Vacuum Atmosphere Heat Treatment Furnace enomoya oshisayo

Incazelo

The I-Vacuum Atmosphere Heat Treatment Furnace iye yavela njengobuchwepheshe obubalulekile kusayensi yezinto zesimanje, enikeza ukulawula okungenakuqhathaniswa ezimweni zemvelo phakathi nenqubo yokwelapha ukushisa. Lesi sihloko sidingida ubunkimbinkimbi balesi simiso, sihlola ukwakheka, ukusebenza, izinzuzo, kanye nokusetshenziswa kwalo embonini.

The I-Vacuum Atmosphere Heat Treatment Furnace imele ukugxumela phambili okubalulekile, ihlinzeka ngendawo engenakho ukungcola evumela ukulawulwa okunembile kwezinga lokushisa kanye nezimo zomoya. Lobu buchwepheshe buye baba wusizo ezimbonini ezahlukene ezidinga izinto zokusebenza ezisebenza kahle, okuhlanganisa i-aerospace, imboni yezimoto, kanye neyokwenza amathuluzi.

| izinto | Ipharamitha |

| Temperature | I-1000 ℃ |

| imodeli | I-GWL-1000VSF |

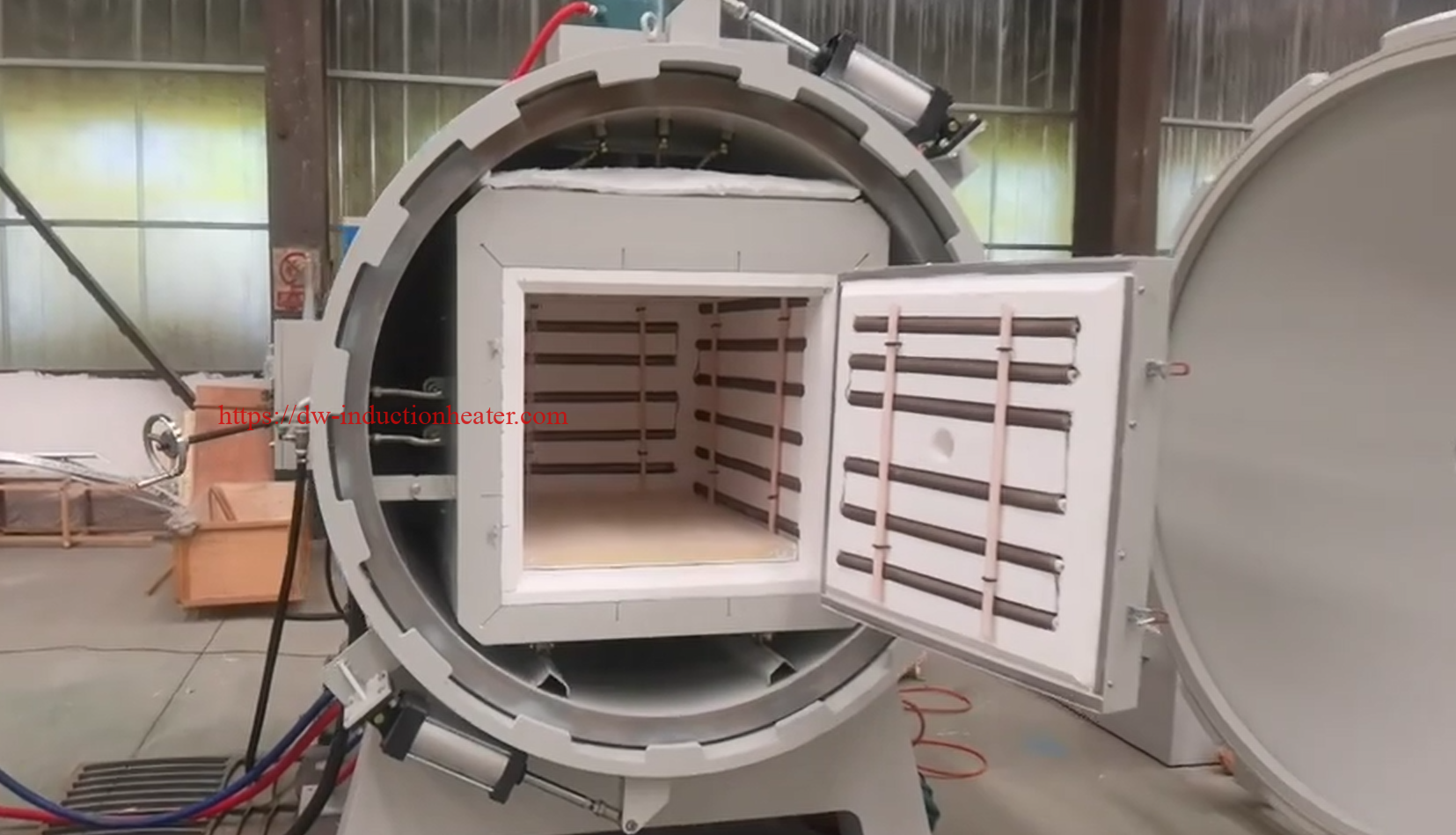

| Usayizi wesithando somlilo (mm) | Ukujula×ububanzi×ubude: 600×600×900 |

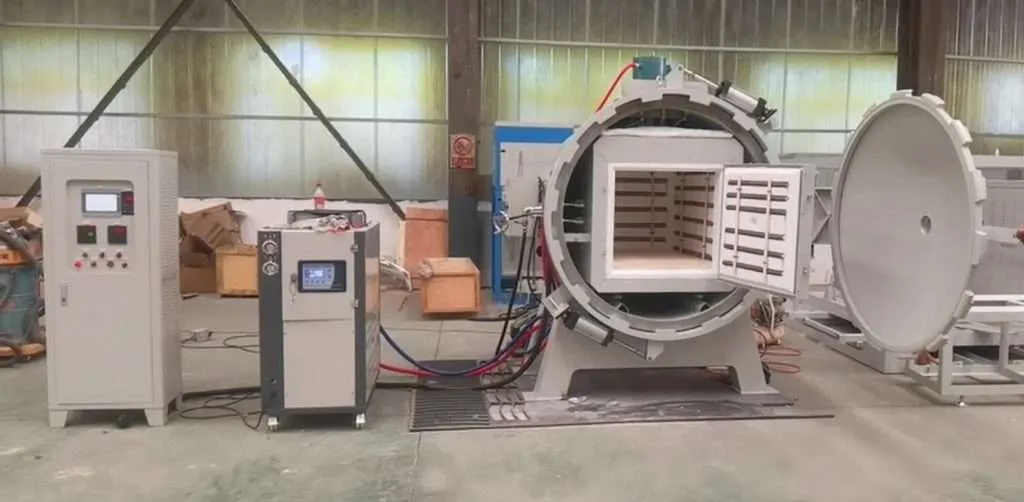

| amandla | 45KW |

| I-VoltageAC | 380V |

| amandla Maximum | Amandla okuklama angama-75KW, futhi amandla angempela asetshenzisiwe angaphakathi kwama-85%. Amandla angashintshwa ngokuzenzakalela ngokuya ngezinqubo ezihlukene zokushisa. |

| Ukulawula ukulawula izinga lokushisa | ±1 ℃ (Ukulawulwa kwesekethe okudidiyelwe, akukho kudubula okweqile) |

| Ububanzi bokulawula bu | 50 kuye ku-1000 degrees |

| Izinga lokushisa elifanayo esithandweni somlilo | ±5 ℃ |

| Isici sokulinganisa izinga lokushisa nobubanzi bokulinganisa izinga lokushisa | Uhlobo lwe-Thermocouple K, izinga lokushisa lokulinganisa ibanga 0-1320 degrees |

| Izinga lokushisa | Izinga lokushisa lingalungiswa ngokukhululekile, futhi ububanzi bokulungisa buwukuthi: izinga lokushisa elisheshayo lingama-degree angu-15 ngomzuzu (amadigri angu-15/min), futhi izinga lokushisa eliphansi kakhulu yi-1 degree ngehora (1 degree/h). |

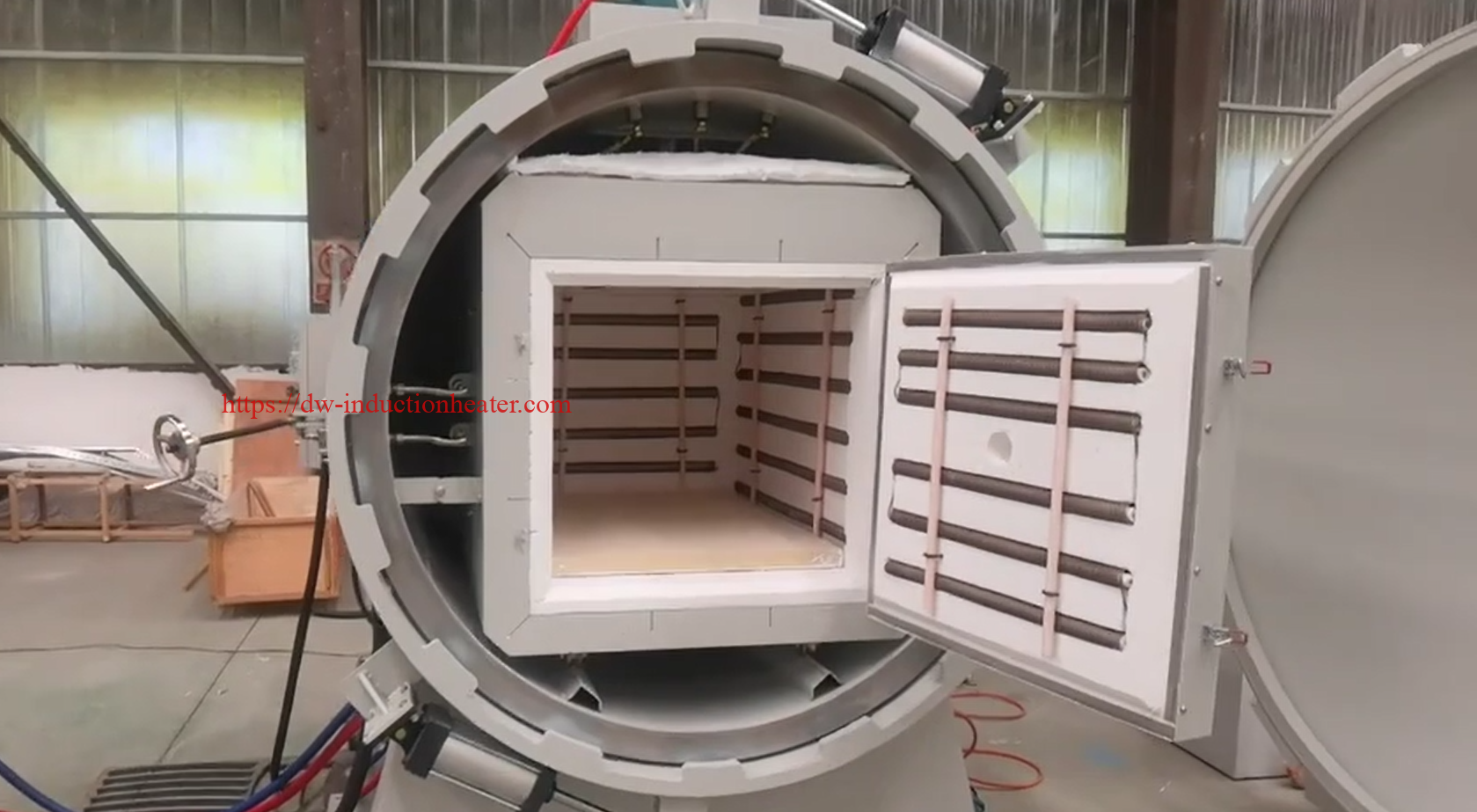

| Isici sokushisa | I-Beijing Shougang HRE i-alloy resistant wire (equkethe i-molybdenum ) isetshenziswa futhi ilinyazwe ibe yisimo sentwasahlobo esi-spiral. |

| Indawo yokufaka izinto zokushisisa | Isatshalaliswa ngokulinganayo ngaphakathi kwesithando somlilo + phansi, futhi isebenzisa ukufudumeza okunezinhlangothi ezinhlanu. Umzimba wokushisa ukhiqiza ukushisa ngokulinganayo, futhi inkambu yokushisa esithandweni iyafana futhi umphumela muhle. |

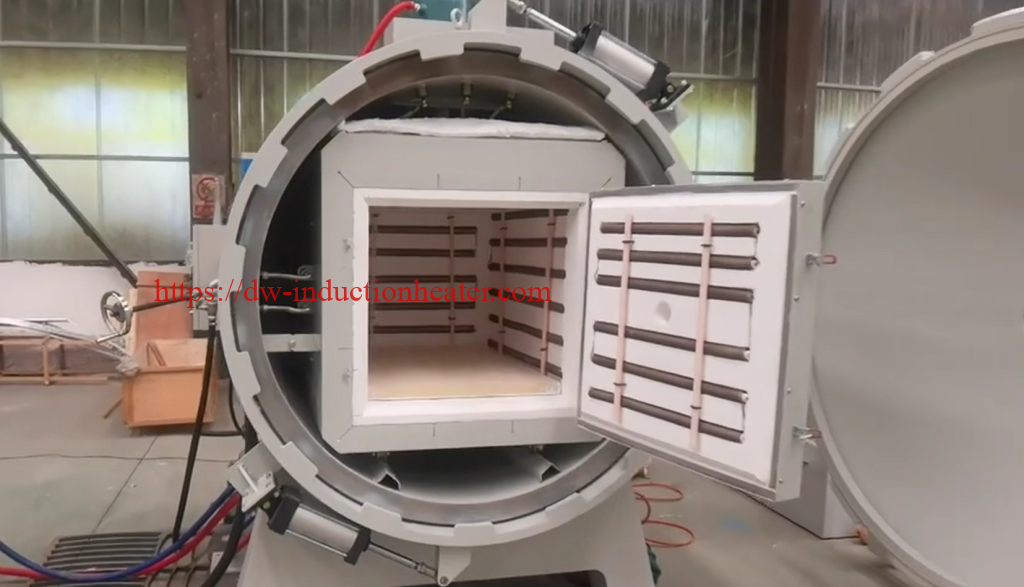

| Umzimba wesithando somlilo | Umzimba wesithando somlilo ucutshungulwa ngamathuluzi omshini we-CNC, futhi wenziwa ngokupholisha, ukugaywa, ukucotshwa, uphosphating, ukufafaza impushana yepulasitiki, ukubhaka okunokushisa okuphezulu, njll. Inemibala emibili ehambisanayo, inoveli nokubukeka okuhle, futhi ine-anti- i-oxidation, ukumelana ne-asidi ne-alkali, ukumelana nokugqwala, nokumelana nokugqwala. Izinga lokushisa eliphezulu, kulula ukuhlanza kanye nezinye izinzuzo |

| Ukwakhiwa kwesithando somlilo | Umzimba wesithando somlilo kagesi wamukela uhlaka lwesithando somlilo olusezingeni eliphansi lomhlaba olusezingeni eliphindwe kabili. I-partition esebenzayo yomhlahlandlela wokupholisa umoya izungeza umoya obandayo kulo lonke igobolondo lesithando somlilo, futhi ekugcineni ipholise amashidi e-conductive wesici sokushisa bese ikhipha umzimba wesithando somlilo, igwema i-oxidation ephezulu yokushisa yamashidi e-conductive wesici sokushisa. ; Qinisekisa indawo yokusebenza enhle |

| Iwindi lokuqaphelisa | Umnyango wesithando somlilo ufakwe iwindi lokubuka |

| Indlela yokuvula umnyango wesithando somlilo | Indlela yokuvula umnyango wesithando somlilo ukuvuleka komnyango oseceleni. |

| Umnyango wesithando ukhiyiwe | Sebenzisa umnyango womlilo wokukhiya umoya |

| Ukushisa kwegobolondo lesithando somlilo | ukusetshenziswa isikhathi eside , futhi izinga lokushisa langaphandle legobolondo lingaphansi kwama-45 degrees. |

| Ukunyakazisa umoya oshisayo | Umsebenzi wokunyakazisa umoya oshisayo: Kuneqabunga lomoya phezulu kwesithando somlilo. Ngokujikeleza kweqabunga lomoya , izinga lokushisa lesikhala ngaphakathi kwesithando somlilo lisakazwa ngokulinganayo, ukuze kufezwe injongo yokushisa okufanayo esithandweni somlilo. |

| Hlanganisa i-blade | I-310S insimbi engagqwali, izinga lokushisa elisebenzayo elingaphansi kwama-degree angu-1050 |

| Injini eshukumisayo nesivinini | I-motor yokuxuba ipholile ngamanzi, futhi isivinini silungiswa ngokungenamkhawulo ngokusebenzisa isiguquli semvamisa. Amandla 3KW |

| Isistimu yokupholisa ephoqelelwe | Isithando somlilo sifakwe ikhoyili yokupholisa yensimbi engenasici, engagcwaliswa ngamanzi ajikelezayo endaweni ebandayo ukuze kusheshiswe ukuchithwa kokushisa esithandweni, kwandise isivinini sokupholisa, futhi kuthuthukiswe ukusebenza kahle kwemishini. Uhlelo lwamanzi abandayo ajikelezayo lwamukela uhlelo lokujikeleza oluvaliwe, olwakhiwe isipholile samanzi esivaliwe, ama-valve okulawula kanye namapayipi ensimbi engagqwali, okungathuthukisa ngempumelelo ukusetshenziswa kwemishini. Isivinini sokupholisa singaqinisekiswa ukuthi singu-≮ 35 ℃ / h, esingahlangabezana nesidingo sokuvula umnyango wesithando somlilo lapho izinga lokushisa lomlilo lehla liye ku-70 ℃ phakathi namahora angu-10. |

| Isiqandisisi | 3P |

| Umshini futha | Yamukela iphampu ye-rotary ejikelezayo enezigaba ezimbili engu-70L/s |

| I-degree yokuvota | -0.1Mpa. |

| Ukumelana nengcindezi | Ipuleti lensimbi lesithando somlilo sikagesi lingu-6-20mm obukhulu, lishiselwe emaceleni amabili, futhi lingakwazi ukumelana nokucindezela okuhle okungu-0.1Mpa. |

| I-valve yomoya | Amavalvu ensimbi engagqwali angenisiwe |

| Ukutholwa kwengcindezi | Ingcindezi ephozithivu kanye negeji yokulinganisa ingcindezi yesikhombi esiphindwe kabili

Ingcindezi enhle negeji ye-digital pressure inkomba engalungile |

| I-Barometer | Amamitha amabili okugeleza okuntantayo |

| ukuphuza umoya | 2 |

| qeda umoya | 1 |

| Izimpawu | Isigxivizo senziwe ngendandatho yerabha ye-silicone ekwazi ukumelana nokushisa okuphezulu (izinga lokushisa likwazi ukumelana nama-260 degrees-350 degrees) |

| ukuvikelwa kwengcindezi | Ukuze uvimbele imbobo yokukhipha isithando somlilo ukuthi ivalwe, imbobo yokukhipha umoya ivinjiwe, futhi ingcindezi yesithando somlilo iphezulu kakhulu, le sistimu iklanywe ngokukhethekile. Umgomo uthi: igeji yengcindezi yokuxhumana kagesi noma inzwa yokucindezela ithola isignali, ishayela imojula yokulawula ukuvala ivalve yokungena yomoya kagesi, bese iqala i-electromagnetic exhaust valve. Ivalvu yomoya kanye ne-alamu kukhulula ukucindezela okuvela ku-exhaust port, futhi i-alamu yomsindo ne-alamu ekhanyayo ikhala i-alamu. Ukuvikela ukusebenza okuvamile kwesithando somlilo kagesi |

| isimo esifinyelelekayo | I-hydrogen, i-nitrogen, i-argon, i-carbon monoxide, i-oxygen, njll. |

| Izinto zokukhomba | Ilayini yesithando somlilo yenziwe nge-vacuum-formed high-purity high-purity alumina poly-light materials. Amapuleti e-alumina ayindilinga angenalutho angasindi asetshenziselwa ukuphatha izinto ezibonakalayo okulula ukuzithinta kanye nezindawo ezithwala imithwalo (umlomo wesithando somlilo kanye naphansi kwesithando somlilo). Inezinga lokushisa eliphezulu lokusebenza, isitoreji esiphansi sokushisa, futhi imelana nokushisa okusheshayo nokupholisa ngokushesha. , akukho mifantu, akukho slag, ukusebenza kahle kokufakwa kwe-thermal (umphumela wokonga amandla ungaphezu kuka-80% wesithando somlilo esidala sikagesi) |

| Izinto zokufakelwa | Yamukela izingqimba ezintathu zokugquma, okuyizi: ibhodi le-aluminium silicate fiber, i-alumina fiber board, ne-alumina (polycrystalline) fiber board. Umphumela wokonga amandla ungaphezu kuka-80% walowo wesithando somlilo esidala sikagesi. |

| Vikela | Kusetshenziswa iyunithi yokulawula ehlanganisiwe ye-modular, ukunemba kokulawula kunembile, futhi isilawuli se-dual-loop kanye nokuvikelwa kwe-dual-loop kwakhiwa, nge-overshoot, i-overshoot, i-undershoot, ukuhlanganisa ingxenye, ukulahlekelwa kwesigaba, ukugcwala ngokweqile, i-overcurrent, izinga lokushisa ngokweqile, kanye nempendulo yamanje , isiqalo kanye nokunye ukuvikela |

| isilawuli | Ukwamukela ubuchwepheshe obuvaliwe be-thyristor module trigger control, indlela yokulawula i-trigger ye-phase-shift, i-voltage ephumayo, yamanje noma amandla ashintshwa ngokuqhubekayo, anezici ze-voltage engaguquki, amandla amanje noma angashintshi; iluphu yamanje iyiluphu yangaphakathi kanti iluphu ye-voltage iyiluphu yangaphandle. Uma umthwalo wengezwa ngokuzumayo noma umthamo wamanje udlula inani lamanje lomkhawulo, umthamo wamanje ophumayo we-voltage regulator ulinganiselwe ebangeni lamanje elilinganiselwe ukuze kuqinisekiswe ukusebenza okuvamile kokuphumayo kanye nesilawuli se-voltage; ngesikhathi esifanayo, i-voltage loop iphinde ibambe iqhaza ekulungiseni, ukuze ukukhishwa kwamanje kwesilawuli se-voltage Kukhawulelwe ebangeni lamanje elilinganiselwe futhi igcina ukukhishwa okuqhubekayo kwamanje kanye ne-voltage ene-margin eyanele yokulungisa; ngaleyo ndlela kuvikela isici sokushisa emthelela wamanje kanye ne-voltage ngokweqile, futhi kuzuzwe umphumela wokulawula ophephile nothembekile kanye nokunemba kokulawula. |

| Khombisa amapharamitha | Izinga lokushisa, inombolo yesigaba sezinga lokushisa, isikhathi sesikhathi, isikhathi esisele, iphesenti lamandla okukhiphayo, i-voltage, yamanje, njll. |

| inkinobho | Izinkinobho ezingenisiwe zinempilo yesevisi izikhathi ezingaphezu kuka-100,000 futhi zifakwe izinkomba ze-LED. |

| Ukulungiselelwa kwejika lokushisa | Kusetshenziswa irekhoda engenaphepha yesikrini esingu-7 intshi |

| ukulawula kwezinga lokushisa | Thola isilawuli sokushisa esihlakaniphile |

| Okokufaka kwamajika amaningi | Umsebenzi wokulawula uhlelo lwezingxenye ezingu-30, ungafaka izilungiselelo: ijika elilodwa linamasegimenti angu-30, amajika amabili anezigaba ezingu-14/umcu, amajika amathathu angamasegimenti/ingxenye engu-9, amajika amahlanu angamasegmenti/umcu; amajika amaningi angafakwa ngesikhathi esisodwa, futhi angasetshenziswa lapho azodluliswa khona. |

| Isizinda Sokuxhumana | RS485 RS232 USB |

| I-alamu nokuvikelwa | Faka i-alamu ezwakalayo nebonakalayo yezinga lokushisa eliphezulu kakhulu kanye nedivayisi yokuvala amandla okuzenzakalelayo lapho uvula umnyango |

| Isistimu yokucima umlilo ezenzakalelayo | Imishini ifakwe i-alamu yokubona ilangabi kanye nesistimu yokucisha umlilo. Lapho umlilo uvela esithandweni ngokusebenzisa isistimu yenzwa yerimothi, isignali ye-alamu izothunyelwa ukuze utshele opharetha ukuthi aqinisekise umlilo nokuthi avule yini isistimu yokucisha umlilo eyimpushana. Impushana eyomile ecisha umlilo ecindezelwe ingashajwa esithandweni. Yenza ukwelashwa kokucisha umlilo kuma-sintered specimens. |

| Ububanzi bewaranti nesikhathi | Isitofu sikagesi sinewaranti yamahhala yonyaka owodwa, kodwa isici sokushisa asikho ngaphansi kwewaranti (sizoshintshwa mahhala uma sonakaliswa ngenxa yokulimala kwemvelo phakathi nezinyanga ezintathu). |

| Izingxenye ezisele ezingahleliwe | Izinto ezimbili zokushisisa, amasethi amabili ezinti, udlawu oluhlikihlayo, kanye namagilavu ashisa kakhulu. |

| Uhlu lokupakisha | Isithando somlilo esisodwa sikagesi, izakhi ezimbili zokufudumeza, amasethi amabili wezinduku , i-pliers eyodwa ye-crucible, i-glove eyodwa yamagilavu aphezulu, incwadi eyodwa yeziqondiso, isitifiketi esisodwa sokuvumelana, umbiko owodwa wokwamukela (umbiko wokuhlolwa kwefekthri), kanye nenothi elilodwa lokulethwa kokuthengisa. |

Idizayini nokusebenza:

Umklamo we-Vacuum Atmosphere I-Heat Treatment Furnace igxile ekhonweni layo lokudala nokugcina umoya ongenalutho noma olawulwayo. Isithando somlilo ngokuvamile sihlanganisa igumbi eliqinile, elivalekile elakhiwe ngensimbi engagqwali noma amanye ama-alloy amelana nokushisa okuphezulu. Ikamelo lifakwe izinto zokushisa ezikwazi ukufinyelela amazinga okushisa aphezulu, ngokuvamile ebangeni lika-1200 ° C kuya ku-1800 ° C, kuye ngokuthi isicelo.

Inqubo yokwelapha ukushisa iqala ngokukhishwa komoya ekamelweni ukuze kufinyelelwe izinga le-vacuum elifunekayo, kusetshenziswa amaphampu e-vacuum asebenza kahle kakhulu. Ngaphandle kwalokho, igumbi lingabuye ligcwaliswe ngegesi ye-inert, njenge-argon noma i-nitrogen, ukudala umkhathi othize. Izinto ezizophathwa zibe sezishisiswe ngenani elilawulwayo kuya kuzinga lokushisa eliqondiwe, libanjwe isikhathi esinqunyiwe, bese lipholiswa, ngokushesha noma kancane, ngokusekelwe ezintweni ezibonakalayo ezidingekayo.

Izinzuzo Zokwelashwa Kokushisa Kwe-Vacuum Atmosphere:

Ukusetshenziswa kwe-vacuum noma umoya olawulwayo phakathi nokwelashwa kokushisa kunikeza izinzuzo ezimbalwa kunezindlela zendabuko:

1. Ukwehliswa kwe-Oxidation kanye Nokususwa kwe-Carburization:

Ngokususa umoya-mpilo endaweni ezungezile, ingcuphe ye-oxidation kanye ne-decarburization iyancishiswa, ilondoloze ubuqotho bendawo yezinto ezibonakalayo kanye nekhwalithi iyonke.

2. Izakhiwo Zemishini Ethuthukisiwe:

Ukwelashwa kokushisa kwe-vacuum kungaholela kuma-microstructures afanayo, okuholela ekuthuthukisweni kwezakhiwo zemishini ezinjengobulukhuni, ukuqina, nokumelana nokukhathala.

3. Ukuqeda Okuhlanzekile Nokukhanyayo:

Izinto ezicutshungulwa endaweni ye-vacuum ngokuvamile ziba nesiphetho esihlanzekile nesigqamile, okunciphisa isidingo sokwelashwa okwengeziwe kwendawo.

4. Ukulawula Okunembile:

Amandla okulawula umkhathi kanye namaphrofayili okushisa ngokunemba okuphezulu avumela ukucushwa kahle kwezakhiwo zezinto ezibonakalayo ukuze kuhlangatshezwane nezidingo ezithile.

Izicelo:

Ukuhlukahluka kwe-Vacuum Atmosphere Heat Treatment Furnaces kuholele ekusetshenzisweni kwazo okuhlukahlukene:

1. Izingxenye ze-Aerospace:

Imboni ye-aerospace idinga izingxenye ezikwazi ukumelana nezimo ezimbi kakhulu. Izingxenye eziphathwa ngokushisa kwe-vacuum zinikeza amandla adingekayo nokuqina ngaphandle kokubeka engcupheni isisindo.

2. Izingxenye Zezimoto:

Izingxenye zezimoto ezisebenza kahle kakhulu, njengamagiya namabheringi, ziyazuza ekuphikiseni ukuguga namandla ahlinzekwa ukwelashwa kokushisa kwe-vacuum.

3. Ukwenza Ithuluzi Nokufa:

Amathuluzi kanye nokufa kudinga ubulukhuni obukhethekile nokuzinza kwe-dimensional, okungafinyelelwa ukwelashwa kokushisa kwe-vacuum ngenkathi kugcinwa ukubekezelelana okuqinile.

4. Amadivayisi Ezokwelapha:

I-biocompatibility kanye nokusebenza kwezifakelo zezokwelapha namadivayisi athuthukiswa ngezinqubo zokwelashwa kokushisa kwe-vacuum eziqinisekisa izindawo ezihlanzekile neziyinyumba.

Isiphetho:

Ukwamukelwa kwe-Vacuum Atmosphere Izithando Zokushisa Zokushisa sekuyinto ebaluleke kakhulu ekuphishekeleni izinto eziphambili. Ikhono layo lokulawula ngokunembile izimo zemvelo ngesikhathi sokwelashwa kokushisa lihumusha ezintweni ezibonakalayo eziphezulu nokusebenza. Njengoba izimboni ziqhubeka nokufuna ikhwalithi ephezulu kanye nezinto ezikhethekile kakhulu, indima yobuchwepheshe bokwelapha ukushisa kwe-vacuum ngokungangabazeki izokhula, ikhuthaze ukusungulwa okuqhubekayo kanye nokusetshenziswa emkhakheni wesayensi yezinto ezibonakalayo.