Amakhoyili E-Induction Brazing

Incazelo

Amakhoyili E-Induction Brazing

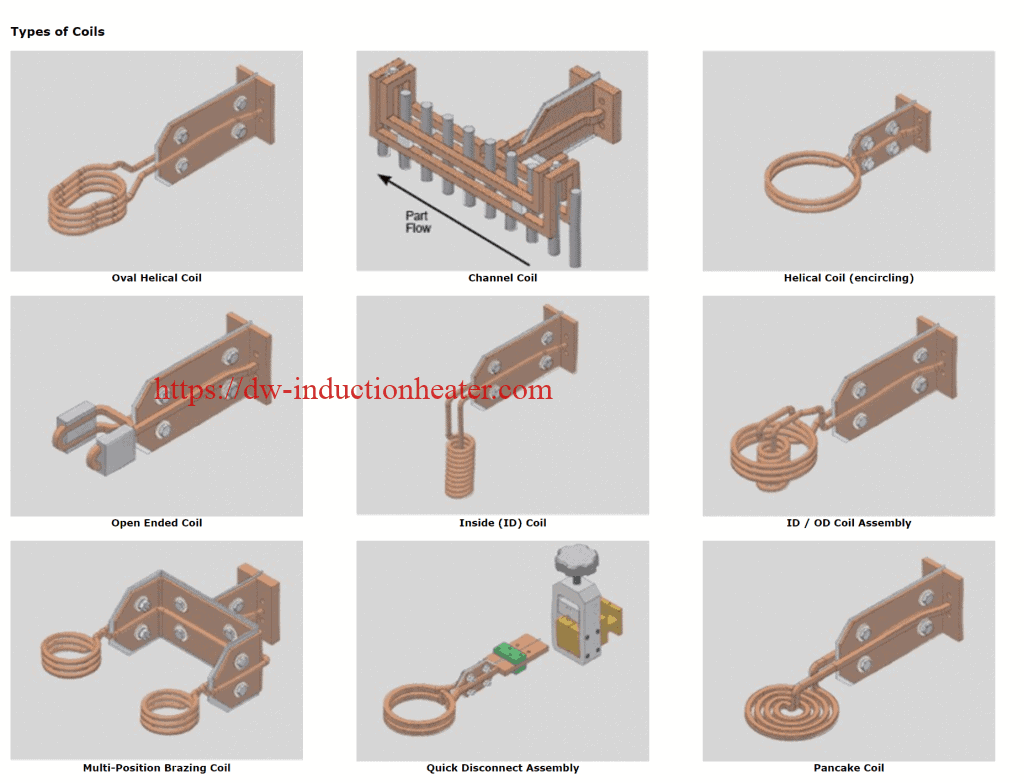

Kungakhathaliseki ukuthi ubujamo, ubukhulu, noma isitayela coil induction udinga, singakusiza! Nawa ambalwa nje wamakhulu wemiklamo yamakhoyili esisebenze nawo. Ama-pancake coil, ama-helical coils, ama-concentrator coil… i-tubing eyisikwele, eyindilinga neyikwele ... Noma yini oyidingayo, sithumele imidwebo yakho nezincazelo zesilinganiso esisheshayo. Uma umusha ekufudumaleni kokungeniswa, sithumele izingxenye zakho ukuze kuhlolwe mahhala.Iyikhoyili yokungeniswa enconyelwe ithuluzi elifanele elijwayele ukuphumelela noma ukwehluleka kohlelo lonke.

Ukwakhiwa kwe-Coil Design Coil

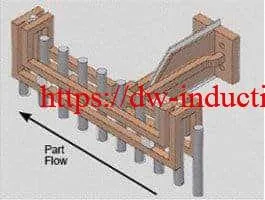

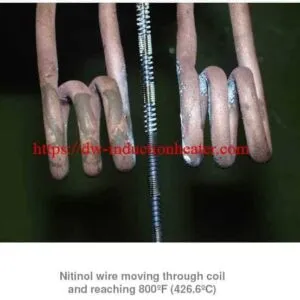

Bhila kusukela conductive kakhulu zethusi tubing noma plate, ukukhipha izinsimbi zokushisa izinsimbi kuthonywa isicelo, ukukhethwa imvamisa, amandla ukuminyana futhi ukushisa isikhathi. Injongo ikhoyili lokungeniswa ukudala kazibuthe ecucuza iphethini ukukhiqiza indlela samanje ucezu umsebenzi ngokukhetha ukufudumeza endaweni inhlangano ukuba brazed.

The Ikhoyili ye-Induction kumele kube kahle emhlanganweni ukuvumela ukushisa okudingekayo kufezeke. Umkhawulo womoya noma isikhala sokuhlanganisa phakathi komsebenzi womsebenzi ngaphakathi nangaphakathi kwekhoyili kufanele kuncishiswe ngenxa yezizathu zokusebenza kahle. Izikhala ezijwayelekile zokuklama ye-0.125 intshi (3.175 mm) kuya ku-0.250 intshi (6.350 mm) zinengqondo ngokukhanda nge-coil ye-helical.

Izigaba ezingenakubalwa zingahle zidinge izimvume ezengeziwe ezidinga amandla engeziwe ukuze kunqobe lokhu okusebenza kahle kokuhlanganiswa okungalungile. Lezi zimo zihlanganisa izimo lapho kubonakala khona ikhoyili eyindilinga enomkhawulo omkhulu we-air noma i-coil engeyona ehambelayo ukuze ufinyelele endaweni yesibhakabhaka.

Indawo yokushisa inquma ubude bekhoyili yokufakelwa. An coil induction ukuthi mfushane kakhulu kuzodinga isikhathi esiphezulu sokushisa ukuvumela ukushisa, ngokuqhuba, ukumboza indawo. An ukufakwa kwe-coil yokushisa lokho kukhulu kakhulu kuzotshisa insimbi eningi kunesidingo, ngakho-ke ngeke kusebenze kancane. Umshini wokushisa we-HLQ Co unemiklamo eminingi ekhethekile ye-inductors yokushisa okusetshenziselwa indawo, nama-coil akhanyisa kahle ngaphandle kokuzungeze ucezu lomsebenzi.

Eyenziwe nge-tubing noma ipulasitiki ephethe kahle kakhulu, ukuklanywa kwe-coil ye-induction kuthonywa uhlelo lokusebenza, ukukhethwa kwamaningi, amandla omzimba kanye nesikhathi sokushisa. Inhloso ye-coil yokufakelwa ukudala iphethini le-magnetic flux ukudala indlela yamanje emkhatsini womsebenzi ukushisa ngokufudumele indawo yomhlangano ozokhishwa.

Ikhoyili lokungeniswa kumele kahle isebangeni inhlangano okuvumela Ukushisa edingekayo ukuze kufezeke. Igebe emoyeni noma isikhala coupling phakathi ucezu umsebenzi ingaphakathi Ikhoyili kumele zincishiswe ngenxa kahle. Ejwayelekile design izikhala of 0.125 intshi (3.175 mm) ukuze 0.250 intshi (6.350 mm) ziyafinyeleleka ngoba brazing nge ikhoyili Helical.

Izigaba ezingenakubalwa zingahle zidinge izimvume ezengeziwe ezidinga amandla engeziwe ukuze kunqobe lokhu okusebenza kahle kokuhlanganiswa okungalungile. Lezi zimo zihlanganisa izimo lapho kubonakala khona ikhoyili eyindilinga enomkhawulo omkhulu we-air noma i-coil engeyona ehambelayo ukuze ufinyelele endaweni yesibhakabhaka.

Le ndawo sishiswa inquma ubude ikhoyili lokungeniswa. Kuvele ikhoyili lokungeniswa ukuthi kufushane kakhulu azodinga isikhathi eside amalahle ukuvumela ukushisa, by conduction, ukumboza indawo. Kuvele ikhoyili lokungeniswa ukuthi ubanzi kakhulu ngeke ukufudumeza metal ngaphezu kudingekile, futhi ngenxa yalokho kube ngaphansi kahle. HLQ Ukushisa ukufakelwa Co sinephethini eziningi olukhethekile lokungeniswa ohlobo Ukushisa ezenziwe zendawo, nocingo ukuthi nokushisa kahle ngaphandle ezizungezile ucezu umsebenzi.

Ukwakhiwa kwe-Coil Designing Coil Design ne-Basic Design