Inhloso

Ukubethelwa Okukhulu Kwezikhathi Ezijwayelekile steel carbide cap kushaft. Njengamanje iKhasimende lisebenzisa inqubo yesibani, kepha lingathanda ukushintshela ekubambeni ngomshini ukuze kuncishiswe imfucumfucu iphinde isebenze futhi ithuthukise ikhwalithi ye-braze.

Isisetshenziswa

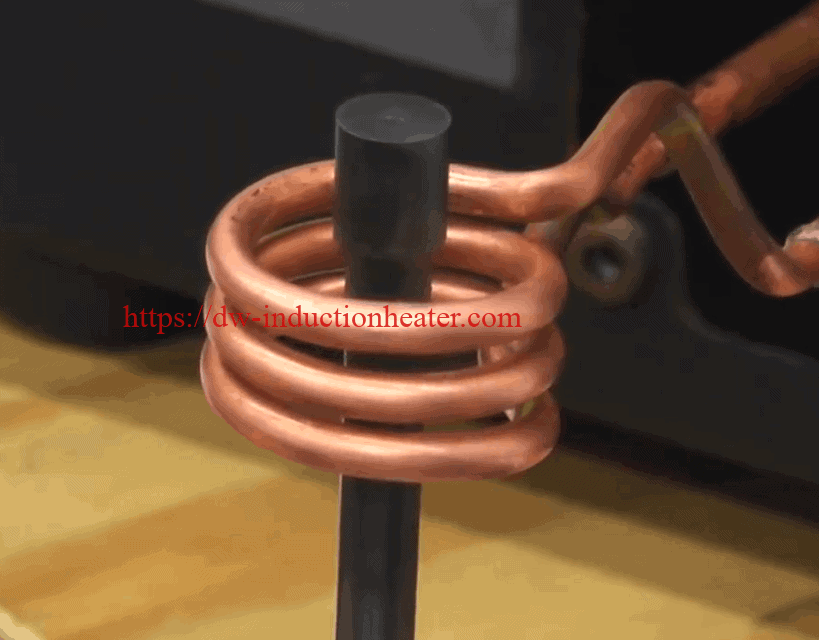

I-DW-UHF-6kw-III lokungeniswa aphathwayo brazing heater

Materials

• Insimbi yeCarbon

• Izibalo ze-magnetic carbide

• I-alloy - unamathisela i-EZ Flo 3

• Isivivinyo 1: Ububanzi beShaft: 0.5 ”(12.7 mm)

• Isivivinyo 2: Ububanzi beShaft: 0.375 ”(9.525mm)

• Isivivinyo 3: Ububanzi beShaft: 0.312 ”(7.925mm)

Inqubo:

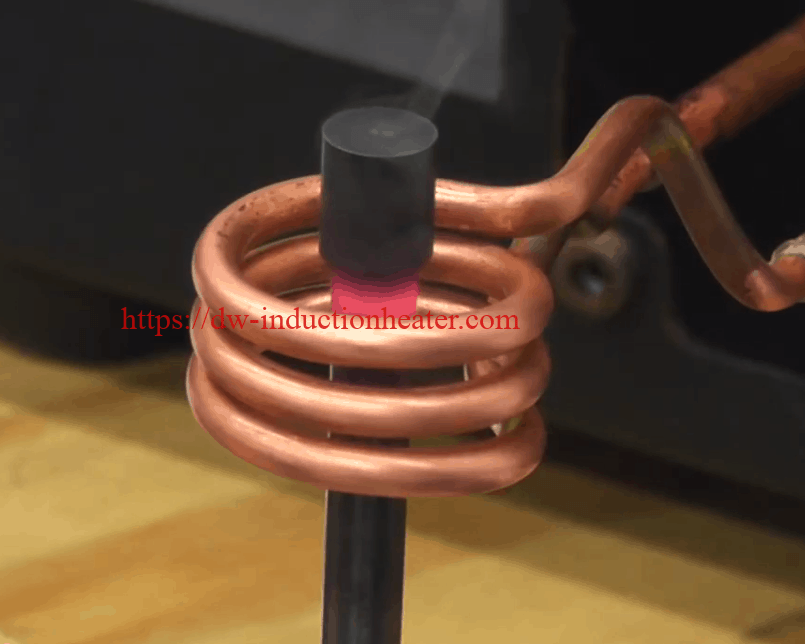

- I-paste alloy yayisetshenziselwa ukwakheka kwesigaxa ngaphezulu kwetshe ngalinye lensimbi.

- I-cap ibekwe phezulu futhi ijikelezwe ukusabalalisa i-paste alloy.

- Umhlangano ngamunye wawubekwe koyili futhi ufudumale.

- Ukuhlolwa kokushisa okuqala kwenziwa kwenziwa kusetshenziswa upende we-tempilaq ukulinganisa umjikelezo wokushisa ukufika kuma-1450 degrees F.

Imiphumela / Izinzuzo:

- Ukulawulwa okuqondile kwesikhathi kanye namazinga okushisa okuholela kukhwalithi ethuthukisiwe nomphumela ohambelanayo

- Amandla afunwayo ngemijikelezo yokushisa esheshayo

- Inqubo ephindaphindwayo, ayinciki kumsebenzisi

- Safe Ukushisa ukufakelwa ngaphandle kwamalangabi avulekile

- Ukushisa kwamandla okusebenzayo