Kuyini ukukhishwa kwe-induction?

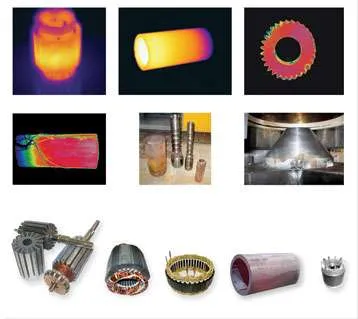

Ngokufakwa kwe-induction ukushisa kufakwa ngogesi ku-workpiece. Ijubane nokunemba

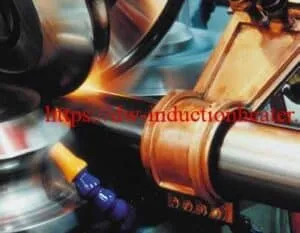

Welding induction yenza kube kuhle ekushiseni komphetho kwamashubhu namapayipi. Kule nqubo, amapayipi adlulisa ikhoyili yokungeniswa ngejubane elikhulu. Njengoba benza kanjalo, imiphetho yabo iyashiswa bese iyakhanywa ndawonye ukuze yakhe umsila we-weld longitudinal. Ukushiswa kwe-induction kufanelekile ikakhulukazi ekukhiqizeni okuphezulu. Ama-welding wokungeniswa nawo angafakwa emakhanda oxhumana nawo, uwaguqule abe

izinhlelo ezimbili zokulanda izinhloso.

Ziyini izinzuzo?

Ukushisela okuzenzakalelayo kwe-induction okuzenzakalelayo kuyinkqubo ethembekile, ephezulu kakhulu. Ukusetshenziswa kwamandla okuphansi nokusebenza kahle kwezinhlelo zokushisela ze-DAWEI kunciphisa izindleko. Ukulawulwa kwabo nokuphindeka kwabo kunciphisa udoti. Amasistimu ethu abuye aguquguquke — ukufaniswa kokulayishwa okuzenzakalelayo kuqinisekisa amandla okukhipha okugcwele kububanzi obuhlukahlukene bamashubhu. Futhi ukunyathela kwabo okuncane kwenza kube lula ukuhlanganisa noma ukuphinda kwenziwe kabusha emigqeni yokukhiqiza.

Kuphi lapho kusetshenziswa khona?

I-induction welding isetshenziswa embonini yethubhu nepayipi ekushiseni kwe-longitudinal yensimbi engagqwali (magnetic futhi non-magnetic), i-aluminium, i-low-carbon ne-highstrength low-alloy (HSLA) steels nezinye izinto eziningi ezihamba kahle

materials.

Kungani I-Induction Heating iwubuchwepheshe obuluhlaza bekusasa

Kungani I-Induction Heating iwubuchwepheshe obuluhlaza bekusasa? Njengoba umhlaba uqhubeka nokugxila emandleni esimeme kanye nokunciphisa ukukhishwa kwekhabhoni, izimboni zifuna izindlela ezintsha zokwenza izinqubo zazo zivumelane nemvelo. Obunye ubuchwepheshe obuthembisayo ukushisisa kwe-induction, okusebenzisa amandla kazibuthe ukukhiqiza ukushisa ngaphandle kwesidingo sezibaseli ezimbiwa phansi noma ... Funda kabanzi