1200°C – 1800°C mpo Hlukanisa ishubhu lomlilo-izinga lokushisa eliphezulu lomlilo we-tubular

Incazelo

Iyini ishubhu yomlilo ehlukanisiwe eqondile?

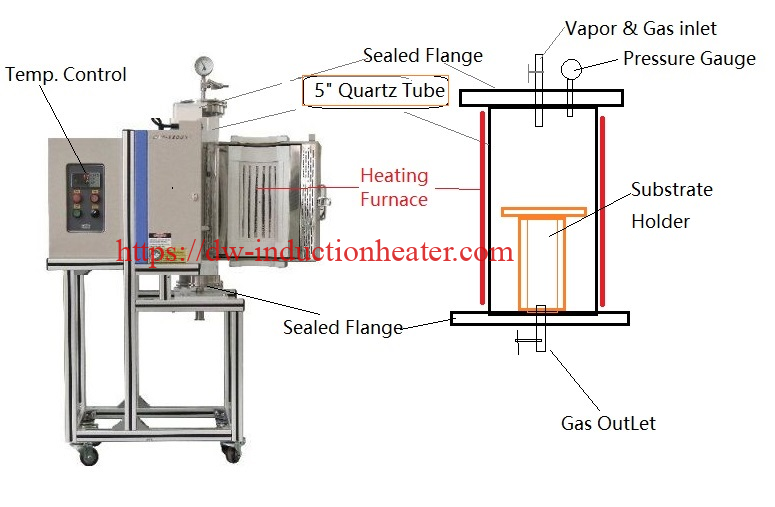

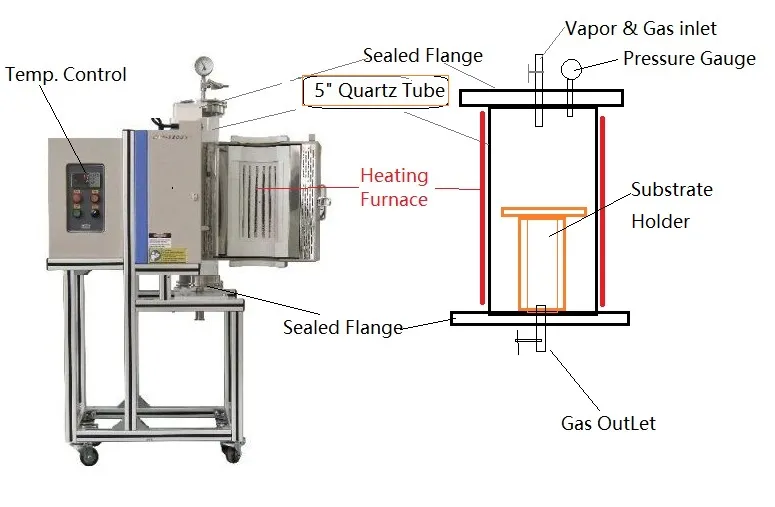

A isithando somlilo esihlukanisiwe esime mpo wuhlobo lwesithando somlilo esinegumbi lokufudumeza elibheke mpo, elihlukaniswa libe izingxenye ezimbili. Lo mklamo uvumela ukulayishwa kalula nokulayishwa kwamasampula noma izinto zokwakha esithandweni somlilo.

Isithando somlilo esihlukanisiwe ngokuvamile siqukethe igumbi lokushisa eliyicylindrical, elenziwe ngezinto eziphikisayo ezifana ne-alumina noma i-quartz. Isici sokushisa siboshwe ngaphandle kwekamelo ukuze kunikeze ukufudumeza okufanayo.

Umklamo we-split tube uvumela ukufinyelela okulula ekamelweni lokushisa. Ingxenye eyodwa yegumbi ingavulwa, ngokuzenzela noma ngomshini ohamba ngemoto, ukuze kufakwe kalula futhi kukhishwe amasampula noma izinto zokwakha. Lokhu kubaluleke kakhulu ezinqubweni ezidinga ukulayishwa nokulayishwa njalo noma ezivivinyweni ezibandakanya amasampuli amaningi.

Isithando somlilo seshubhu ehlukanisiwe sivame ukusetshenziswa ezindaweni zokucwaninga kanye nezicelo zezimboni zezinqubo ezihlukahlukene zokwelashwa kokushisa okufana ne-annealing, sintering, kanye ne-brazing. Ibuye idume kwisayensi yezinto zokwakha kanye ne-metallurgy yokufunda izakhiwo zezinto ezahlukahlukene emazingeni okushisa aphezulu.

Izibonelo Isicelo

ukunamathela, carbonisation, crystal ukukhula, debinding, degassing, drying, glowing, harding, metal injection molding (MIM), pyrolyses, rapid prototyping, sintering, sublimation, synthesis, tempering

Izici ezijwayelekile

- 1800 °C izinga lokushisa eliphezulu lokusebenza

- Ukupholisa umoya kwegobolondo lezendlalelo ezimbili kuqinisekisa izinga lokushisa elingaphansi kuka-45℃

- Ukunemba kwezinga lokushisa: ±1℃; Izinga lokushisa elifanayo: ± 1℃ (Isisekelo kusayizi wendawo yokushisisa)

- ezihlakaniphile zamanje kanye voltage imitha lokushisa isilawuli, kulula ukuyisebenzisa, Programmable

- Ilungiselelwe ukusetshenziswa okuqondile

- Ukushisa okuphansi kwe-ceramic fiber insulation

- Ilenga iqonde, izakhi zokushisisa ze-MoSi2 zekhwalithi ephezulu

- Ukuvikela iluphu ephindwe kabili (ngaphezu kwamanje, izinga lokushisa elingaphezulu nangaphezulu kwe-voltage njll)

- Insimbi, i-quartz, i-Corundum materials ingakhethwa njenge-tube material

- Idigri ye-vacuum ingaba -0.1Mpa

I-Spes:

| Temperature | 1200 ℃ | 1400 ℃ | 1600 ℃ | 1700 ℃ | 1800 ℃ |

| I-Voltage AC | 220V / 380V | 220V / 380V | 220V / 380V | 220V / 380V | 220V / 380V |

| Ukushisa okusebenzayo kwesikhathi eside | 1150 ℃ | 1350 ℃ | 1550 ℃ | 1650 ℃ | 1750 ℃ |

| Ukulawula ukulawula izinga lokushisa | ± 1 ℃ | ||||

| Impahla yeshubhu yomlilo | Ishubhu yensimbi engagqwali/quartz glass tube/corundum tube | i-corundum tube | |||

| Izinga lokushisa elifanayo esithandweni somlilo | ±1℃ (kuya ngosayizi wegumbi lokufudumeza) Ukulawula izinga lokushisa kwamaphuzu amaningi kungasetshenziswa uma kudingeka izidingo eziphezulu | ||||

| Isici sokulinganisa izinga lokushisa nobubanzi bokulinganisa izinga lokushisa | Ibanga lezinga lokushisa le-nickel chromium nickel silicon K elingu-0-1350℃ | Uhlobo lwe-S | Uhlobo B | ||

| Inombolo yamasegimenti ejika ahleliwe | Iqembu elilodwa linamasegimenti angama-50, elesibili linezigaba ezingama-22, kanti elesithathu linamasegimenti ayi-8. | ||||

| Izinga lokushisa | Ilungiseka ukusuka ku-1℃/h ukuya ku-40℃/min | ||||

| Isici sokushisa | I-silicon carbide induku | I-silicon carbide induku | I-silicon molybdenum induku | ||

| Indawo yesici sokushisa | Indawo yokufaka izungeza ishubhu yesithando somlilo futhi ivundlile kushubhu yesithando somlilo. | ||||

| Izinto zokukhomba | Ukuhlanzeka okuphezulu kwe-alumina fiber board | ||||

| Ububanzi bewaranti nesikhathi | Isithando somlilo sikagesi sinewaranti yamahhala yonyaka owodwa. Isici sokushisa neshubhu yesithando somlilo azikho ngaphansi kwewaranti (isici sokushisa sizoshintshwa mahhala uma sonakaliswe ngokwemvelo phakathi nezinyanga ezintathu). | ||||

| Izingxenye ezisele ezingahleliwe | Izinto ezimbili zokufudumeza, amasethi amabili ezinti, incwadi eyodwa yeziqondiso, isitifiketi esisodwa sokuvumelana, isitini esisodwa sokuvala umnyango wesithando somlilo, iphinifa elilodwa le-crucible, iglavu elilodwa elinokushisa okuphezulu, i-crucible eyodwa ekhethekile yesithando somlilo, nezindandatho ezimbili zokuvala | ||||

Ekuphetheni, i isithando somlilo esihlukanisiwe esime mpo iyithuluzi elibalulekile labacwaningi, onjiniyela, nabakhiqizi abadinga amakhono anembayo nanokwethenjelwa okushisisa izinga lokushisa eliphezulu. Ukwakhiwa kwayo okuqinile, idizayini eguquguqukayo, ukulawula izinga lokushisa okunembayo, nezici zokuphepha kuyenza ibe ucezu lwesisetshenziswa esibalulekile sohlelo olubanzi lwezinhlelo zokusebenza ezimbonini ezifana nesayensi yezinto zokwakha, i-metallurgy, i-semiconductor processing, nokunye. Njengoba ubuchwepheshe buqhubeka buthuthuka, singalindela ukuthuthuka okwengeziwe ekwakhiweni nasekusebenzeni kwesithando somlilo esihlukanisiwe esiqondile, okuholela ekusebenzeni kahle okukhulu nakakhulu nasekusebenzeni ekucubunguleni nasekuhloleni izinga lokushisa eliphezulu.

Ekuphetheni, i isithando somlilo esihlukanisiwe esime mpo iyithuluzi elibalulekile labacwaningi, onjiniyela, nabakhiqizi abadinga amakhono anembayo nanokwethenjelwa okushisisa izinga lokushisa eliphezulu. Ukwakhiwa kwayo okuqinile, idizayini eguquguqukayo, ukulawula izinga lokushisa okunembayo, nezici zokuphepha kuyenza ibe ucezu lwesisetshenziswa esibalulekile sohlelo olubanzi lwezinhlelo zokusebenza ezimbonini ezifana nesayensi yezinto zokwakha, i-metallurgy, i-semiconductor processing, nokunye. Njengoba ubuchwepheshe buqhubeka buthuthuka, singalindela ukuthuthuka okwengeziwe ekwakhiweni nasekusebenzeni kwesithando somlilo esihlukanisiwe esiqondile, okuholela ekusebenzeni kahle okukhulu nakakhulu nasekusebenzeni ekucubunguleni nasekuhloleni izinga lokushisa eliphezulu.