Induction Ukushisa Plate Yensimbi YOKWAKHA

Incazelo

Induction Ukushisa Plate Yensimbi YOKWAKHA NOKWAKHA OKUSHESHAYO

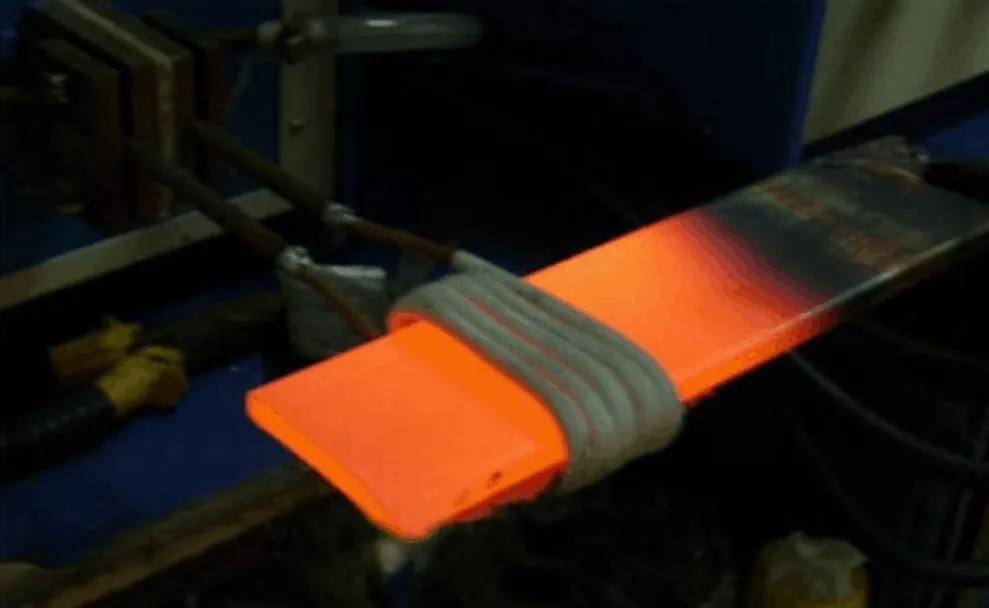

I-metal induction yokushisa ipuleti yensimbi yokwakha futhi ukwakheka okushisayo izinhlelo ezinhle kakhulu zokushisa ukufakwa. Ezezimboni Ukwenziwa kwe-induction nokwakha okushisayo izinqubo zibandakanya ukugoba noma ukubumba i-billet yensimbi noma ukuqhakaza ngemuva kokuthi kufudunyezwe ezingeni lokushisa lapho ukumelana kwalo ne-deformation kubuthakathaka. Amabhulokhi wezinto ezingekho kwensimbi angasetshenziswa futhi.

Ukushisa imishini yokushisa noma izimpahla ezijwayelekile zisetshenziselwa inqubo yokuqala yokushisa. Amabhola angahanjiswa nge-inductor nge-pneumatic noma i-hydraulic pusher; i-pinch roller drive; umshayeli ogandaganda; noma ugongolo lokuhamba. Ama-pyrometers angaxhumani nawo asetshenziselwa ukukala izinga lokushisa le-billet.

Eminye imishini efana nemishini yokunyakaza yomshini, imishini yokugoba, nemishini yokuphrinta ye-hydraulic extrusion isetshenziselwa ukugoba noma ukubumba insimbi.

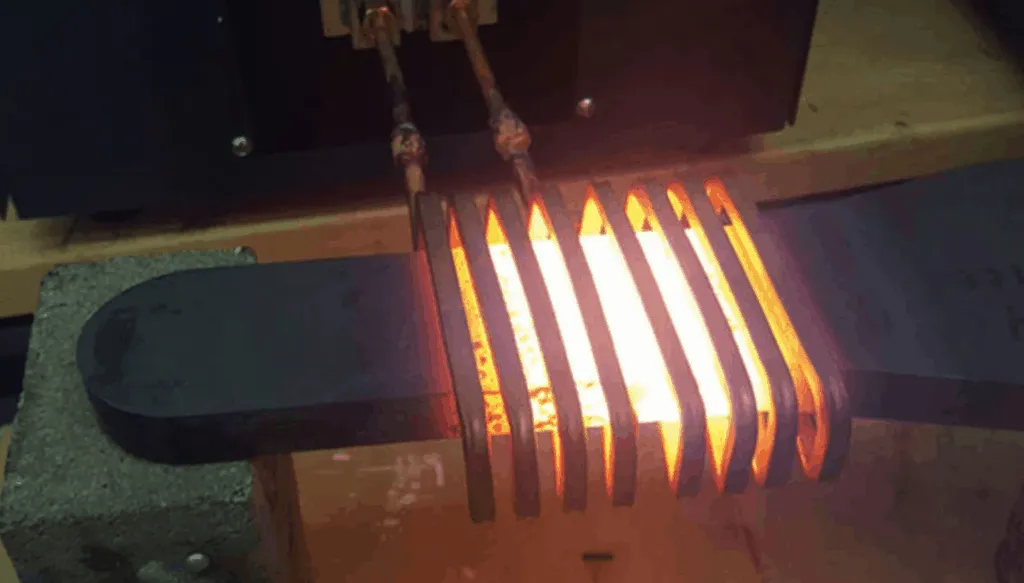

Injongo: Hlangisa ipuleti lensimbi (3.9 ”x 7.5” x 0.75 ”/ 100mm x 190mm x 19mm) ngaphambi kokwenza inhloko yekhanda ngenhloso yokukhulisa umkhiqizo uma kuqhathaniswa nokushisa ngomlilo wegesi.

Material: Ipuleti yensimbi

Ukushisa: I-2192 ºF (1200 ºC)

Ukuvama: 7 kHz

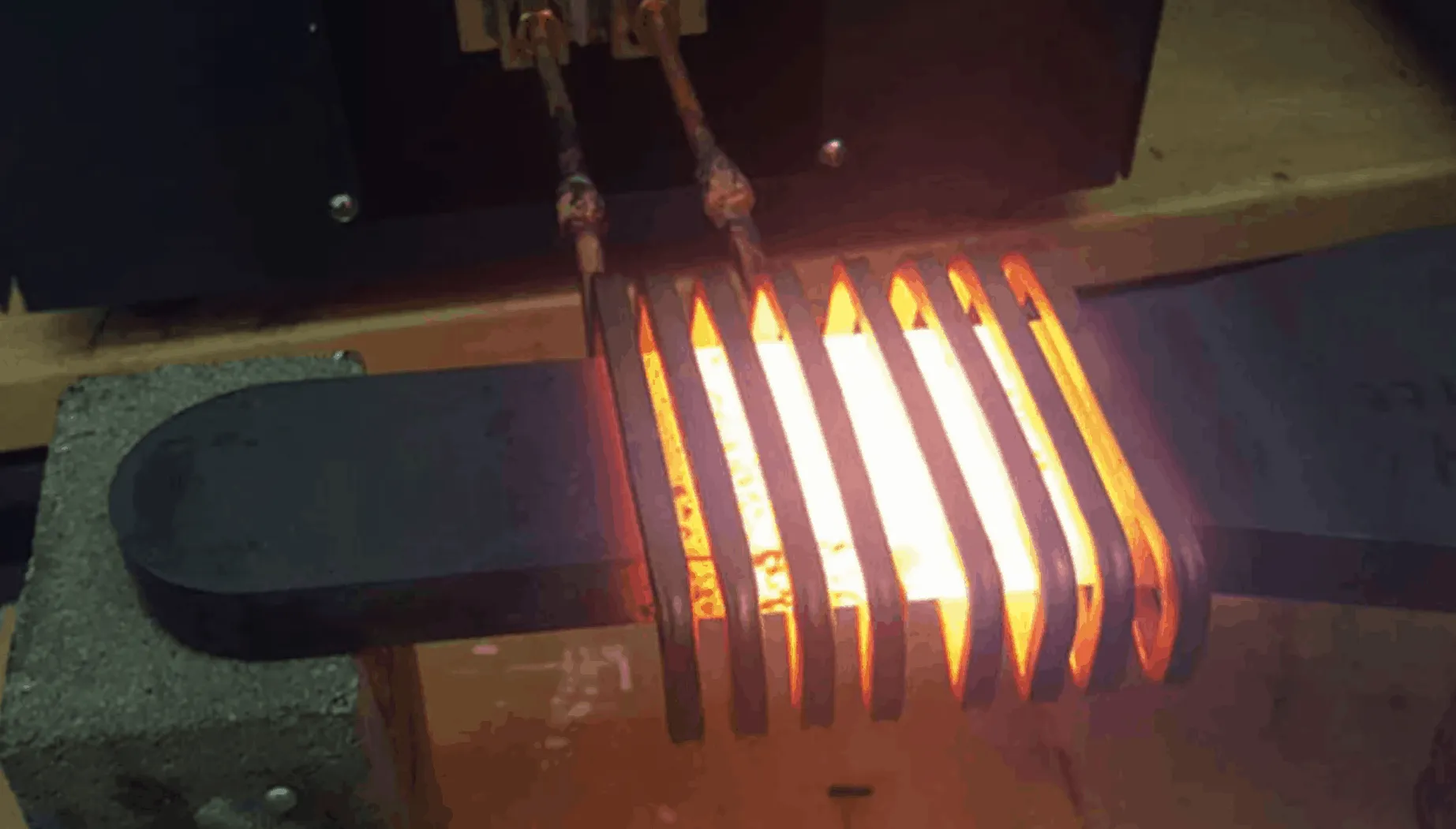

Izisetshenziswa Zokushisa Zokungenisa: I-DW-MF-125/100, 125 kW ukufakwa kokushisa uhlelo ifakwe isiteshi sokushisa esikude esiqukethe ama-capacitor amathathu we-26.8 μF.

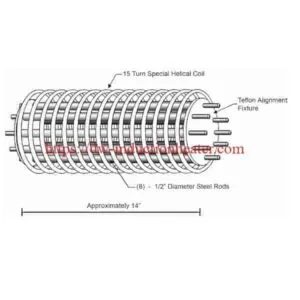

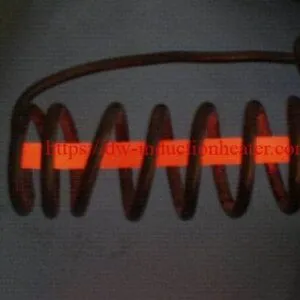

- Isikhundla ezintathu, ikhoyili yama-helical eguquguqukayo eyenzelwe futhi yathuthukiswa ukukhiqiza ukushisa okudingekayo kwalolu hlelo lokusebenza.

Inqubo Ingcwecwe yensimbi yafakwa kuzindawo ezintathu zekhoyili yama-helical kanye namandla kagesi avulwa. Ngemizuzwana engama-37, kufakwe ipuleti lesibili lensimbi engagqwali, kwathi ngemizuzwana engama-75 kwafakwa ipuleti lesithathu lensimbi engagqwali. Ngemizuzwana eyi-115, izinga lokushisa elifunekayo litholakele ingxenye yokuqala, futhi inqubo yaqhubeka.

Ngemuva kokuqalisa, izingxenye zingafudunyezwa njalo ngemizuzwana engama-37 kusukela kulandelana ezifakiwe. Ngenkathi isikhathi esiphelele somjikelezo singu-115

imizuzwana, ingxenye ingasuswa njalo ngemizuzwana engama-37, evumele ukuthi kungeniswe ukuze kufinyelele izinga lokukhiqiza elifunekayo

futhi ubone ukuzuza okukhulu uma kuqhathaniswa nokusebenzisa isithando segesi.

Imiphumela / Izinzuzo

Izinga lokukhiqiza eliphakeme: Le nqubo izuze izinga lokukhiqiza lezingxenye eziyi-100 ngehora, kanti isithando somlilo sikhiqiza izingxenye ezingama-83 ngehora

- Ukuphindeka: Le nqubo iyaphindwa futhi ingahlanganiswa nenqubo yokukhiqiza

- Precision kanye nekghono: Ukushisa kunembile futhi kusebenza kahle, ngokushisa kusetshenziswe kuphela kumacwecwe ensimbi

Ukushisa okushisa okushisa okusetshenziselwa ukukhiqizwa kwezimboni zezimboni kakhulu:

• I-Steel 1200º C • I-Brass 750º C • I-Aluminium 550º C

Izicelo Eziphelele Zokwenza Induction

Imishini yokushisa induction ijwayele ukusetshenziselwa ukushisa ama-billet wensimbi, imigoqo, amabhlokhi ethusi, ne-titanium block ekushiseni okufanele kokukhula nokwakha.

Izicelo Zokwakha Ngokwengxenye

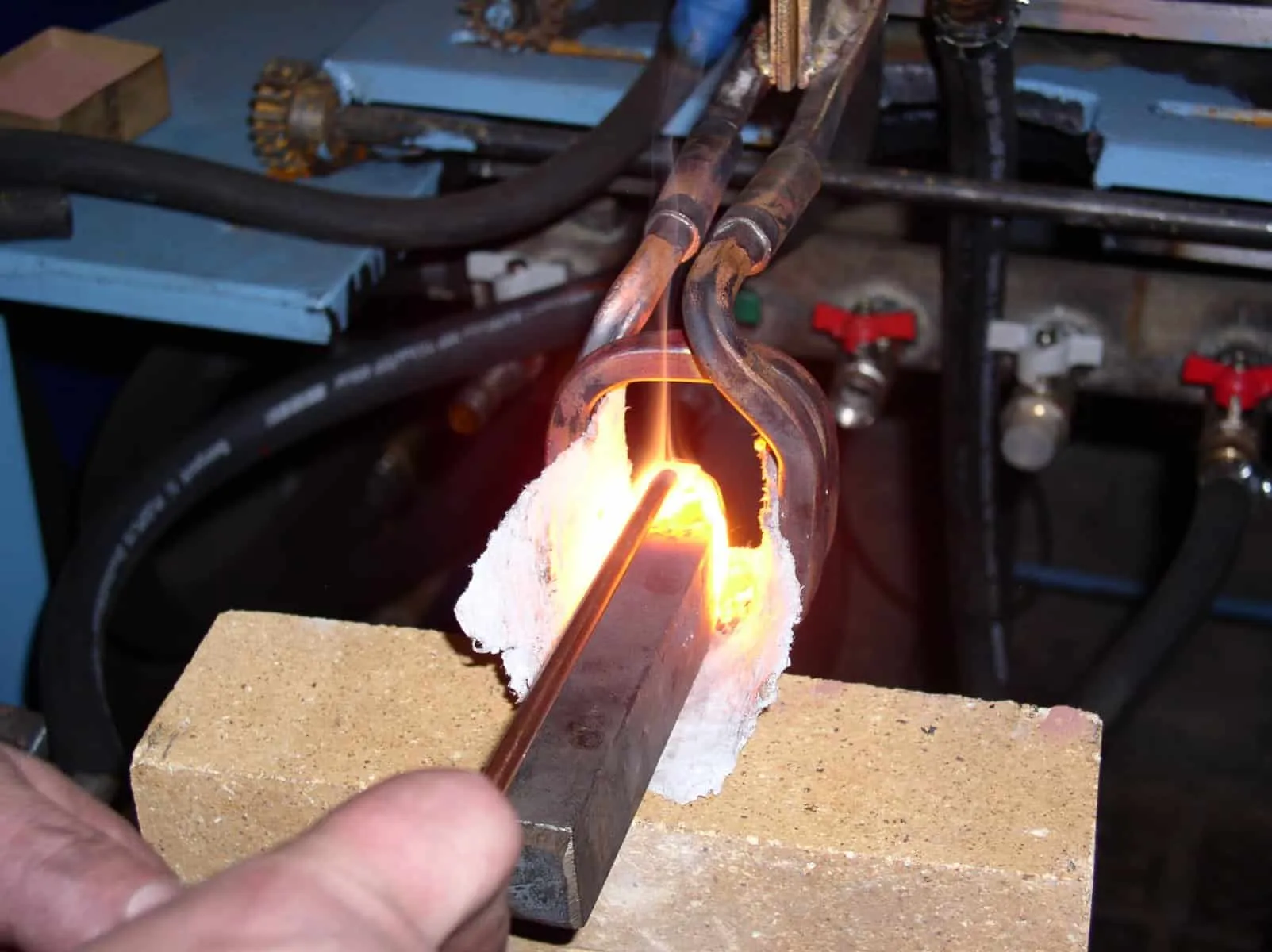

Ukushisa induction kusetshenziselwa ukufudumeza izingxenye ezinjengeziphetho zamapayipi, iziphetho zama-axle, izingxenye zezimoto, nemigoqo yebha yokuqamba ngokwenqubo nezinqubo ezakhiwe.

I-Induction Heating Advantage

Uma kuqhathaniswa nokufakelwa okuvamile, imishini yokufudumeza yokungeniswa yokwenza inika inqubo nenzuzo enhle

Izikhathi ezifudumeza eziningi ezifushane, kunciphisa ukukalwa ne-oxidation

Ukulawulwa kokushisa okulula nokunembile. Izingxenye emazingeni okushisa angaphandle okucacisiwe zingatholwa futhi zisuswe

Akunasikhathi esilahlekile sokulinda isithando somlilo silinganisele ekushiseni okudingakalayo

I-Automated imishini yokushisa engenayo kudinga umsebenzi wezandla omncane

Ukushisa kungaqondiswa endaweni eyodwa, okubaluleke kakhulu ezingxenyeni ezinendawo eyodwa yokwakha.

Ukusebenza okuhle kakhulu kokushisa - ukushisa kwenziwa engxenyeni uqobo futhi akudingeki ukuthi kufudunyezwe egumbini elikhulu.

Izimo zokusebenza ezingcono. Ukuphela kokushisa okukhona emoyeni yilokho kwezingxenye ngokwazo. Izimo zokusebenza zimnandi kakhulu kunesithando sikaphethiloli.