Ukuxubha Ukuxubha Isixhumi Sebhusi Esigabeni Solar With Heater Heater

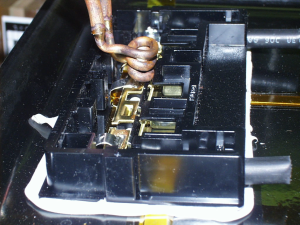

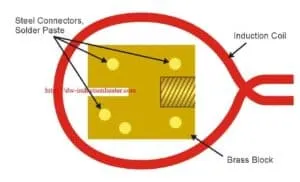

I-Objective Solder izixhumi zethusi ezintathu ngasikhathi sinye ebhokisini lokuhlangana kwephaneli yelanga ngaphandle kokuthinta izingxenye zebhokisi lokuhlangana.

Izinto ebhokisini lebhola lebhokisi lokuhlangana, izixhumi zethusi, ucingo lwe-solder

Ukushisa 700 ºF (371 ºC)

I-Frequency 344 kHz

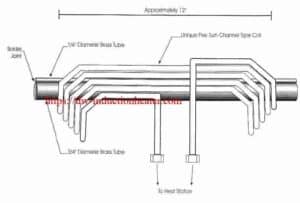

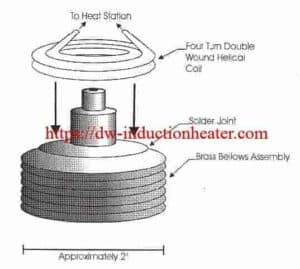

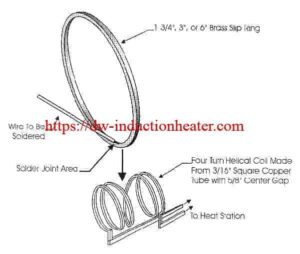

Izinsiza kusebenza • Uhlelo lwe-DW-UHF-6 kW lokushisa lokungeniswa, olunekhanda lokusebenza elikude eliqukethe i-1.0 μF capacitor eyodwa.

• Ikhoyili yokushisa yokungeniswa eyenzelwe futhi yathuthukiswa ngqo yalolu hlelo lokusebenza.

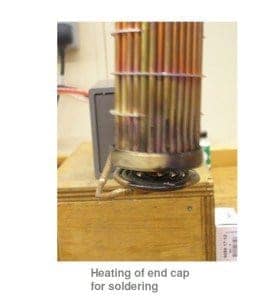

Inqubo Kusetshenziswa ikhoyili ye-helical emise okweqanda ezintathu ukushisa izixhumi. Ucezu lwentambo ye-solder lubekwa endaweni ehlanganisiwe futhi ilunga ngalinye lifudunyezwa ngokwehlukana imizuzwana emi-5 ukuxhuma isixhumi. Isikhathi senqubo esiphelele yimizuzwana eyi-15 yamajoyinti amathathu.

Imiphumela / Izinzuzo Zokushisa Ukushisa inikeza:

• Ukunemba kokukhomba kuletha ukushisa kuhlangothini kuphela; akuthinti izinto ezizungezile

• Ukushisa kwendawo kuveza amalunga ahlanzekile futhi ahlanzekile

• Iveza izinga eliphezulu, imiphumela ephindaphindiwe

• Ngisho nokusatshalaliswa kokushisa