I-Induction Hardening Surface Process Applictons

Kuyini ukuqina kwe-induction?

Ukuqeda ukuqina kuyindlela yokwelashwa kokushisa lapho ingxenye yensimbi enokuqukethwe okwanele kwekhabhoni ifudunyezwa emkhakheni wokungeniswa bese ipholile ngokushesha. Lokhu kwandisa kokubili ubulukhuni nobulukhuni bengxenye. Ukushisa kwe-induction kukuvumela ukuthi ube nokushisa okwenziwe endaweni okushisayo okunqunywe kusengaphambili futhi kukuvumela ukuthi ulawule ngokunembile inqubo yokuqina. Inqubo yokuphindeka ngaleyo ndlela iqinisekisiwe. Imvamisa, ukuqina kwe-induction kusetshenziswa ezingxenyeni zensimbi okudingeka zibe nokumelana okukhulu kokugqokwa komhlaba, ngenkathi ngasikhathi sinye zigcina izakhiwo zazo zomshini. Ngemuva kokuthi inqubo yokuqiniswa kwe-induction isitholakele, into yokusebenza yensimbi idinga ukucinywa emanzini, uwoyela noma i-inorder yangaphakathi ukuthola izakhiwo ezithile zesendlalelo saphezulu.

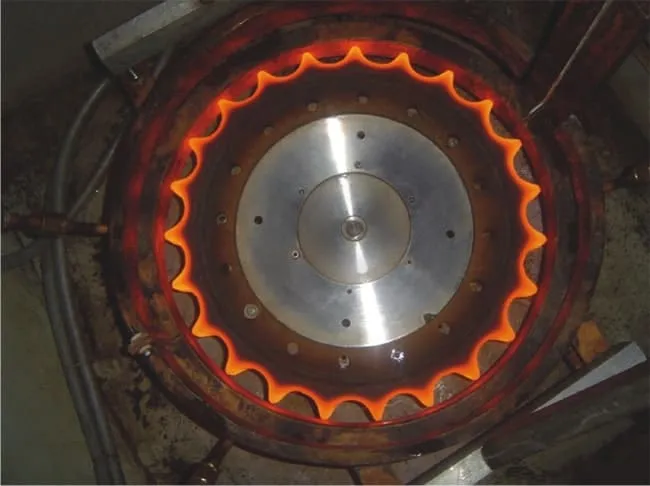

Ukuqeda ukuqina kuyindlela yokuqinisa ngokushesha nangokukhetha ubuso bengxenye yensimbi. Ikhoyili yethusi ephethe izinga elibonakalayo lokushintshana kwamanje ibekwa eduze (ingathinti) ingxenye. Ukushisa kwenziwa, futhi eduze nobuso ngokulahleka kwe-eddy yamanje kanye ne-hysteresis. Ukucima, imvamisa kususelwa emanzini ngokufaka okufana ne-polymer, kubhekiswa engxenyeni noma kucwilisiwe. Lokhu kuguqula isakhiwo sibe yi-martensite, esinzima kakhulu kunesakhiwo sangaphambilini.

Uhlobo oludumile, lwesimanjemanje lwemishini yokwenza lukhuni ibizwa ngokuthi isithwebuli. Ingxenye ibanjwa phakathi kwezikhungo, ijikelezwe, futhi idluliswe kwekhoyili eqhubekayo enikezela ukushisa nokucisha. Ukucisha kuqondiswe ngaphansi kwekhoyili, ngakho-ke noma iyiphi indawo enikezwe ingxenye ipholile ngokushesha ngemuva kokushisa. Izinga lamandla, isikhathi sokuhlala, isilinganiso se-scan (feed) nezinye izinqubo eziguquguqukayo zilawulwa kahle yikhompyutha.

Inqubo yokuqinisa ikesi esetshenziselwa ukukhulisa ukumelana nokugqoka, ukuqina kobuso kanye nempilo yokukhathala ngokwakhiwa kwesendlalelo sendawo eqinisiwe ngenkathi kugcinwa isakhiwo semvelo esingathinteki.

Ukuqeda ukuqina isetshenziselwa ukukhulisa izakhiwo zemishini yezakhi zensimbi endaweni ethile. Izicelo ezijwayelekile yi-powertrain, ukumiswa, izingxenye zenjini nezitembu. Ukuqiniswa kwe-induction kuhle kakhulu ekulungiseni izimangalo zewaranti / ukwehluleka kwensimu. Izinzuzo eziyinhloko ukuthuthuka kwamandla, ukukhathala nokuqina kokugqoka endaweni enendawo ngaphandle kokuyakha kabusha leyo nto.

Izinqubo Nezimboni ezingazuza ekuqiniseni kokungeniswa:

-

Ukwelashwa ngokushisa

-

Ukuqina kwamaketanga

-

Ukuqina kwe-Tube & Pipe

-

Ukwakha umkhumbi

-

I-Aerospace

-

Isitimela

-

Izithuthi

-

Amandla avuselelekayo

Izinzuzo ze-Induction Hardening:

Kuthandelwe izakhi ezingaphansi kokulayishwa okunzima. Induction inikezela ngobulukhuni obuphezulu ngebhokisi elijulile elikwazi ukuphatha imithwalo ephezulu kakhulu. Amandla okukhathala andiswa ngokwakhiwa komgogodla othambile ozungezwe ungqimba lwangaphandle olunzima kakhulu. Lezi zakhiwo ziyathandeka ezingxenyeni ezihlangabezana nokulayishwa kwe-torsional kanye nezindawo ezihlangabezana namandla emandla. Ukucutshungulwa kwe-induction kwenziwa ingxenye eyodwa ngasikhathi esivumela ukunyakaza kobukhulu obubonakalayo kusuka engxenyeni kuye engxenyeni.

-

Ukulawulwa okuqondile kokushisa nokuqina kokuqina

-

Ukushisa okulawulwayo nokwenziwe kwasendaweni

-

Ihlanganiswe kalula emigqeni yokukhiqiza

-

Inqubo esheshayo nephindaphindwayo

-

Umsebenzi ngamunye ungenziwa lukhuni ngamapharamitha anembile

-

Inqubo eyonga ugesi

Izinsimbi zensimbi nezinsimbi ezingenasici ezingasetshenziswa zibe lukhuni ngokungeniswa:

Ama-fasteners, ama-flanges, amagiya, amabhere, ithubhu, izinhlanga zangaphakathi nezangaphandle, ama-crankshafts, ama-camshafts, amajoka, imishayo yokushayela, imishayo yokukhipha, okokuphotha, imigoqo ye-torsion, izindandatho zokubulala, izintambo, ama-valve, ama-rock drill, njll.

Ukwenyuka Kwe-Wear Resistance

Kukhona ukuhlobana okuqondile phakathi kobulukhuni nokuqina kokugqoka. Ukumelana kokugqoka kwengxenye kukhuphuka kakhulu ngokuqina kwe-induction, kucatshangelwa ukuthi isimo sokuqala sokwaziswa senziwe sancishwa, noma saphathwa saba sesimweni esithambile.

Amandla Akhuphukile Nokukhathala Ngenxa Yesixazululo Esicindezelayo Esicindezelayo Se-Core Core & Residual ku-Surface

Ukucindezela okucindezelayo (okuvame ukubhekwa njengesici esihle) kungumphumela wesakhiwo esiqinile eduze kwendawo ehlala ivolumu ethe xaxa kunokwakheka okuyisisekelo nokwangaphambilini.

Izingxenye zingafuthelana ngemuva Ukukhishwa Kwesivinini Ukulungisa Izinga Lokuqina, njengoba ufisa

Njenganoma iyiphi inqubo ekhiqiza isakhiwo se-martensitic, i-tempering izokwehlisa ubunzima ngenkathi kunciphisa ubungqabavu.

Icala elijulile ngeCore Tough

Ukujula kwamacala okujwayelekile kungu-.030 ”- .120” okujule ngokwesilinganiso kunezinqubo ezinjenge-carburizing, i-carbonitriding, nezinhlobo ezahlukahlukene ze-nitriding ezenziwa emazingeni okushisa abucayi. Kumaphrojekthi athile afana nama-axels, noma izingxenye ezisasebenziseka noma ngabe impahla eningi seyigugile, ukujula kwamacala kungaba ngama-½ intshi noma ngaphezulu.

Inqubo yokukhetha ukuqina engenakho ukufihla okudingekayo

Izindawo ezine-post-welding noma i-post-machining zihlala zithambile - zimbalwa kakhulu ezinye izinqubo zokuphatha ukushisa ezikwazi ukufeza lokhu.

Ukuhlanekezelwa Okuncane

Isibonelo: umphini ongu-1 "Ø x 40" omude, onamaphephabhuku amabili ahlukaniswe ngokulinganayo, ngamunye u-2 ”omude odinga ukuxhaswa komthwalo futhi ugqoke ukumelana. Ukuqiniswa kwe-induction kwenziwa kulezi zindawo nje, ubude obungu-4 ”. Ngendlela ejwayelekile (noma uma ukungeniswa kubuqedile bonke ubude balolo daba), kuzoba ne-warpage ethe xaxa.

Ivumela ukusetshenziswa kwama-Steels wezindleko eziphansi njenge-1045

Insimbi ethandwa kakhulu esetshenziselwa izingxenye ezizongeniswa ziqinile ngu-1045. Iyashesha ukuwuthutha, ibize kancane, futhi ngenxa yokuqukethwe kwekhabhoni engu-0.45% ngegama nje, ingahle ibe yi-induction eyenziwe yaqina yaba ngu-58 HRC +. Ibuye ibe nengozi ephansi yokuqhekeka ngesikhathi sokwelashwa. Ezinye izinto ezithandwayo zale nqubo zingu-1141/1144, 4140, 4340, ETD150, nezinsimbi ezahlukahlukene.

Imikhawulo ye-Induction Hardening

Kudinga i-Induction Coil kanye ne-Tooling okuphathelene neGeometry yengxenye

Njengoba ibanga lokuhlanganisa i-part-to-coil libalulekile ekusebenzeni kahle kokushisa, ubukhulu bekhoyili nentaba kumele kukhethwe ngokucophelela. Ngenkathi abaphathi abaningi benenqwaba yamakhoyili ayisisekelo wokushisa imilo eyindilinga efana nemiphini, amaphini, ama-roller njll., Amanye amaphrojekthi angadinga ikhoyili yangokwezifiso, kwesinye isikhathi kubiza izinkulungwane zamaRandi. Kumaphrojekthi wevolumu ephakathi nendawo kuya phezulu, inzuzo yezindleko zokwelashwa ezincishisiwe ingxenye ngayinye ingaqeda izindleko zekhoyili kalula. Kwezinye izimo, izinzuzo zobunjiniyela zenqubo zingadlula ukukhathazeka kwezindleko. Ngaphandle kwalokho, kumaphrojekthi wevolumu ephansi ikhoyili nezindleko zamathuluzi kuvamise ukwenza inqubo ingasebenzi uma kufanele kwakhiwe ikhoyili entsha. Ingxenye kufanele futhi isekelwe ngandlela thile ngesikhathi sokwelashwa. Ukugijima phakathi kwezikhungo kuyindlela ethandwayo yezingxenye zohlobo lwe-shaft, kepha kwezinye izimo eziningi ukusebenzisa amathuluzi ngokwezifiso kufanele kusetshenziswe.

Amathuba amakhulu okuqhekeka kuqhathaniswa nezinqubo eziningi zokwelashwa kokushisa

Lokhu kungenxa yokufudumeza nokucisha okusheshayo, futhi nokuthambekela kokudala izindawo ezishisayo kuzimpawu / emaphethelweni njenge: keyways, grooves, cross hole, threads.

Ukuphazamiseka ne-Induction Hardening

Izinga lokuhlanekezela livame ukuba likhulu kunezinqubo ezifana ne-ion noma i-nitriding yegesi, ngenxa yokushisa / ukucima okusheshayo kanye noguquko lwe-martensitic. Uma kushiwo lokho, ukuqina kwe-induction kungaveza ukuphazamiseka okuncane kunokwelashwa okuvamile, ikakhulukazi uma kusetshenziswa kuphela endaweni ekhethiwe.

Ukulinganiselwa Kwezinto nge-Induction Hardening

Kusukela inqubo yokwenza lukhuni akuvamisile ukubandakanya ukusakazeka kwekhabhoni noma ezinye izinto, okokusebenza kufanele kuqukathe ikhabhoni eyanele kanye nezinye izinto ukuhlinzeka ukuqina okusekela ukuguqulwa kwemartensitic kufinyelele ezingeni lobulukhuni obufunwayo. Lokhu kusho ukuthi ikhabhoni ikububanzi obungu-0.40% +, okuveza ubulukhuni buka-56-65 HRC. Izinto ezisezingeni eliphansi zekhabhoni ezinjenge-8620 zingasetshenziswa ngokuncipha komphumela wobulukhuni obungafinyeleleka (40-45 HRC kuleli cala). Izinsimbi ezinjenge-1008, 1010, 12L14, 1117 ngokuvamile azisetshenziswa ngenxa yokwanda okulinganiselwe kobulukhuni obufinyelelekayo.

Imininingwane Yokucubungula Indawo Yokungenisa

Ukuqeda ukuqina inqubo esetshenziselwa ukuqina kwensimbi nezinye izinto ze-alloy. Izingxenye ezizophathwa ukushiswa zifakwa ngaphakathi kwekhoyili yethusi bese zifudunyezwa ngaphezu kwezinga lokushisa lazo lokuguqula ngokusebenzisa i-current eshintshanayo kwekhoyili. Isikhathi esishintshashintshayo kwikhoyili senza intambo yomazibuthe eshintshanayo engxenyeni yomsebenzi edala ukuthi ingxenye engaphandle yengxenye ishise ibe sezingeni lokushisa elingaphezu kwebanga lenguquko.

Izingxenye zifudunyezwa kusetshenziswa enye insimu kazibuthe iye ezingeni lokushisa ngaphakathi noma ngaphezulu kwebanga lenguquko elandelwa ukuqedwa ngokushesha. Kuyinqubo ye-electromagnetic kusetshenziswa ikhoyili ye-inductor yethusi, ephakelwa i-current ezingeni elithile lobubanzi namandla.