I-High Frequency Induction Seam Welding Tube kanye nezixazululo zepayipi

Kuyini ukukhishwa kwe-induction?

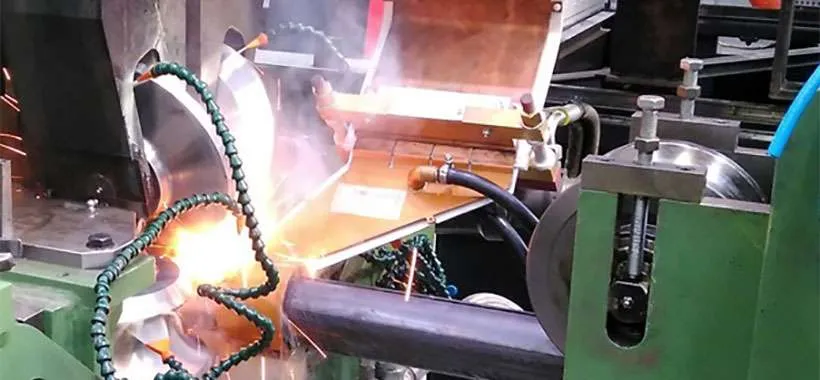

Nge-induction welding, ukushisa kudonswa ngozibuthe endaweni yokusebenza. Ijubane nokunemba kwe-induction welding kuyenza ilungele ukushisela onqenqemeni kwamashubhu namapayipi. Kule nqubo, amapayipi adlula ikhoyili yokungeniswa ngesivinini esikhulu. Njengoba benza kanjalo, imiphetho yabo iyafudumala, bese iyampintshana ukuze yenze umthungo we-weld we-longitudinal. I-induction welding ifaneleka ikakhulukazi ukukhiqizwa kwevolumu ephezulu. Ama-welders e-induction angabuye afakwe amakhanda okuxhumana, awaguqule abe izinhlelo ezimbili zokushisela.

Nge-induction welding, ukushisa kudonswa ngozibuthe endaweni yokusebenza. Ijubane nokunemba kwe-induction welding kuyenza ilungele ukushisela onqenqemeni kwamashubhu namapayipi. Kule nqubo, amapayipi adlula ikhoyili yokungeniswa ngesivinini esikhulu. Njengoba benza kanjalo, imiphetho yabo iyafudumala, bese iyampintshana ukuze yenze umthungo we-weld we-longitudinal. I-induction welding ifaneleka ikakhulukazi ukukhiqizwa kwevolumu ephezulu. Ama-welders e-induction angabuye afakwe amakhanda okuxhumana, awaguqule abe izinhlelo ezimbili zokushisela.

Yiziphi izinzuzo ze-induction Seam welding?

I-automated induction longitudinal welding iyinqubo ethembekile, ehamba phambili. Ukusetshenziswa kwamandla okuphansi nokusebenza kahle okuphezulu kwe I-HLQ Induction welding systems ukunciphisa izindleko. Ukulawuleka kwazo nokuphindaphindeka kunciphisa izinsalela. Amasistimu ethu nawo ayavumelana nezimo—ukufanisa umthwalo okuzenzakalelayo kuqinisekisa amandla aphelele aphumayo kunhlobonhlobo yamasayizi wamashubhu. Futhi izinyathelo zabo ezincane zibenza kube lula ukuhlanganisa noma ukubuyisela emigqeni yokukhiqiza.

I-automated induction longitudinal welding iyinqubo ethembekile, ehamba phambili. Ukusetshenziswa kwamandla okuphansi nokusebenza kahle okuphezulu kwe I-HLQ Induction welding systems ukunciphisa izindleko. Ukulawuleka kwazo nokuphindaphindeka kunciphisa izinsalela. Amasistimu ethu nawo ayavumelana nezimo—ukufanisa umthwalo okuzenzakalelayo kuqinisekisa amandla aphelele aphumayo kunhlobonhlobo yamasayizi wamashubhu. Futhi izinyathelo zabo ezincane zibenza kube lula ukuhlanganisa noma ukubuyisela emigqeni yokukhiqiza.

Isetshenziswa kuphi i-induction seam welding?

I-induction welding isetshenziswa embonini ye-tube kanye nepayipi ye-longitudinal welding yensimbi engagqwali (magnetic and non-magnetic), i-aluminium, i-low-carbon kanye ne-high-strength low-alloy (HSLA) izinsimbi nezinye izinto eziningi zokuqhuba.

I-High Frequency Induction Seam Welding

I-High Frequency Induction Seam Welding

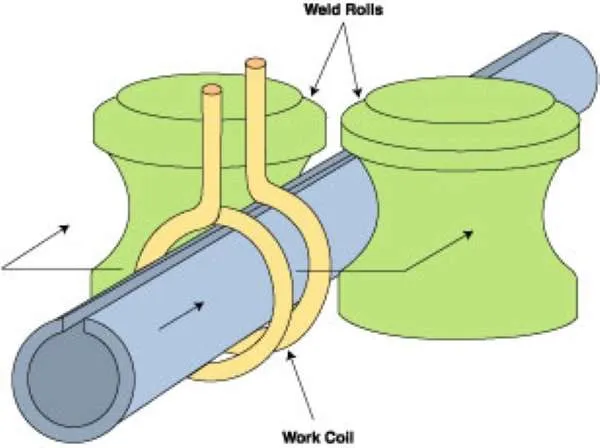

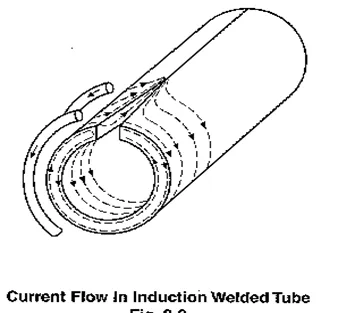

Enqubweni ye-high frequency induction tube welding, i-high frequency current ifakwa kuthubhu ye-seam evulekile ngekhoyili ye-induction etholakala ngaphambi (phezulu ukusuka) endaweni ye-weld, njengoba kuboniswe ku-Fig. 1-1. Amaphethelo eshubhu ahlukaniswa ngokwehlukana lapho edlula kukhoyili, enze i-vee evulekile lapho i-apex yayo ingaphambi kancane kwephoyinti lokushisela. Ikhoyili ayixhumani neshubhu.

Ikhoyili isebenza njengesisekelo se-high frequency transformer, futhi ithubhu lomthungo elivulekile lisebenza njenge-turn-turn yesibili. Njengokwezinhlelo zokusebenza zokushisa zokungeniswa okujwayelekile, indlela yamanje eyenziwe endaweni yokusebenza ijwayele ukuhambisana nokuma kwekhoyili yokungeniswa. Iningi lamandla akhona liqeda indlela yalo ezungeza umucu owenziwe ngokugeleza emaphethelweni futhi liminyene lizungeze umkhawulo wokuvuleka okumise okwe-vee emgqeni.

Ukuminyana kwamanje kwefrikhwensi ephezulu kuphezulu emaphethelweni aseduze ne-apex kanye naku-apex uqobo. Ukushisisa okusheshayo kwenzeka, okwenza ukuthi imiphetho ibe kuzinga lokushisa lokushisela lapho ifika phezulu. I-pressure rolls iphoqa imiphetho eshisayo ndawonye, iqedela ukushisela.

Imvamisa ephezulu ye-welding current enesibopho sokushisa okugxilile emaphethelweni e-vee. Inenye inzuzo, okungukuthi ingxenye encane kuphela yengqikithi yamanje ethola indlela yayo eduze nomugqa owenziwe. Ngaphandle uma ububanzi beshubhu buncane kakhulu uma buqhathaniswa nobude be-vee, yamanje ikhetha indlela ewusizo emaphethelweni eshubhu elenza i-vee.

Umphumela Wesikhumba

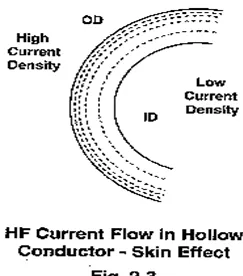

Inqubo yokushisela i-HF incike ezintweni ezimbili ezihlotshaniswa ne-HF yamanje - I-Skin Effect kanye ne-Proximity Effect.

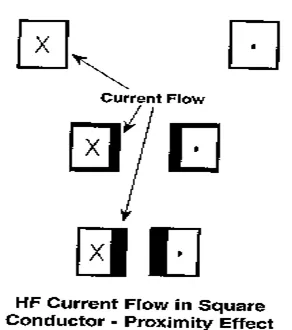

Umthelela wesikhumba ukuthambekela kwe-HF yamanje ukugxila ebusweni bomqhubi.

Lokhu kuboniswe kumfanekiso 1-3, obonisa i-HF yamanje egeleza kumakhondaktha angawodwana anomumo ohlukahlukene. Cishe wonke umsinga ugeleza esikhumbeni esingashoni eduze nendawo.

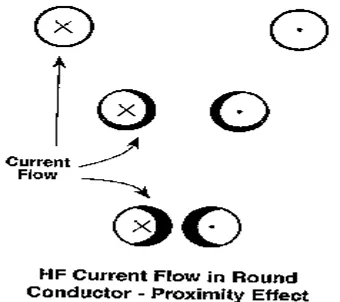

Umphumela Wokusondela

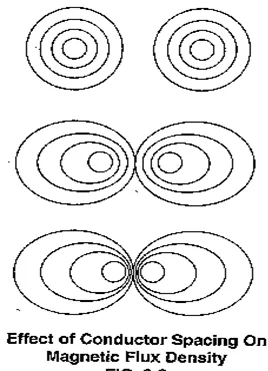

Isenzakalo sesibili sikagesi esibalulekile enqubweni yokushisela ye-HF i-proximity effect. Lona ukuthambekela kwe-HF yamanje ku-conductor ye-go/return ukuze igxilise ezingxenyeni zezindawo zekhondatha eziseduze kwesinye. Lokhu kuboniswa kuFig. 1-4 kuya ku-1-6 ukuze uthole umumo we-conductor oyindilinga nesikwele kanye nezikhala.

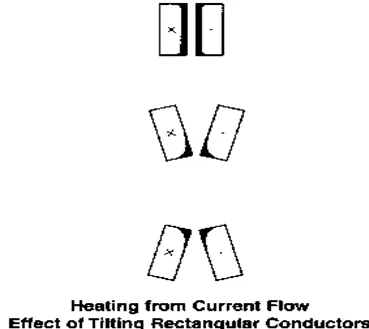

I-physics ngemuva komphumela wokusondelana incike eqinisweni lokuthi inkambu kazibuthe ezungeze abaqhubi be-go/return igxile kakhulu endaweni ewumngcingo phakathi kwabo kunakwenye indawo (Fig. 1-2). Imigqa yamandla kazibuthe inesikhala esincane futhi isiminyaniswe eduze. Lokhu kulandela ukuthi umphumela wokusondelana unamandla uma amakhondatha esondelene ndawonye. Iphinde ibe namandla uma izinhlangothi zibhekene zibanzi.

Umdwebo 1-6 ubonisa umthelela wokutshekisa amakhondatha amabili asondelene we-rectangular go/return ngokuhlobene. Ukugxila kwamanje kwe-HF kukhulu kakhulu emakhoneni aseduze ndawonye futhi kuncipha kancane kancane ebusweni obuphambukisayo.

Ukusebenzelana kukagesi kanye neMechanical

Kunezindawo ezimbili ezijwayelekile okufanele zilungiswe ukuze kutholwe izimo ezingcono kakhulu zikagesi:

- Okokuqala ukwenza konke okusemandleni ukukhuthaza inani elikhulu le-HF yamanje ngangokunokwenzeka ukuthi ligeleze endleleni ewusizo ku-vee.

- Okwesibili ukwenza konke okusemandleni ukwenza imiphetho ihambisane ku-vee ukuze ukushisa kube okufanayo kusuka ngaphakathi kuya ngaphandle.

Inhloso (1) ngokusobala incike ezintweni zikagesi ezifana nokuklanywa nokubekwa kwezinto ezithinta insimbi noma ikhoyili kanye nasocingweni olubambayo lwamanje olufakwe ngaphakathi kweshubhu. Umklamo uthintwa yisikhala esibonakalayo esitholakala emshinini wokugaya, kanye nokuhlelwa nobukhulu bemiqulu yokushisela. Uma i-mandrel izosetshenziselwa ngaphakathi scarfing noma rolling, kuthinta impeder. Ngaphezu kwalokho, inhloso (1) incike kubukhulu be-vee ne-engeli yokuvula. Ngakho-ke, nakuba (1) iwugesi ngokuyisisekelo, ihambisana eduze nemishini yokugaya.

Inhloso (2) incike ngokuphelele ezintweni eziwumshini, njengokuma kweshubhu elivulekile kanye nesimo sonqenqema somugqa. Lezi zingathintwa yilokho okwenzeka emuva kumaphasi okugaya isigayo ngisho naku-slitter.

Ukushisela kwe-HF kuyinqubo ye-electro-mechanical: Ijeneretha ihlinzeka ngokushisa emaphethelweni kodwa amaroli acindezelayo enza i-weld. Uma imiphetho ifinyelela izinga lokushisa elifanele futhi usenama-welds anesici, amathuba mahle kakhulu ukuthi inkinga isendaweni yokugaya noma ezintweni ezibonakalayo.

Izici Zemishini Ethize

Ekuhlaziyeni kokugcina, okwenzeka ku-vee kubaluleke kakhulu. Konke okwenzeka lapho kungaba nomthelela (okuhle noma omubi) kukhwalithi ye-weld nesivinini. Ezinye zezinto okufanele zicatshangelwe ku-vee yilezi:

- Ubude be-vee

- Idigri yokuvula (i-engeli ye-vee)

- Ibanga elingakanani ngaphambi komugqa ophakathi nendawo we-weld roll eqala ukuthintana

- Ukuma nesimo semiphetho ye-strip ku-vee

- Ukuthi amaphethelo e-strip ahlangana kanjani - noma ngasikhathi sinye ugqinsi lwawo - noma kuqala ngaphandle - noma ngaphakathi - noma nge-burr noma i-sliver

- Ukuma komugqa owenziwe ku-vee

- Ukungaguquguquki kwazo zonke izilinganiso ze-vee kufaka phakathi ubude, i-engeli yokuvula, ukuphakama kwemiphetho, ukujiya kwemiphetho

- Ukuma koxhumana nabo be-welding noma ikhoyili

- Ukubhaliswa kwemiphetho ye-strip ehlobene lapho ihlangana ndawonye

- Ingakanani impahla ekhanywa ngaphandle (ububanzi be-strip)

- Ishubhu noma ipayipi kufanele libe ubukhulu obungakanani ukuze kubekwe usayizi

- Mangakanani amanzi noma isigayo sokupholisa esithela ku-vee, kanye nesivinini saso sokungena

- Ukuhlanzeka kwesipholisi

- Ukuhlanzeka kwe-strip

- Ukuba khona kwezinto zangaphandle, njengesikali, ama-chips, ama-slivers, okufakiwe

- Ukuthi i-steel skelp ivela ku-rimmed noma ensimbi ebulewe

- Ukuthi i-welding in the rim of rimmed steel noma i-skelp ye-slit eminingi

- Ikhwalithi ye-skelp - kungakhathaliseki ukuthi ivela kunsimbi elaminethiwe - noma insimbi enezintambo eziningi kakhulu kanye ne-inclusions (insimbi "engcolile")

- Ukuqina kanye nezakhiwo ezibonakalayo ze-strip material (ethinta inani le-spring back kanye nengcindezi yokuminyanisa edingekayo)

- Ukufana kwejubane le-Mill

- Ikhwalithi yokusika

Kusobala ukuthi okuningi okwenzeka ku-vee kuwumphumela walokho osekwenzekile - kungaba emshinini uqobo noma nangaphambi kokuba i-strip noma i-skelp ingene emshinini.

I-High Frequency Vee

Inhloso yalesi sigaba ukuchaza izimo ezifanele ku-vee. Kwaboniswa ukuthi imiphetho ehambisanayo inikeza ukushisa okufanayo phakathi kwangaphakathi nangaphandle. Izizathu ezengeziwe zokugcina imiphetho ihambisana ngangokunokwenzeka zizonikezwa kulesi sigaba. Ezinye izici ze-vee, njengendawo ye-apex, i-engeli yokuvula, kanye nokuzinza ngenkathi isebenza.

Izigaba zakamuva zizonikeza izincomo ezithile ezisekelwe ekuhlangenwe nakho kwasensimini ukuze kuzuzwe izimo ze-vee ezifiselekayo.

I-Apex njenge-Near Welding Point ngangokunokwenzeka

Umdwebo 2-1 ubonisa iphoyinti lapho amaphethelo ahlangana khona (okungukuthi, i-apex) ukuthi ibe phezulu nomfula omaphakathi womugqa wokucindezela. Lokhu kungenxa yokuthi inani elincane lezinto liyakhanywa ngesikhathi sokushisela. I-apex iqeda isekethe kagesi, futhi i-HF yamanje esuka kolunye unqenqema iyajika iphinde ibuyele emuva ihambisana nolunye.

Esikhaleni esiphakathi kwe-apex kanye ne-pressure roll centerline akukho okunye ukufudumeza ngoba akukho okugelezayo kwamanje, futhi ukushisa kushabalalisa ngokushesha ngenxa ye-gradient yokushisa ephezulu phakathi kwemiphetho eshisayo nensalela yeshubhu. Ngakho-ke, kubalulekile ukuthi i-apex ibe seduze ngangokunokwenzeka ne-weld roll centerline ukuze izinga lokushisa lihlale liphakeme ngokwanele ukwenza i-weld enhle lapho kufakwa ingcindezi.

Lokhu kususwa kokushisa okusheshayo kunesibopho sokuthi uma amandla e-HF ephindwe kabili, isivinini esifinyelelekayo singaphezu kokuphindwe kabili. Isivinini esiphezulu esibangelwa amandla aphezulu sinikeza isikhathi esincane sokuthi ukushisa kuhambe. Ingxenye enkulu yokushisa okwakhiwa ngogesi emaphethelweni iba usizo, futhi ukusebenza kahle kuyanda.

Iziqu zeVee Opening

Ukugcina i-apex iseduze ngangokunokwenzeka ku-centerline ye-weld pressure kuveza ukuthi ukuvuleka kwe-vee kufanele kube banzi ngangokunokwenzeka, kodwa kunemikhawulo esebenzayo. Esokuqala yikhono eliphathekayo lesigayo sokubamba imiphetho ivuliwe ngaphandle kokushwabana noma ukulimala komphetho. Okwesibili ukuncishiswa komphumela wokusondelana phakathi kwemiphetho emibili uma ihlukene kakhulu. Kodwa-ke, ukuvuleka okuncane kakhulu kwe-vee kungase kukhuthaze ukugoqa ngaphambi kwesikhathi kanye nokuvala ngaphambi kwesikhathi kwe-vee okubangela ukukhubazeka kokushisela.

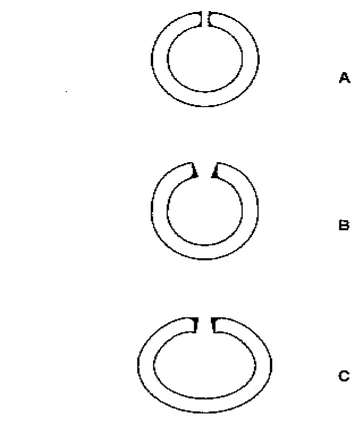

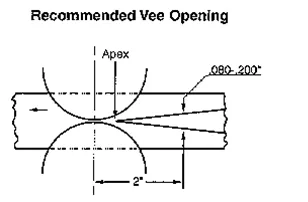

Ngokusekelwe kokuhlangenwe nakho kwenkundla, ukuvulwa kwe-vee ngokuvamile kuyanelisa uma isikhala esiphakathi kwamaphethelo endaweni engu-2.0″ phezulu komfula ukusuka ku-weld roll centerline siphakathi kuka-0.080″(2mm) no-.200″(5mm) okunikeza i-engeli ehlanganisiwe ephakathi kuka-2° kanye 5° ngensimbi ye-carbon. I-engeli enkudlwana iyathandeka kunsimbi engagqwali nezinsimbi ezingezona ayoni.

Kunconywe ukuvulwa kwe-Vee

I-Parallel Edges Gwema i-Double Vee

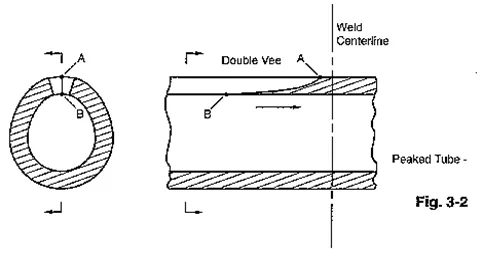

Umdwebo 2-2 ubonisa ukuthi uma amaphethelo angaphakathi ahlangana kuqala, kukhona ama-vees amabili - enye ingaphandle ne-apex yayo ku-A - enye ingaphakathi ne-apex yayo ku-B. I-vee yangaphandle yinde futhi i-apex yayo eduze kwe-pressure roll centerline.

Ku-Fig. 2-2 i-HF current ikhetha i-vee yangaphakathi ngoba imiphetho isondelene kakhulu. I-current ijika ibe ngu-B. Phakathi kuka-B nendawo yokushisela, akukho ukushisisa futhi imiphetho iphola ngokushesha. Ngakho-ke, kuyadingeka ukushisisa ishubhu ngokwandisa amandla noma ukunciphisa isivinini ukuze izinga lokushisa endaweni yokushisela libe phezulu ngokwanele ukuze kube nokushisela okwanelisayo. Lokhu kuba kubi nakakhulu ngoba imiphetho yangaphakathi izobe ishise kakhulu kunangaphandle.

Ezimweni ezimbi kakhulu, i-double vee ingabangela ukuconsa ngaphakathi kanye ne-weld ebandayo ngaphandle. Konke lokhu bekungagwenywa uma imiphetho ibihambisana.

I-Parallel Edges Yehlisa Ukufakwa

Enye yezinzuzo ezibalulekile zokushisela i-HF yiqiniso lokuthi isikhumba esincane sincibilika ebusweni bamaphethelo. Lokhu kwenza ama-oxide nezinye izinto ezingafuneki zikhanywe, zinikeze ukushisela okuhlanzekile, kwekhwalithi ephezulu. Ngamachopho ahambisanayo, ama-oxide akhanywa kuzo zombili izinkomba. Akukho lutho endleleni yabo, futhi akudingeki bahambe ngaphezu kwesigamu sodonga.

Uma amaphethelo angaphakathi ahlangana kuqala, kuba nzima ukuthi ama-oxide akhishwe. Ku-Fig. 2-2 kukhona umkhombe phakathi kwe-apex A kanye ne-apex B esebenza njenge-crucible yokuqukatha izinto zangaphandle. Lokhu okubalulekile kuntanta ensimbi encibilikisiwe eduze nemiphetho yangaphakathi eshisayo. Phakathi nesikhathi sokuminyana ngemva kokudlula i-apex A, ayikwazi ukudlula ngokuphelele emaphethelweni angaphandle apholile, futhi ingavaleleka kusixhumi esibonakalayo esishiselayo, yenze okufakiwe okungafuneki.

Kube nezimo eziningi lapho amaphutha okushisela, ngenxa yokufakwa eduze nangaphandle, alandelelwa emaphethelweni angaphakathi ahlangana ngokushesha kakhulu (okungukuthi, ishubhu eliphakeme). Impendulo iwukushintsha nje ukwakheka ukuze imiphetho ihambisane. Ukungakwenzi lokho kungase kuphazamise ukusetshenziswa kwezinzuzo ezibaluleke kakhulu ze-HF welding.

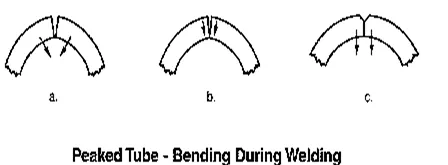

I-Parallel Edges Yehlisa Ukunyakaza Okuhlobene

Umdwebo 2-3 ubonisa uchungechunge lwezigaba eziphambene okungenzeka zithathwe phakathi kuka-B no-A ku-Fig. 2-2. Lapho imiphetho yangaphakathi yeshubhu enezinga eliphakeme ixhumana kuqala, inamathela ndawonye (Fig. 2-3a). Ngokushesha kamuva (Fig. 2-3b), ingxenye ebambekile igoba. Amakhona angaphandle ahlangana njengokungathi amaphethelo ahlanganiswe ngaphakathi (Fig. 2-3c).

Lokhu kugoba kwengxenye engaphakathi yodonga ngesikhathi sokushisela akulimazi kangako uma kushiselwa insimbi kunalapho kushiselwa izinto ezifana ne-aluminium. Insimbi inebanga lokushisa lepulasitiki elibanzi. Ukuvimbela ukunyakaza okuhlobene kwalolu hlobo kuthuthukisa ikhwalithi yokushisela. Lokhu kwenziwa ngokugcina imiphetho ihambisana.

I-Parallel Edges Yehlisa Isikhathi Sokushisela

Futhi ngokubhekisela ku-Fig. 2-3, inqubo yokushisela iyenzeka kusukela ku-B kuya ku-weld roll centerline. Kukulesi sikhungo lapho ingcindezi enkulu ekugcineni ikhishwa futhi ukushisela kuqediwe.

Ngokuphambene, lapho amaphethelo ehlangana ngokuhambisana, awaqali ukuthinta aze okungenani afinyelele ePhoyinti A. Cishe ngokushesha, kusetshenziswa ukucindezela okukhulu. Imiphetho ehambisanayo ingase yehlise isikhathi sokushisela cishe ngo-2.5 kuya ku-1 noma ngaphezulu.

Ukuhlanganisa imiphetho ngokuhambisana kusebenzisa lokho abakhandi bensimbi abebelokhu bekwazi: Shaya ngenkathi insimbi ishisa!

I-Vee njengomthwalo kagesi ku-Generator

Enqubweni ye-HF, lapho kusetshenziswa izivimbela kanye neziqondiso zokuthunga njengoba kunconyiwe, indlela ewusizo emaphethelweni e-vee ihlanganisa isamba sesekhethi yomthwalo ebekwa kujeneretha wamafrikhwensi aphezulu. I-current ekhishwe ku-generator yi-vee incike ekuphazamisekeni kukagesi kwe-vee. Le impedance, nayo, incike kubukhulu be-vee. Njengoba i-vee inwetshiwe (othintana nabo noma ikhoyili ibuyiselwe emuva), i-impedance iyanda, futhi yamanje ivame ukuncipha. Futhi, wamanje oncishisiwe kufanele manje ushise insimbi eyengeziwe (ngenxa ye-vee ende), ngakho-ke, amandla engeziwe ayadingeka ukubuyisela indawo yokushisela ekushiseni okushiselayo. Njengoba ubukhulu bodonga bukhuphuka, i-impedance iyancipha, futhi okwamanje ivame ukwanda. Kudingeka ukuthi i-impedance ye-vee isondele ngokunengqondo kunani lokuklama uma amandla aphelele azothathwa kujeneretha yefrikhwensi ephezulu. Njengomucu okwi-bulb, amandla adonswayo ancike ekutheni amandla kagesi asetshenziswa kanjani, hhayi kusayizi wesiteshi esiphehlayo.

Ngenxa yezizathu zikagesi, ngakho-ke, ikakhulukazi uma kufunwa ukukhishwa okugcwele kwejeneretha ye-HF, kuyadingeka ukuthi ubukhulu be-vee bunconywe.

Ukwakha Amathuluzi

Ukwakhiwa Kuthinta Ikhwalithi Ye-Weld

Njengoba sekuchaziwe kakade, impumelelo ye-HF yokushisela incike ekutheni isigaba sokwakha siletha imiphetho engaguquki, engena-sliver, futhi ehambisanayo ku-vee. Asizami ukuncoma ukwakhiwa kwamathuluzi anemininingwane yawo wonke ukwakheka nosayizi wesigayo, kodwa siphakamisa imibono ethile mayelana nezimiso ezijwayelekile. Lapho izizathu ziqondwa, okunye kuwumsebenzi oqonde phambili wabaklami bama-roll. Ukwakhiwa kwamathuluzi okulungile kuthuthukisa ikhwalithi yokushisela futhi kwenza umsebenzi womsebenzisi ube lula.

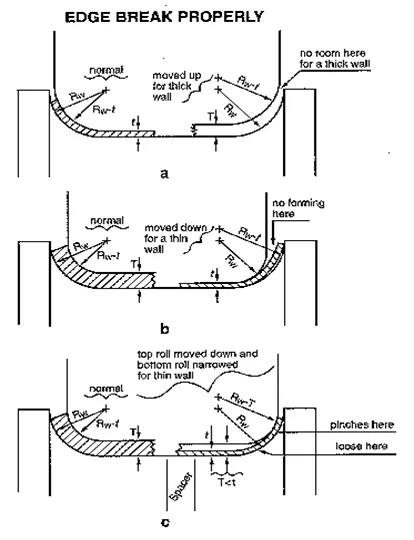

Kunconyiwe Ukuphulwa Kwe-Edge

Sincoma ukuphulwa konqenqema okuqondile noma okulungisiwe. Lokhu kunikeza indawo ephezulu yeshubhu irediyasi yayo yokugcina ekudluleni okukodwa noma okubili kokuqala. Kwesinye isikhathi ishubhu eludongeni elincanyana kwakheka ngokweqile ukuvumela i-springback. Ama-fin pass akumele kuthenjelwe kuwo ukwenza le radiyasi. Azikwazi ukumila ngokweqile ngaphandle kokulimaza imiphetho ukuze zingaphumi zihambisana. Isizathu salesi sincomo siwukuthi imiphetho izohambisana ngaphambi kokuba ifike kuma-weld rolls - okungukuthi, ku-vee. Lokhu kuyahluka ekusebenzeni okuvamile kwe-ERW, lapho ama-electrode amakhulu ayindilinga kufanele asebenze njengamadivayisi amanje aphezulu futhi ngesikhathi esifanayo namaroli ukuze akhe imiphetho iye phansi.

I-Edge Break ngokumelene ne-Center Break

Abasekeli be-center breaking bathi ama-center-break rolls angakwazi ukuphatha ububanzi bosayizi, okwehlisa i-inventory yamathuluzi kanye nokunciphisa isikhathi sokushintsha kwe-roll. Lena impikiswano yezomnotho evumelekile enemishini yokugaya enkulu lapho amaroli emakhulu futhi ebiza. Kodwa-ke, le nzuzo ishintshile ngokwengxenye ngoba ngokuvamile idinga amaroli aseceleni noma uchungechunge lwamaroli ayisicaba ngemva kwe-fin pass yokugcina ukuze kugcinwe imiphetho iphansi. Kufika okungenani ku-6 noma 8″ OD, ukuphuka komphetho kunenzuzo enkulu.

Lokhu kuyiqiniso naphezu kweqiniso lokuthi kuyafiseleka ukusebenzisa amaroli ahlukene aphezulu ezindongeni eziwugqinsi kunodonga oluncane. Umdwebo 3-1a ubonisa ukuthi umqulu ongaphezulu oklanyelwe udonga oluncane aluvumeli indawo eyanele ezinhlangothini zezindonga ezinkulu. Uma uzama ukuzungeza lokhu ngokusebenzisa umqulu ongaphezulu owumngcingo ngokwanele ukuba ube umucu owugqinsi ngaphezu kobubanzi obubanzi bogqinsi, uzoba senkingeni ekugcineni kobubanzi njengoba kusikiselwe ku-Fig. 3-1b. Izinhlangothi zomugqa ngeke zifakwe futhi ukuphulwa konqenqema ngeke kuphelele. Lokhu kubangela ukuthi i-seam igingqike ukusuka kolunye uhlangothi kuya kolunye kuma-weld rolls - okungafuneki kakhulu ekushiseleni okuhle.

Enye indlela esetshenziswa ngezinye izikhathi kodwa esingayincomi ezigayweni ezincane, ukusebenzisa umqulu ongaphansi owakhelwe phezulu onezikhala phakathi nendawo. I-spacer emaphakathi ezacile kanye nesikhala sangemuva esijiyile sisetshenziswa uma usebenzisa udonga oluncane. Idizayini ye-roll yale ndlela iwukuyekethisa okungcono kakhulu. Umdwebo 3-1c ubonisa ukuthi kwenzekani lapho umqulu ongaphezulu uklanyelwe udonga oluwugqinsi futhi umugqa ongezansi uncishiswa ngokufaka ama-spacers ukuze kuhambe udonga oluncane. Umucu uncinzwa eduze kwemiphetho kodwa ukhululekile phakathi nendawo. Lokhu kuvame ukubangela ukungazinzi emshinini wokugaya, okuhlanganisa ne-welding vee.

Enye ingxabano iwukuthi ukuphulwa konqenqema kungabangela ukubopha. Lokhu akunjalo uma ingxenye yoguquko ifakwe ngendlela efanele futhi ilungiswa futhi ukwakheka kusatshalaliswa ngendlela efanele eduze kwesigayo.

Intuthuko yakamuva kubuchwepheshe bokwakha ikheji elawulwa ngekhompuyutha iqinisekisa imiphetho eyisicaba, ehambisanayo kanye nezikhathi zokushintsha ngokushesha.

Ngokuhlangenwe nakho kwethu, umzamo owengeziwe wokusebenzisa i-edge breaking efanele ukhokha kahle ekukhiqizeni okuthembekile, okungaguquki, okusebenziseka kalula, okuphezulu.

I-Fin Passes Iyahambisana

Ukuqhubekela phambili kuma-fin pass kufanele kuholele ngokushelelayo esimweni sokugcina esinconywe ngaphambilini. I-fin pass ngayinye kufanele yenze cishe inani elifanayo lomsebenzi. Lokhu kugwema ukulimaza amaphethelo ku-fin pass esebenze kakhulu.

Ama-Weld Rolls

Ama-Weld Rolls nama-Last Fin Rolls ahlobene

Ukuthola imiphetho ehambisanayo ku-vee kudinga ukuhlotshaniswa komklamo wama-fin pass rolls nama-weld rolls. Umhlahlandlela womthungo kanye nanoma imaphi ama-side rolls angasetshenziswa kule ndawo awokuqondisa kuphela. Lesi sigaba sichaza imiklamo ye-weld roll enikeze imiphumela emihle kakhulu ekufakweni okuningi futhi ichaza idizayini yokugcina ye-finpass ukufanisa le miklamo ye-weld roll.

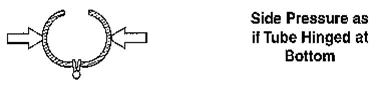

Okuwukuphela komsebenzi we-weld rolls ku-HF welding ukuphoqa imiphetho evuthayo kanye nengcindezi eyanele yokwenza i-weld enhle. Idizayini ye-fin roll kufanele ilethe i-skelp eyakhiwe ngokuphelele (kuhlanganise ne-radius eduze nemiphetho), kodwa ivuleke phezulu kuma-weld rolls. Ukuvuleka kutholakala njengokungathi ishubhu elivalwe ngokuphelele lenziwe ngama-halves amabili axhunywe ihinge yepiyano phansi futhi avele ahlakazeke phezulu (Fig. 4-1). Lo mklamo we-fin roll ufeza lokhu ngaphandle kwe-concavity engathandeki phansi.

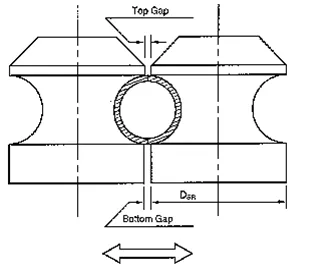

Ukuhlelwa Kwemiqulu Emibili

Ama-weld rolls kufanele akwazi ukuvala ishubhu ngokucindezela okwanele ukucasula imiphetho ngisho noma i-welder ivaliwe futhi imiphetho iyabanda. Lokhu kudinga izingxenye ezinkulu ezivundlile zamandla njengoba kuphakanyiswe imicibisholo ku-Fig. 4-1. Indlela elula, eqondile yokuthola lawa mandla ukusebenzisa ama-side rolls amabili njengoba kusikiselwe ku-Fig. 4-2.

Ibhokisi elinama-roll amabili liyonga kakhulu ukuze lakhiwe. Kunesikulufu esisodwa kuphela esingalungiswa ngesikhathi sokugijima. Inezintambo zesandla sokudla nesobunxele, futhi inyakazisa amaroli amabili angene futhi aphume ndawonye. Leli lungiselelo lisetshenziswa kabanzi kuma-diameters amancane nezindonga ezincane. Ukwakhiwa kwamaroli amabili kunenzuzo ebalulekile yokuthi kuvumela ukusetshenziswa komumo womphimbo we-oval weld oyisicaba owathuthukiswa yi-THERMATOOL ukusiza ukuqinisekisa ukuthi imiphetho yeshubhu iyahambisana.

Ngaphansi kwezinye izimo ukuhlelwa kwama-roll amabili kungase kuthambekele ekubangeleni ama-swirl marks ku-tube. Isizathu esivamile salokhu ukwakheka okungalungile, okudinga ukuthi amaphethelo e-roll asebenze ngaphezu kwengcindezi evamile. Amamaki e-Swirl angase avele ngezinto zamandla aphezulu, ezidinga ukucindezela okuphezulu kwe-weld. Ukuhlanza njalo imiphetho ye-roll ngesondo le-flapper noma i-grinder kuzosiza ukunciphisa ukumaka.

Ukugaya amaroli ngenkathi kunyakaza kuzonciphisa amathuba okugaya noma ukucwilisa umqulu kodwa ukuqapha okukhulu kufanele kusetshenziswe lapho wenza kanjalo. Njalo yiba nomuntu omi eduze kwe-E-Stop uma kunesimo esiphuthumayo.

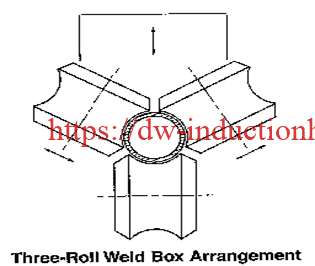

Ukuhlelwa Kwemiqulu Emithathu

Abaningi abasebenza ngomshini wokugaya bakhetha ukuhlelwa kwama-roll amathathu aboniswe ku-Fig. 4-3 ngeshubhu elincane (kufika cishe ku-4-1/2″OD). Inzuzo yayo enkulu phezu kokuhlelwa kwama-roll-roll ukuthi amamaki aphendukayo acishe aqedwe. Iphinde inikeze ukulungiswa kokulungisa ukubhaliswa konqenqema uma lokhu kudingekile.

Imiqulu emithathu, ihlukaniswe ngamadigri angu-120, ifakwe kuma-clevises kumsebenzi osindayo we-chuck wokuskrola wemihlathi emithathu. Zingalungiswa zingene futhi ziphume ndawonye ngesikulufu se-chuck. I-chuck ifakwe epuletini elingemuva eliqinile, elilungisekayo. Ukulungiswa kokuqala kwenziwa ngemiqulu emithathu evalwe ngokuqinile kupulaki eyenziwe ngomshini. I-back plate ilungiswa iqonde futhi ibheke eceleni ukuze ilethe i-roll engezansi ekuqondaneni okunembile nobude be-mill pass kanye ne-centerline ye-mill. Bese i-back plate ikhiywa ngokuvikelekile futhi ayidingi ukulungiswa kuze kube yilapho i-roll elandelayo ishintsha.

Ama-clevise abambe amaroli amabili angaphezulu afakwe kuma-radial slides anikezwe ngezikulufo zokulungisa. Noma iyiphi kulawa maroli amabili ingalungiswa ngawodwana. Lokhu kungeziwe ekulungiseni okuvamile kwamaroli amathathu ndawonye nge-skrola chuck.

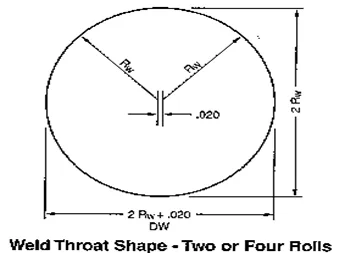

Ama-Roll Amabili - I-Roll Design

Ngethubhu engaphansi kwe-1.0 OD, kanye nebhokisi lama-roll amabili, umumo onconywayo uboniswa ku-Fig. 4-4. Lona umumo omuhle kakhulu. Inikeza ikhwalithi ye-weld engcono kakhulu kanye nesivinini esiphezulu se-weld. Ngaphezulu cishe kuka-1.0 OD, i-.020 offset iba yinto engasho lutho futhi ingase ishiywe, umqulu ngamunye usekelwe endaweni evamile.

Ama-Roll amathathu - I-Roll Design

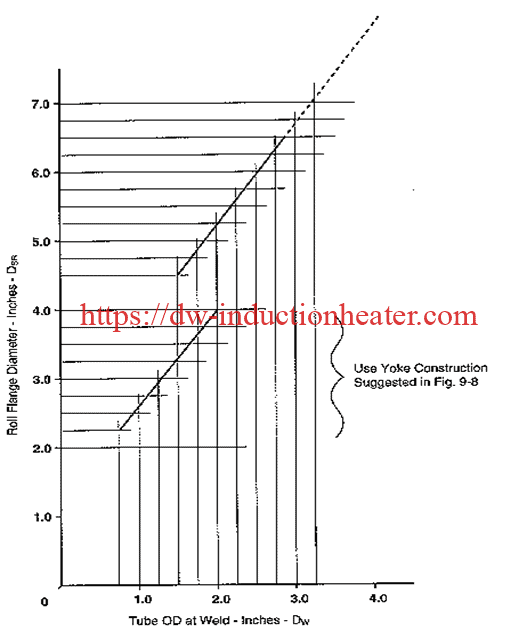

Imiphimbo yokushisela enamasondo amathathu ivamise ukuba yindilinga, enobubanzi be-DW obulingana nobubanzi beshubhu eliqediwe D kanye nesibonelelo sokulinganisa a

RW = DW/2

Njengebhokisi le-roll-roll, sebenzisa i-Fig. 4-5 njengesiqondiso sokukhetha ububanzi be-roll. Igebe eliphezulu kufanele libe ngu-.050 noma lilingane nodonga oluncane oluzosetshenziswa, kuye ngokuthi yikuphi okukhulu. Ezinye izikhala ezimbili kufanele zibe ngu-.060 umkhawulo, zikalwe zibe phansi ngokuthi .020 ezindongeni ezizacile kakhulu. Isincomo esifanayo mayelana nokunemba okwenziwa ebhokisini lama-roll amabili siyasebenza lapha.

I-FIN PASS YOKUGCINA

Izinhloso Zokudizayina

Umumo onconyiwe we-fin pass yokugcina ukhethwe ngezinjongo ezimbalwa:

- Ukwethula ishubhu kuma-weld rolls kwakhiwa irediyasi yonqenqema

- Ukuze ube nemiphetho ehambisanayo ku-vee

- Ukuhlinzeka ngokuvulwa kwe-vee okwanelisayo

- Ukuze ihambisane nomklamo we-weld roll ophakanyiswe ngaphambilini

- Ukuze kube lula ukugaya.

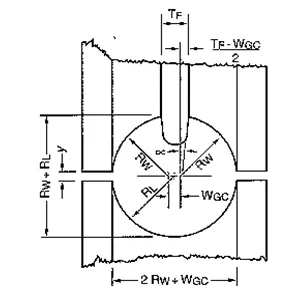

I-Fin Pass Shape yokugcina

Umumo onconywayo uboniswa ku-Fig. 4-6. Umqulu ongezansi unerediyasi engashintshi ukusuka endaweni eyodwa. Ngayinye yama-halves amabili aphezulu ane-radius engashintshi. Nokho, irediyasi ephezulu RW ayilingani neradiyasi yeroli engezansi engu-RL futhi izikhungo lapho irediya ephezulu iphansi isuswa eceleni ngebanga le-WGC. I-fin ngokwayo iboshwe nge-engeli.

Izindlela Zokuqamba

Ubukhulu bulungiswa ngemibandela emihlanu elandelayo:

- Irediya yokugaya ephezulu iyafana neradiyasi yokugaya i-weld roll RW.

- I-girth GF nkulu kune-GW ye-weld rolls ngenani elilingana nesibonelelo sokuminyanisa S.

- Ubukhulu be-TF bufana nokuthi ukuvulwa phakathi kwemiphetho kuzoba ngokuhambisana ne-Fig. 2-1.

- I-fin taper angle a iwukuthi imiphetho yeshubhu izoba yi-perpendicular to tangent.

- Isikhala y phakathi kwama-roll flange aphezulu naphansi sikhethwa ukuthi siqukathe umucu ngaphandle kokumaka kuyilapho ngesikhathi esifanayo sihlinzeka ngezinga elithile lokulungiswa kokusebenza.

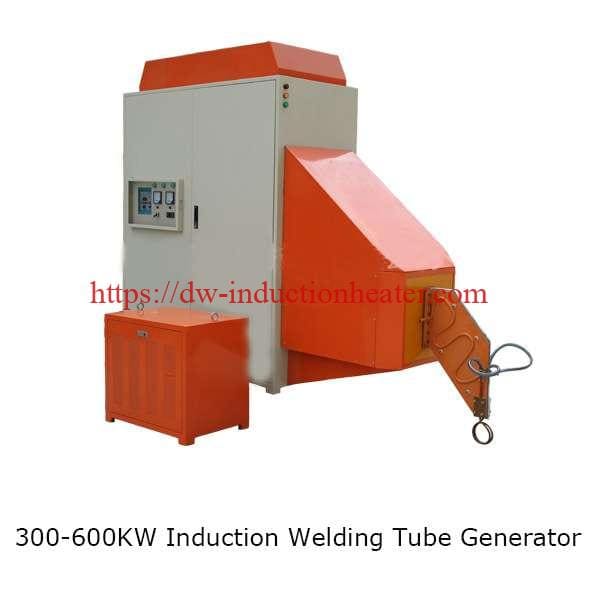

Izici Zobuchwepheshe Ze-High Frequency Induction Seam Welding Generator:

| Yonke I-Solid State (MOSFET) High Frequency Induction Tube kanye nomshini wokushisela wamapayipi | ||||||

| imodeli | GPWP-60 | GPWP-100 | GPWP-150 | GPWP-200 | GPWP-250 | GPWP-300 |

| amandla wokufaka | 60KW | 100KW | 150KW | 200KW | 250KW | 300KW |

| voltage Input | 3Izigaba, 380/400/480V | |||||

| DC Voltage | 0-250V | |||||

| DC yamanje | 0-300A | 0-500A | 800A | 1000A | 1250A | 1500A |

| imvamisa | I-200-500KHz | |||||

| Ukusebenza kahle komphumela | 85% -95% | |||||

| Isici samandla | Umthwalo ogcwele <0.88 | |||||

| Ukupholisa Umfutho Wamanzi | >0.3MPa | |||||

| Ukupholisa Ukugeleza Kwamanzi | >60L/min | >83L/min | >114L/min | >114L/min | >160L/min | >160L/min |

| Itlet lokushisa lamanzi | <35 ° C | |||||

Ukulungiswa kwamandla we-IGBT wesifunda sonke esiqinile kanye nobuchwepheshe bokulawula bamanje obuguquguqukayo, kusetshenziswa okuhlukile kwe-IGBT okushintshwa okuthambile kokunqunywa kwe-high-frequency kanye nokuhlunga kwe-amorphous ukulawula amandla, ukulawulwa kwe-inverter ye-IGBT enesivinini esikhulu nokunembayo, ukuze kuzuzwe u-100-800KHZ/ 3 -300KW umkhiqizo isicelo.

Ukulungiswa kwamandla we-IGBT wesifunda sonke esiqinile kanye nobuchwepheshe bokulawula bamanje obuguquguqukayo, kusetshenziswa okuhlukile kwe-IGBT okushintshwa okuthambile kokunqunywa kwe-high-frequency kanye nokuhlunga kwe-amorphous ukulawula amandla, ukulawulwa kwe-inverter ye-IGBT enesivinini esikhulu nokunembayo, ukuze kuzuzwe u-100-800KHZ/ 3 -300KW umkhiqizo isicelo.- Ama-capacitor anamandla amakhulu angenisiwe asetshenziselwa ukuthola imvamisa ye-resonant ezinzile, ukuthuthukisa ngempumelelo ikhwalithi yomkhiqizo, nokubona ukuzinza kwenqubo yamapayipi ashiselwe.

- Faka esikhundleni ubuchwepheshe bokulungisa amandla e-thyristor obujwayelekile ngobuchwepheshe bokulungisa amandla okusika ama-high-frequency ukuze ufinyelele ukulawulwa kwezinga le-microsecond, uqaphele kakhulu ukulungiswa okusheshayo nokuzinza kokuphuma kwamandla enqubo yepayipi lokushisela, ukuphuma kwe-ripple kuncane kakhulu, kanye ne-oscillation yamanje ezinzile. Ukushelela nokuqondile kwe-weld seam kuqinisekisiwe.

- Ezokuphepha. Ayikho imvamisa ephezulu kanye ne-voltage ephezulu ye-volts engu-10,000 kumishini, engagwema ngokuphumelelayo imisebe, ukuphazamiseka, ukukhishwa, ukuthungela nezinye izenzakalo.

- Inekhono eliqinile lokumelana nokuguquguquka kwamandla kagesi wenethiwekhi.

- Inesici samandla aphezulu kulo lonke uhla lwamandla, olungasindisa ngempumelelo amandla.

- Ukusebenza kahle okuphezulu nokonga amandla. Imishini isebenzisa ubuchwepheshe bokushintshwa okuthambile obunamandla amakhulu ukusuka kokokufaka kuye kokukhiphayo, okunciphisa ukulahleka kwamandla futhi ithole ukusebenza kahle kukagesi okuphakeme kakhulu, futhi inamandla aphezulu kakhulu ebangeni lamandla aphelele, ewonga ngempumelelo amandla, ahluke kwendabuko Uma kuqhathaniswa neshubhu. thayipha imvamisa ephezulu, ingasindisa u-30-40% womphumela wokonga amandla.

- Imishini i-miniaturized futhi ihlanganiswe, okusindisa kakhulu indawo ehlala kuyo. Izinto zokusebenza azidingi isiguquli esisuka phansi, futhi asidingi i-inductance enkulu yokuvama kwamandla ukuze kulungiswe i-SCR. Isakhiwo esincane esihlanganisiwe siletha lula ukufakwa, ukulungiswa, ukuthutha, nokulungiswa.

- Ibanga lemvamisa lika-200-500KHZ libona ukushiselwa kwamapayipi ensimbi nensimbi engagqwali.

I-High Frequency Induction Tube kanye ne-Pipe Welding Solutions