Izakhiwo Zokukhiqiza Izithandani Ngokuxoshwa

Incazelo

Izakhiwo Zokukhiqiza Izithandani Ngokuxoshwa

Imininingwane

I-1 Uma ukufakwa kokufakelwa kwesithando somkhakha we-metallurgical,

Isimboni se-Foundry 2,

Imikhiqizo ye-3 Ukufakelwa,

Imikhiqizo yezokwelapha ye-4,

| Isilinganiso samanani | KG | 10-50 | 100 | 150 | 250 | 350 | 500 | 750 | 1000 | 1500 |

| amandla Kulinganiselwe ngo- | KW | 50 | 100 | 100 | 130 | 180 | 250 | 450 | 600 | 1000 |

| voltage Input | V | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380-2 | 380-2 |

| Umthamo wokuguqula | I-KVA | 60 | 120 | 120 | 150 | 200 | 315 | 500 | 800 | 1500 |

| Out voltage | V | 750 | 750 | 750 | 750 | 750 | 750 | 1500 | 2500 | 2500 |

| Imvamisa yokuphuma | KHZ | 2.5 | 1 | 1 | 1 | 1 | 1 | 1 | 0.8 | 0.8 |

| Isikhathi sokukha amanzi | min | 10-40 | 10-40 | 20-50 | 20-50 | 20-50 | 20-50 | 25-55 | 30-60 | 30-60 |

| Ukusetshenziswa kwamandla (insimbi) | Kw.h / T | 900 | 850 | 850 | 800 | 750 | 700 | 650 | 620 | 600 |

| Ukusetshenziswa kwamandla (iron cast) | Kw.h / T | 850 | 800 | 800 | 750 | 700 | 650 | 630 | 610 | 580 |

| Ukusetshenziswa kwamandla (ithusi) | Kw.h / T | 500 | 500 | 500 | 490 | 480 | 480 | 400 | 390 | 380 |

| Ukusetshenziswa kwamandla (aluminium) | Kw.h / T | 780 | 750 | 750 | 710 | 670 | 620 | 600 | 570 | 540 |

| Ukupholisa Amanzi | T / h | 3 | 5 | 5 | 7 | 8 | 10 | 15 | 18 | 25 |

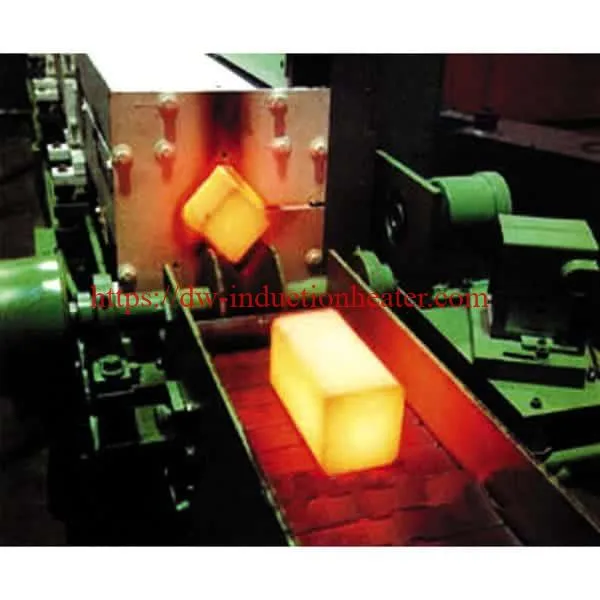

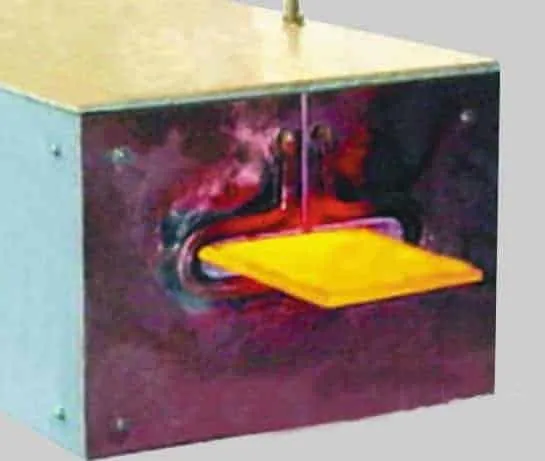

1. Isizukulwane esisha somphumela wokonga amandla we-IF induction furnace sinomthelela omncane wamandla, ekwakheni nasekuncibilikeni ukusebenza okuphezulu, ukufana kokushisa, ukulahleka kwe-oxidation kokuncane, okulula ukuwulawula, umphumela wokufakwa kwe-thermal muhle njalonjalo. UMA uhlelo lokulawulwa kwesithando somlilo lisebenzisa i-silicon-elawulwa yi-AC-DC yokuguqula amandla, ukulawula okungadluliseli kwedijithali, ngokuthembeka okuphezulu kanye nemvamisa yokusebenza ephezulu yamandla wokulwa nokuqhudelana ngokulandela ngomkhondo okuzenzakalelayo, izinqubo zomsebenzi ngaphandle kokungenelela komuntu, zihambisana ngokuzenzakalela nomthwalo futhi amandla. Ngokweqile kwamanje, ngaphezu kwamandla kagesi, isigaba sokuntuleka, amandla wokuvikela umfutho wamanzi awanele avumela amadivayisi wanoma yikuphi ukwehluleka okwenzeka ngesikhathi sokusebenza ngeke alimaze izinto, kunciphise ukusetshenziswa kwemishini nezindleko zokulungisa. Ngokushisa okungena ngaphakathi, ukuncibilika, ukubopha, ukwelashwa kokushisa, ukuminyanisa, njengokuxhasa ukusetshenziswa kwe-crystal eyodwa. Ingakhuphula uhlelo lwempendulo yezinga lokushisa, ukwakheka kohlelo lokushisa lokuvala okuzenzakalelayo lokuvala okuzenzakalelayo: kwandisa izinga lokushisa lokwehlukanisa okunamathiselwe emishini, ukufeza kuphela ukuthumela izinga lokushisa elifanelekayo lesiteshi sokusebenzela. Ukwengezwa kwezindawo zokuxhumana ezikhethekile, yamukela i-PLC noma "isikhombimsebenzisi somshini womuntu", isistimu yokulawulwa kwemishini yezimboni kanye nohlelo lokushisa ukufezekisa ukulawula okuhlakaniphile, okuhambisana nethuluzi lokulawula ukushisa elihlakaniphile lokulawulwa kokushisa okunembile kokuqaliswa kokuncibilikisa nokwakha okushisayo.

2 isithando somlilo sakhiwe:

NOMA ukulawula amandla, amakhemikhali anekhono, isithando somzimba (i-aluminium noma insimbi), imishini (hydraulic) Faka imishini yokushisa amanzi, umsakazo wamanzi, isikhunta se-crucible (i-grapheite crucible, i-crucible iron), izintambo ezihlile amanzi, izixhumi ze-Copper

I-3 esekela imishini yokuzikhethela:

Kumzila wezinguquko, i-high voltage switchboard, uhlelo lokupholisa amanzi, ushintshe isithando somlilo, ukuvuza i-furnace device i-alamu