ukudlulisa i-billet eshisayo ochungechungeni lwemiqulu ukuze kuzuzwe umumo nogqinsi olufunekayo.

Izifudumezi zebhilidi yokungeniswa zimelela intuthuko ebalulekile emkhakheni wokwakhiwa kwe-billet eshisayo. Ikhono labo lokuletha ukushisa okusebenzayo, okunembayo, nokusheshayo libenze babaluleke kakhulu ekusethweni kwesimanje kokukhiqiza. Ngokugxila okuqhubekayo ekusebenzeni kahle kwamandla kanye nokwenza kahle kokukhiqiza, indima yokushisisa okungeniswayo embonini yensimbi isethelwe ukunwetshwa ngokuqhubekayo, iqhubekisele phambili ukuqamba okusha kanye nekhwalithi ezinqubweni zokukhiqiza zesikhathi esizayo.