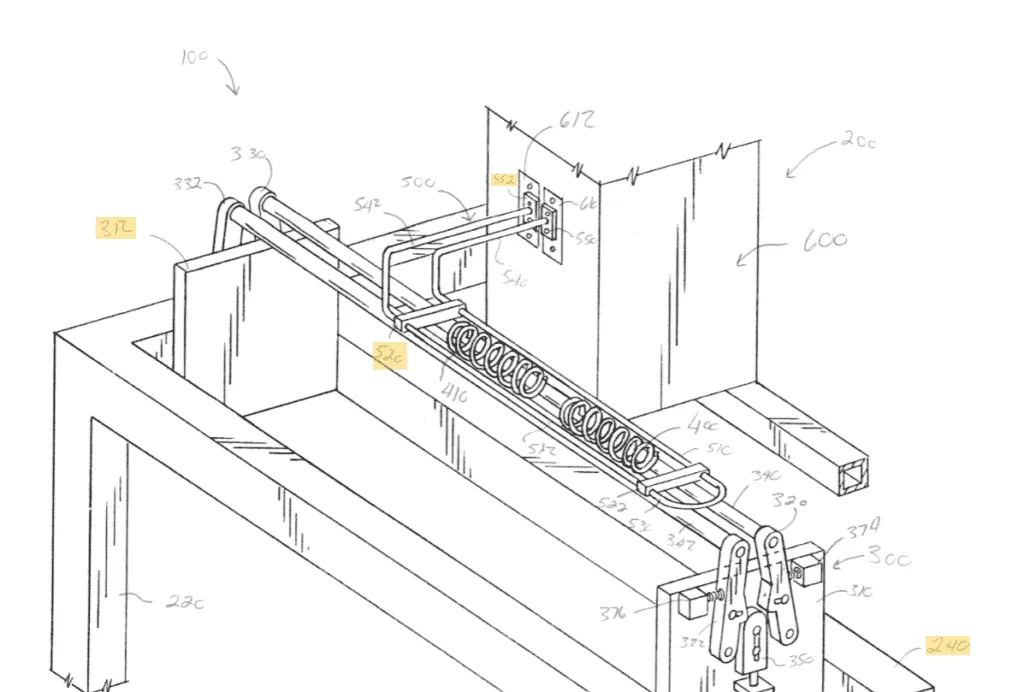

Isisetshenziswa se Ukuqeda ukuqina isiphethu esinesimo se-helical noma sezinyosi. Izinto zokusebenza zinohlelo lokusekelwa kokujikeleza kanye nohlelo lokushisa lokungeniswa. Uhlelo lokusekelwa kokujikeleza lwenzelwe ukuxhasa intwasahlobo ngenkathi intwasahlobo ishiswa ngohlelo lokushisa lokungeniswa. I- ukufakwa kokushisa uhlelo ine-coil induction system enesistimu yamakhoyili. Uhlelo lwekhoyili lunendawo enesikhala eyenzelwe ukwamukela intwasahlobo nokufudumeza intwasahlobo ngenkathi intwasahlobo isekelwa ohlelweni lokusekelwa kokujikeleza.

Imithombo yamakhoyili noma imithombo yamacembe yenziwa ngokuguquguquka okushisayo kwamaphrofayili wensimbi. Ngenxa yezici zensimbi yasentwasahlobo, kunezidingo ezithile zokushisa okushisa nesikhathi ngesikhathi senqubo yokushisa. Ngaphandle kokufudumeza ngaphambi kokungena kohlobo lwentwasahlobo noma ukufaka okokufaka emithonjeni yamaqabunga, kukhona nezinye izicelo zokwelashwa okushisayo okuhlukile, njengokufakwa kwentambo yentambo entanjeni, nokuqina kwensimbi kwangaphakathi. Ukuba nezimpawu zokushisa okusheshayo, ukuvala shaqa, ukulawula amandla okuphuma kwamandla, futhi kuyahlukahluka kumabanga amabanga, ama-HLQ Ukukhishwa kwamandla okushisa ilungele kakhulu ukushisa kokushiswa okushisayo kwensimbi yasentwasahlobo, ikakhulukazi embonini yezingxenye ezizenzakalelayo efaka amaqabunga emithombo noma izitshalo zokukhiqiza ezithwala intwasahlobo. Kwadalwa ochwepheshe at HLQ, yethu amadivayisi wokushisa wokungeniswa konke kuhlome kahle ngezinzuzo zokonga amandla, ukuqala / ukuma okusheshayo, isikhathi somjikelezo womsebenzi wamahora angama-24, iphoyinti eliphezulu lamandla, ukuzenzekelayo okuphezulu, ukusebenza kahle okuphezulu, ukugcinwa okulula, nempilo yokusebenzisa isikhathi eside. Ama-heater wethu wokungeniswa abonwe kabanzi ngamakhasimende embonini yokukhiqiza yensimbi yasentwasahlobo.

Imithombo yamakhoyili noma imithombo yamacembe yenziwa ngokuguquguquka okushisayo kwamaphrofayili wensimbi. Ngenxa yezici zensimbi yasentwasahlobo, kunezidingo ezithile zokushisa okushisa nesikhathi ngesikhathi senqubo yokushisa. Ngaphandle kokufudumeza ngaphambi kokungena kohlobo lwentwasahlobo noma ukufaka okokufaka emithonjeni yamaqabunga, kukhona nezinye izicelo zokwelashwa okushisayo okuhlukile, njengokufakwa kwentambo yentambo entanjeni, nokuqina kwensimbi kwangaphakathi. Ukuba nezimpawu zokushisa okusheshayo, ukuvala shaqa, ukulawula amandla okuphuma kwamandla, futhi kuyahlukahluka kumabanga amabanga, ama-HLQ Ukukhishwa kwamandla okushisa ilungele kakhulu ukushisa kokushiswa okushisayo kwensimbi yasentwasahlobo, ikakhulukazi embonini yezingxenye ezizenzakalelayo efaka amaqabunga emithombo noma izitshalo zokukhiqiza ezithwala intwasahlobo. Kwadalwa ochwepheshe at HLQ, yethu amadivayisi wokushisa wokungeniswa konke kuhlome kahle ngezinzuzo zokonga amandla, ukuqala / ukuma okusheshayo, isikhathi somjikelezo womsebenzi wamahora angama-24, iphoyinti eliphezulu lamandla, ukuzenzekelayo okuphezulu, ukusebenza kahle okuphezulu, ukugcinwa okulula, nempilo yokusebenzisa isikhathi eside. Ama-heater wethu wokungeniswa abonwe kabanzi ngamakhasimende embonini yokukhiqiza yensimbi yasentwasahlobo.

Inqubo yokuqinisa insimbi yensimbi inqubo ejwayelekile esetshenziselwa ukwenziwa kwentwasahlobo. Inqubo eyodwa ejwayelekile yokuqina iqukethe isithando somlilo sendabuko. Izinqubo ezinjalo zokuqina zihamba kancane. Iziphethu zingakhiwa ngezinsimbi ezahlukahlukene (isb., Insimbi engagqwali, i-carbon steel, i-alloy steel, njll.). Lapho insimbi yasentwasahlobo iqina kahle futhi imnene, kungatholwa imingcele ethile yensimbi efana nobulukhuni nesakhiwo esincane.

Lapho intwasahlobo iqina ngesithando somkhathi sendabuko, intwasahlobo iqala ibekwe kuhhavini ebekwe ezingeni lokushisa elithile isikhathi esithile. Ngemuva kwalokho, intwasahlobo iyasuswa icishwe emafutheni noma kolunye uketshezi olucimayo. Ngemuva kwale nqubo yokuqala yokuqina, ubulukhuni basentwasahlobo ngokuvamile buphakeme kunalokho obekufiswa. Ngakho-ke, intwasahlobo imvamisa iba ngaphansi kwenqubo yokushisa kuze kube intwasahlobo ithola izakhiwo ezifunwayo zomzimba. Lapho intwasahlobo icutshungulwa kahle, okunye okwakhiwe ngekristalu kwensimbi kuyashintshwa kube yi-martensite enomoya omningi we-carbides oncibilikisiwe ukuhlinzeka ngesakhiwo somgogodla oyifunayo wentwasahlobo nobulukhuni obufunwa entwasahlobo.

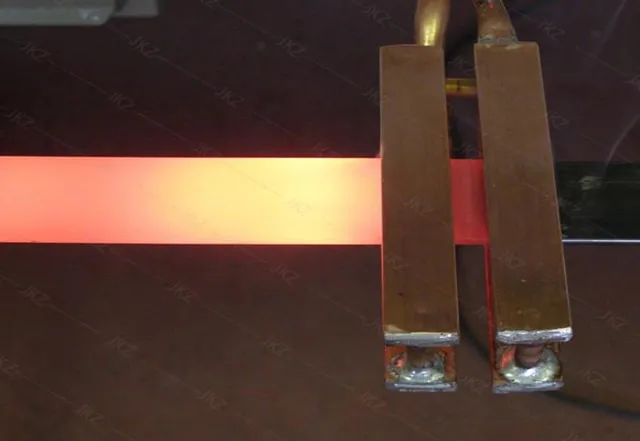

Enye inqubo esetshenziselwa ukuqina kweziphethu yile

Ukushisa ukufakelwa. Inqubo yokushisa yokungeniswa yenzeka ngokuheha insimu ye-electromagnetic entweni eqhubayo yasentwasahlobo. Imisinga ye-Eddy yenziwa ngaphakathi kwento eqhubayo ukumelana kwayo okuholela ekushiseni kweJoule. Ukushisa kwe-induction kungasetshenziselwa ukufudumeza insimbi iye endaweni yayo yokuncibilika uma kunesidingo esingaphezu kokwanele ukwenza umkhiqizo ube lula.

Inqubo yokushisa ye-induction ingahlinzeka ngesikhathi sokushisa esisheshayo kunokushisa ngamahhavini asemkhathini wendabuko, futhi inqubo yokushisa yokungeniswa ingenza lula ukuphathwa kwempahla yemithombo, futhi ingavumela ukuzenzakalela kokuphathwa kwempahla entwasahlobo kunqubo yokuqina. Yize ukufudumeza kokungeniswa kunezinzuzo ezimbalwa ngaphezulu kwamahhavini asemkhathini wendabuko, ukufudumeza induction kweziphethu kunezinkinga ngokushisa ngokulinganayo intwasahlobo phakathi nobude bentwasahlobo, ukushisa kakhulu ukuphela kwentwasahlobo, nokugcinwa kwe

ukufakwa kwe-coil yokushisa ukusebenza kahle.

Imithombo yamakhoyili noma imithombo yamacembe yenziwa ngokuguquguquka okushisayo kwamaphrofayili wensimbi. Ngenxa yezici zensimbi yasentwasahlobo, kunezidingo ezithile zokushisa okushisa nesikhathi ngesikhathi senqubo yokushisa. Ngaphandle kokufudumeza ngaphambi kokungena kohlobo lwentwasahlobo noma ukufaka okokufaka emithonjeni yamaqabunga, kukhona nezinye izicelo zokwelashwa okushisayo okuhlukile, njengokufakwa kwentambo yentambo entanjeni, nokuqina kwensimbi kwangaphakathi. Ukuba nezimpawu zokushisa okusheshayo, ukuvala shaqa, ukulawula amandla okuphuma kwamandla, futhi kuyahlukahluka kumabanga amabanga, ama-HLQ Ukukhishwa kwamandla okushisa ilungele kakhulu ukushisa kokushiswa okushisayo kwensimbi yasentwasahlobo, ikakhulukazi embonini yezingxenye ezizenzakalelayo efaka amaqabunga emithombo noma izitshalo zokukhiqiza ezithwala intwasahlobo. Kwadalwa ochwepheshe at HLQ, yethu amadivayisi wokushisa wokungeniswa konke kuhlome kahle ngezinzuzo zokonga amandla, ukuqala / ukuma okusheshayo, isikhathi somjikelezo womsebenzi wamahora angama-24, iphoyinti eliphezulu lamandla, ukuzenzekelayo okuphezulu, ukusebenza kahle okuphezulu, ukugcinwa okulula, nempilo yokusebenzisa isikhathi eside. Ama-heater wethu wokungeniswa abonwe kabanzi ngamakhasimende embonini yokukhiqiza yensimbi yasentwasahlobo.

Imithombo yamakhoyili noma imithombo yamacembe yenziwa ngokuguquguquka okushisayo kwamaphrofayili wensimbi. Ngenxa yezici zensimbi yasentwasahlobo, kunezidingo ezithile zokushisa okushisa nesikhathi ngesikhathi senqubo yokushisa. Ngaphandle kokufudumeza ngaphambi kokungena kohlobo lwentwasahlobo noma ukufaka okokufaka emithonjeni yamaqabunga, kukhona nezinye izicelo zokwelashwa okushisayo okuhlukile, njengokufakwa kwentambo yentambo entanjeni, nokuqina kwensimbi kwangaphakathi. Ukuba nezimpawu zokushisa okusheshayo, ukuvala shaqa, ukulawula amandla okuphuma kwamandla, futhi kuyahlukahluka kumabanga amabanga, ama-HLQ Ukukhishwa kwamandla okushisa ilungele kakhulu ukushisa kokushiswa okushisayo kwensimbi yasentwasahlobo, ikakhulukazi embonini yezingxenye ezizenzakalelayo efaka amaqabunga emithombo noma izitshalo zokukhiqiza ezithwala intwasahlobo. Kwadalwa ochwepheshe at HLQ, yethu amadivayisi wokushisa wokungeniswa konke kuhlome kahle ngezinzuzo zokonga amandla, ukuqala / ukuma okusheshayo, isikhathi somjikelezo womsebenzi wamahora angama-24, iphoyinti eliphezulu lamandla, ukuzenzekelayo okuphezulu, ukusebenza kahle okuphezulu, ukugcinwa okulula, nempilo yokusebenzisa isikhathi eside. Ama-heater wethu wokungeniswa abonwe kabanzi ngamakhasimende embonini yokukhiqiza yensimbi yasentwasahlobo.