Enye yentuthuko evelele yakamuva emkhakheni wokwelapha ukushisa kube ukusetshenziswa kwe Ukushisa ukufakelwa ukuqina kwendawo yendawo. Intuthuko eyenziwe ngokuncikene nokusetshenziswa kwe-high frequency current ibe yinto enhle kakhulu. Ukuqala esikhathini esifushane kakhulu esidlule njengendlela ekade ifunwa ukuqinisa izindawo ezithwalayo kuma-crankshafts (izigidi ezimbalwa zazo zisetshenziswa ukusetha amarekhodi esevisi yesikhathi sonke), namuhla ithola le ndlela ekhetha kakhulu yokwenza lukhuni okungaphezulu ikhiqiza izindawo eziqinile ngobuningi izingxenye. Nokho, naphezu kobubanzi bayo bosuku lwanamuhla, ukuqina kokungeniswa kusesesigabeni sako sosana. Ukusetshenziselwa kwayo okungaba khona ekwelapheni ukushisa kanye nokwenza lukhuni kwezinsimbi, ukushisisa ukufojwa noma ukubhula, noma ukusoda kwezinsimbi ezifanayo nezingafani, akubikezeleki.

Ukuqeda ukuqina kuholela ekukhiqizweni kwezinto zensimbi eziqinile endaweni enezinga elifiselekayo lokujula nobulukhuni, ukwakheka kwensimbi ebalulekile komnyombo, indawo yokuklama, kanye nekesi eliqinile, ngokuntula okungokoqobo kokuhlanekezela kanye nokwakheka kwesikali. Ivumela ukwakhiwa kwemishini egunyaza ukwenziwa ngemishini kwawo wonke umsebenzi ukuze kufezwe izidingo zomugqa wokukhiqiza. Imijikelezo yesikhathi yamasekhondi ambalwa kuphela igcinwa ngokuzenzakalelayo ukulawula amandla kanye nezikhawu ezihlukanisayo zokushisisa kanye nokucisha okudingekayo ekudalweni kwemiphumela yefeksi yokufuna ukulungiswa okukhethekile. Okokusebenza kokuqina kwe-induction kuvumela umsebenzisi ukuthi aqinise phezulu kuphela ingxenye edingekayo yanoma iyiphi into yensimbi futhi ngaleyo ndlela agcine ukudubeka namandla kwangempela; ukwenza lukhuni izinto zomklamo oyinkimbinkimbi ongeke waphathwa nganoma iyiphi enye indlela; ukuqeda ukwelashwa okuvamile okumba eqolo okufana ne-copper plating kanye nokungcwatshwa kwe-carburizing, kanye nemisebenzi ebizayo elandelayo yokuqondisa nokuhlanza; ukunciphisa izindleko zempahla ngokuba nezinhlobo eziningi zezinsimbi ongakhetha kuzo; kanye nokwenza lukhuni into eyenziwe ngomshini ngokugcwele ngaphandle kwesidingo sanoma yimiphi imisebenzi yokuqeda.

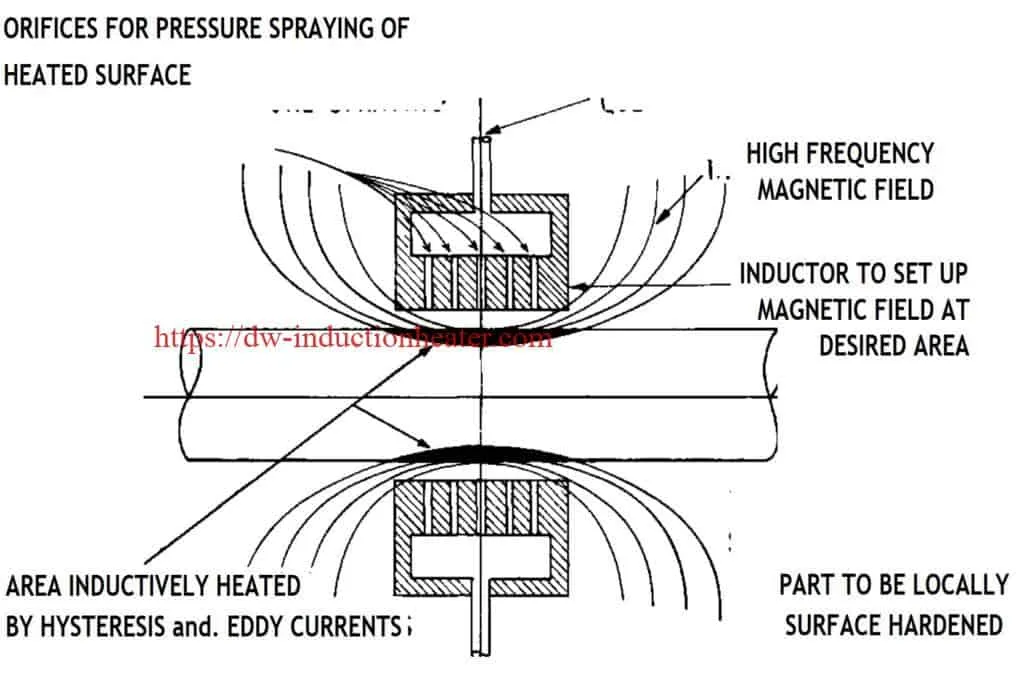

Kumbukeli ovamile kungase kubonakale sengathi ukuqina kokungeniswa kungenzeka ngenxa yoshintsho oluthile lwamandla olwenzeka ngaphakathi kwendawo yethusi eguquguqukayo. Ikhopha ithwala amandla kagesi wefrikhwensi ephezulu futhi, phakathi nesikhawu samasekhondi ambalwa, indawo engaphezulu yensimbi ebekwe ngaphakathi kwalesi sifunda esinamandla iyashisisa ifike ebangeni layo elibucayi futhi icime kuze kube ukuqina okukhulu. Kumkhiqizi wezinto zokusebenza zale ndlela yokuqinisa kusho ukusetshenziswa kwezenzakalo ze-hysteresis, ama-eddy currents, nomphumela wesikhumba ekukhiqizeni okuphumelelayo kokuqina kwendawo yendawo.

Ukushisa kwenziwa ngokusebenzisa amaza omoya aphezulu. Amafrikhwensi akhethiwe asuka ku-2,000 kuye kwayizi-10,000 nemijikelezo engaphezu kuka-100 asetshenziswa kakhulu kulesi sikhathi samanje. Okwamanje yalolu hlobo ekugelezeni ku-inductor kukhiqiza inkambu kazibuthe enemvamisa ephezulu ngaphakathi kwesifunda se-inductor. Lapho izinto zikazibuthe ezifana nensimbi zifakwa ngaphakathi kwale nsimu, kuba nokuchitheka kwamandla ensimbi ekhiqiza ukushisa. Ama-molecule angaphakathi kwensimbi azama ukuziqondanisa ne-polarity yalo mkhakha, futhi ngalokhu kushintsha izikhathi eziyizinkulungwane ngomzuzwana, inani elikhulu lokungqubuzana kwamangqamuzana angaphakathi liyathuthukiswa ngenxa yokuthambekela kwemvelo kwensimbi ukumelana nezinguquko. Ngale ndlela amandla kagesi aguqulwa, phakathi nendawo yokungqubuzana, abe ukushisa.

Kodwa-ke, njengoba esinye isici esingokwemvelo se-high frequency current ukugxila phezu kwe-conductor yayo, izingqimba zangaphezulu kuphela ezifudumalayo. Lokhu kuthambekela, okubizwa ngokuthi "umphumela wesikhumba", kuwumsebenzi wokuphindaphinda futhi, ezinye izinto zilingana, amafrikhwensi aphezulu asebenza kahle ekujuleni okungashoni. Isenzo sokungqubuzana esikhiqiza ukushisa sibizwa ngokuthi i-hysteresis futhi ngokusobala sincike kuzimfanelo kazibuthe zensimbi. Ngakho-ke, lapho izinga lokushisa selidlulile iphuzu elibalulekile lapho insimbi iba yi-non-magnetic, konke ukushisa kwe-hysteretic kuyayeka.

Kunomthombo owengeziwe wokushisa ngenxa yama-eddy currents ageleza ensimbi ngenxa yokushintshashintsha ngokushesha ensimini. Ngokuphikiswa kwensimbi okwandayo ngezinga lokushisa, ukuqina kwalesi senzo kuyehla njengoba insimbi ishisa, futhi iyingxenyana kuphela yenani layo lokuqala "elibandayo" lapho izinga lokushisa elifanele lokucisha lifinyelelwa.

Lapho izinga lokushisa lensimbi eshisisa nge-inductively lifika endaweni ebucayi, ukushisa ngenxa yama-eddy currents kuqhubeka ngenani elinciphe kakhulu. Njengoba sonke isenzo siqhubeka ezingqimbeni ezingaphezulu, leyo ngxenye kuphela ethintekayo. Izakhiwo zokuqala eziwumgogodla ziyagcinwa, ukuqina kwendawo kwenziwa ngokucisha lapho isixazululo esiphelele se-carbide sesitholakele ezindaweni ezingaphezulu. Ukusetshenziswa okuqhubekayo kwamandla kubangela ukwanda kokuqina kokuqina, ngoba njengoba ungqimba ngalunye lwensimbi ilethwa ezingeni lokushisa, ukuminyana kwamanje kushintshela kungqimba olungaphansi olunikeza ukumelana okuphansi. Kusobala ukuthi ukukhethwa kwefrikhwensi efanele, nokulawulwa kwamandla nesikhathi sokushisa kuzokwenza ukugcwaliseka kwanoma yiziphi izincazelo ezifiselekayo zokuqiniswa kwendawo kungenzeka.

I-Metallurgy ye Ukushisa Ukushisa

Ukuziphatha okungavamile kwensimbi lapho kushiswa nge-inductively futhi imiphumela ithole ifanele ukuxoxisana nge-metallurgy ehilelekile. Amazinga esixazululo se-Carbide angaphansi kwesekhondi, ubulukhuni obuphakeme kunalowo okhiqizwa ukwelashwa kwesithando somlilo, kanye nohlobo lwe-nodular martensite amaphuzu okucatshangelwa.

ezihlukanisa i-metalurgy yokuqina kokungeniswa njengokuthi "okuhlukile". Ngaphezu kwalokho, ukususwa kwe-carburization ebusweni nokukhula kokusanhlamvu akwenzeki ngenxa yomjikelezo wokushisisa omfushane.

Ukushisa ukushisa ikhiqiza ubulukhuni obugcinwa ngamaphesenti angama-80 wokujula kwayo, futhi ukusuka lapho kuqhubeke, ukwehla kancane kancane endaweni yoguquko kuya ebulukhunini bangempela bensimbi njengoba kutholakala kumongo ongazange uthintwe. Ngakho-ke isibopho sifanelekile, sisusa noma yimaphi amathuba okukhipha noma ukuhlola.

Isixazululo esiphelele se-carbide kanye ne-homogeneity njengoba kufakazelwa ubulukhuni obukhulu kungafezwa ngesikhathi sokushisa esiphelele sesekhondi elingu-0.6. Ngalesi sikhathi, isekhondi elingu-0.2 kuye ku-0.3 kuphela elingaphezu kwesibucayi esiphansi. Kuyathakazelisa ukuqaphela ukuthi imishini yokuqinisa i-induction isebenza nsuku zonke ngesisekelo sokukhiqiza ngesisombululo esiphelele se-carbide, esibangelwa umjikelezo wokushisa nokucisha, isikhathi esiphelele esingaphansi kwesekhondi elingu-0.2.

I-martensite enhle eneziqhumane kanye ne-homogeneous more ewumphumela wokuqina kokungeniswa ibonakala kalula ngezinsimbi ze-carbon kune-alloy steel ngenxa yokubukeka kwe-nodular ye-alloy martensite eminingi. Lesi sakhiwo esihle kufanele sibe nemvelaphi yaso i-austenite okuwumphumela wokusabalalisa kwe-carbide okuphelele kunalokho okutholakala ngokushisa okushisayo. Ukuthuthuka ngokushesha kwamazinga okushisa abucayi kuyo yonke i-microstructure ye-alpha iron kanye ne-iron carbide kulungele ikakhulukazi isixazululo se-carbide esheshayo kanye nokusatshalaliswa kwezakhi onomkhiqizo wazo ongenakugwenywa i-austentite efana ne-homogeneous. Ngaphezu kwalokho, ukuguqulwa kwalesi sakhiwo sibe yi-martensite kuzokhiqiza i-martensite enezici ezifanayo kanye nokumelana okuhambisanayo kokugqokwa noma amathuluzi angenayo.

ukushisa ngesivinini esikhulu ngokungeniswa