Ukonga amandla ku lokungeniswa omiswe okusanhlamvu ngendlela yokushisa yokungeniswa

Ngonyaka iKazakhstan ikhiqiza cishe amathani ayizigidi eziyi-17-19 okusanhlamvu ngesisindo esihlanzekile, ithumela kwamanye amazwe cishe amathani ayizigidi ezi-5 okusanhlamvu, futhi umthamo omaphakathi wokusetshenziswa kwasekhaya ufinyelela kumathani ayizigidi eziyi-9-11. Ukuthuthuka okuqhubekayo komkhakha wokusanhlamvu nokukhuthaza ukuthunyelwa kwezinhlamvu okusanhlamvu kudinga ukuthuthukiswa kwengqalasizinda yokugcina, ukuhambisa kanye nokomisa okusanhlamvu, kufaka phakathi ukwakhiwa nokwakhiwa kabusha kwamasilo amadala okusanhlamvu, ukwakhiwa kwamatheminali echweba nokuthengwa kwemikhumbi yezimpahla eyomile kanye nabathwali bezinhlamvu (Baum, 1983). Kunesidingo sokwenza imboni ibe yesimanjemanje futhi umsebenzi udinga imizamo eqinile yombuso nabakhiqizi bezinhlamvu zikazwelonke.

Abahlanganyeli be-Astana Kazakh Grain Forum V KAZGRAIN-2012 baxoxe ngesimo samanje semakethe yezinhlamvu, izitayela kanye nokulindelwa kwentengo, kanye nezinkinga eziyinselele kulungiselelo lwezinto zokusebenza kanye nengqalasizinda. Kwaphawulwa ukuthi eminyakeni eyi-10 eyedlule iKazakhstan ibingathathwa njengomuntu othumela okusanhlamvu kwamanye amazwe, ngenkathi esikhathini samanje izindaba zokuthekelisa zithathwa njengezihamba phambili. Futhi ukukhiqizwa nokumiswa kokusanhlamvu kuthatha enye yezindawo ezihamba phambili zombili kwezolimo, kanye nomnotho wonkana.

Ukuhlaziywa kokuhlangenwe nakho kwamabhizinisi amaningi okukhiqiza ekusetshenzisweni kokudla okusanhlamvu emva kokuvunwa kufakazela ukuthi umsebenzi oyinhloko ekuqinisekiseni ukuphepha nekhwalithi yezinhlamvu ezintsha ezisanda kuvunwa yokomiswa kwazo. Ukubaluleka kokumiswa kokusanhlamvu kuyanda endaweni enomswakama: ukubambezeleka ukomiswa noma ukwenza lo msebenzi ngokwephula imibuso yezobuchwepheshe nakanjani kudale ukulahleka kwezitshalo. Ngokocwaningo olwenziwe ku-25-28% umswakama wenqwaba izinsuku ezintathu ukuhluma kwehla ngo-20%. Futhi ukulahleka kwezinto ezomile kwenza u-0.7-1% ngosuku lapho umswakama wenqwaba yamabele ungama-37% (Ginzburg, 1973).

Izici ezibalulekile ekusetshenzisweni kahle kwama-dryer kwezolimo ukuhlinzekwa kwekhwalithi ephezulu yokusanhlamvu, ukukhuphuka komkhawulokudonsa kwamayunithi, kanye nokwehlisa izindleko zamandla. Isisekelo sokwenza ngcono ukusebenza kwama-dryers akhona kwezolimo ukuqinisekisa ukususwa okwanele nokuzinzile komswakama kusuka ku-cubic meter eyodwa kumakhamera ezomisi zokusanhlamvu. Esinye sezizathu zokuvimbela lokhu ukuthi amayunithi okupholisa, akhelwe kushaft yokomisa, awenzi izimo ezifanele zokupholisa okusanhlamvu okugcwele futhi ngaleyo ndlela anciphise ivolumu elisebenzayo le-shaft yokomisa nokususwa komswakama kumitha engama-cubic yekhamera.

Kusukela ukukhiqizwa kukakolweni ngo-2010 kukhombisa ukukhula okuzinzile okuzinzile: indawo yezitshalo inyuke ngo-17%, isivuno sikhuphuke ngama-25%, nesivuno esiphelele - ngama-52%. Ngo-1 Januwari ngo-2012 iKazakhstan ibinamasilo angama-258 anomthamo wokugcina amathani ayizinkulungwane eziyi-14 771.3 namakheshi anamandla okugcina amathani ayizinkulungwane eziyi-14 127.8. Ukwanda kwesivuno nokuvuna okuphelele kudinga ukuthuthukiswa kobuchwepheshe bokomisa ukugwema ukulahleka kwezitshalo nokugcina ikhwalithi yokusanhlamvu.

Indlela yokubuka kakhulu yokusula okusanhlamvu nokususa umswakama yi- indlela yokushisa engenayo okuhlala kufundwe okuncane futhi kungasetshenziswa kakhulu ekusebenzeni ngenxa yokungapheleli okukhulu kubuchwepheshe bokukhiqizwa kwama-frequency frequency. Yize i- imishini yokushisa yokufakelwa umkhiqizo njengamanje uyathuthukisa futhi ukuwusebenzisa umkhuba wokomisa okusanhlamvu kuya kuba ngcono kakhulu uma kuqhathaniswa nezindlela zokushisa zendabuko (iZhidko, 1982).

Okwamanje ukushisa kwe-induction kusetshenziselwa ukuqina komhlaba kwemikhiqizo yensimbi, ngokushisa kwe-deformation yepulasitiki (ekwakheni, ekugxivizeni, ekucindezeleni, njll.), Ukuncibilika kwensimbi, ukwelashwa kokushisa (ukuqinisa, ukufuthelana, ukujwayela, ukucima), i-welding, i-welding, i-soldering , izinsimbi. Ukushisa kwe-induction okungaqondile kusetshenziselwa ukufudumeza imishini yezobuchwepheshe (amapayipi, amathangi, njll.), Ukushisa oketshezi, ukomiswa kwamajazi nezinto zokwakha (isib., Ukhuni). Ipharamitha ebaluleke kakhulu yokufakwa kokushisa kwe-induction imvamisa. Ngenqubo ngayinye (ukuqina kobuso, ngokushisa) kukhona ibanga elihle lemvamisa, elihlinzeka ngokusebenza okuhle kakhulu kwezobuchwepheshe nakwezomnotho. Imvamisa esukela ku-50Hz iye ku-5 MHz isetshenziselwa ukufudumeza kokungeniswa.

Izinzuzo zokushisa kwe-induction zifaka okulandelayo:

- Ukudluliselwa kwamandla kagesi ngqo emzimbeni wokufudumeza kuvumela ukusebenzisa ukushisa okuqondile kwezinto, ngaleyo ndlela isilinganiso sokushisa sinjalo

- Ukudluliselwa kwamandla kagesi ngqo emzimbeni wokushisa akudingi amadivayisi wokuxhumana. Lokhu kuyasiza kulayini ozenzakalelayo

- Lapho okokushisa kungu-dielectric, isb okusanhlamvu, khona-ke amandla asatshalaliswa ngokulinganayo kulo lonke ivolumu yento yokushisa. Ngenxa yalokho, le ndlela yokungenisa inikeza ukushisa okusheshayo kwe

- Ukushisa kwe-induction ezimweni eziningi kungakhuphula umkhiqizo futhi kuthuthukise izimo zokusebenza. Idivayisi yokungeniswa ingathathwa njengohlobo lwesiguquli, lapho i-winding eyinhloko (i-inductor) ixhunywe kumthombo wamandla we-AC, futhi okokushisa kusebenza njengesibili

Ukwehliswa kwezindleko zakho konke ukufakwa kudinga ukuthuthukiswa kanye nokuqaliswa kokulula kokushisa kwe-design induction.

Umehluko omkhulu phakathi kokushisa kwe-induction kusuka ezindleleni zendabuko zokomiswa kulele ekushiseni kwe-volumetric. Ukushisa kungena kumkhiqizo (okokusebenza) hhayi ebusweni; yakhiwa kulo lonke ivolumu ngasikhathi sinye, le nqubo ivumela ukomisa okusanhlamvu ngempumelelo ngokusetshenziswa kwamandla aphansi. Ngisho nokusatshalaliswa komswakama kwenzeka entweni eyomile ngesikhathi senqubo yokungeniswa kokushisa. Ukungeniswa akuthathi ukudluliswa kokushisa kusuka kusifudumezi kuya kokuqukethwe. Ngenkathi ukusebenzisa ezinye izindlela zokomisa kudinga ukufudumeza umoya, bese udlulisa ukushisa kusuka emoyeni oshisayo kuya kokuqukethwe. Esigabeni ngasinye - ukushisa komoya, ukuthuthwa kwaso, kanye nokudluliswa kokushisa kwimikhiqizo - ukulahleka kokushisa akunakugwenywa.

Kulezi zinsuku amabhizinisi eKazakhstan empeleni awasebenzisi ama-heater wokungeniswa njengoba ebiza kakhulu. Amamodeli wamalambu amadala we imishini yokushisa engenayo ziphelelwe yisikhathi futhi azenziwanga.

Ukusanhlamvu okusanhlamvu ngokushisa kwe-induction. Omiswe kusendlalelo esiwayo

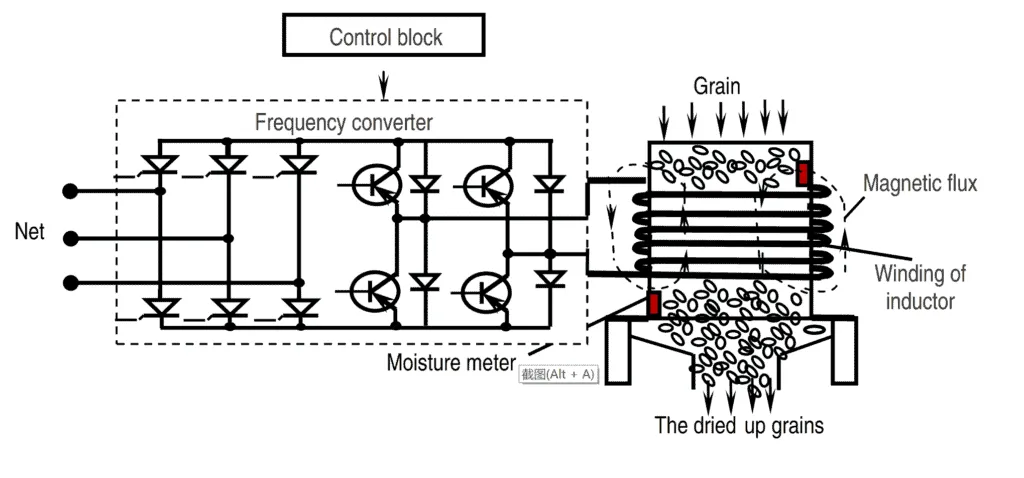

Siphakamisa indlela yokushisa yokungeniswa kokumiswa okusanhlamvu (Umdwebo 1) lapho okusetshenziswayo okusanhlamvu, kuqhutshwa ngamandla adonsela phansi, kushaft yokomisa. Phezulu kwenhlamvu eyomile kulayishwa abathuthi bamabhakede noma ezinye izinto zokuhamba; khona-ke okusanhlamvu kungena embhoshongweni wokoma. Kwikhamera yombhoshongo wokomisa i-inductor, exhunywe kwisiguquli semvamisa, idala inkambu ye-electromagnetic (flux) yemvamisa ephezulu.

Omiswe ungqimba oluwayo. Isendlalelo esiwayo sikhombisa ukusakazwa okusanhlamvu okukhipha amandla okukhulu okususwe, okususwe ngokwengxenye ngokugeleza okuphezulu kwegesi (ukubamba amabhuleki ashushumbisayo). Ukuhlungwa kwangempela okusanhlamvu kuyanda ngokuhamba. Omiswe kusendlalelo esimisiwe. Isimo sokumiswa kokusanhlamvu siyatholakala ekusakazeni kukaphethiloli lapho kukhuphuka isivinini sokuphakelwa kukagesi. Enkambeni yonke indawo yokusanhlamvu ibandakanyeka ekushisaneni nasekushiseni ngomswakama negesi. Isikhathi sokusanhlamvu okushubhu epneumo tube asidluli imizuzwana embalwa; Ukushisa kwe-agent yokumisa kwenza i-350-400 ° C. Kodwa-ke, ukunciphisa umswakama kufinyelela kumaphesenti wengxenyana. Ngakho-ke, amathuluzi anezingqimba ezinesisindo zokusetshenziswa awasetshenziswa njengesomisi esihlukile, kepha njengengxenye yokomisa okuhlanganisiwe okunamagumbi amaningi.

Isiphetho

Namuhla amafemu ezolimo namakheshi ahlinzekwa ikakhulukazi ngama-dry shaft shaft aqondile. Lezi zomisi ziphakamisa ukungalingani okukhulu ekushiseni nasekomeni okusanhlamvu, nakho okubangela izindleko ezinkulu zokomisa okushisa. Isizathu esiyinhloko lapha ukungapheleli ekunikezeni i-ejenti yokomisa nomoya osemkhathini kuzendlalelo zokusanhlamvu ezomisa amanzi.

Isimo esibalulekile somsebenzi wekhwalithi wokomisa okusanhlamvu ukupholisa okusanhlamvu okusanisiwe. Ngokuya ngohlelo amadivayisi wokupholisa ama-dryer okusanhlamvu aklanyelwe ukuthi izinga lokushisa okusanhlamvu kokukhiphayo lingadluli izinga lokushisa lomoya ngaphezulu kuka-10 ° C. Kodwa-ke, ngokwenza lokhu leli nani lifinyelela ngaphezu kuka-12 ° C lapho izinga lokushisa lomoya lingaphezu kuka-15 ° C. Futhi izomisi zesimanje zokusanhlamvu zinikela ngokungalingani okukhulu ekupholiseni izingqimba ngazinye zokusanhlamvu. Kumongo okuxoxwe ngawo ukusebenzisa ukomiswa kokushisa kwe-induction kungaba yindlela efanelekile ngokwengeziwe mayelana nokukhiqiza, ikhwalithi nokusebenza kahle kwezindleko.

Okubhekwayo

IBaum, A., 1983. Ukomiswa okusanhlamvu [ngesiRashiya], eMoscow: Kolos

Ginzburg, A., 1973. Okubalulekile kwe-theory nobuchwepheshe ekomisweni kokudla [ngesiRussia], eMoscow: Imboni yokudla

UZhidko, V., 1982. Ukomisa okusanhlamvu nokomisa okusanhlamvu [ngesiRashiya], eMoscow: Kolos