I-Vacuum Sintering Furnace-I-High Temperature Vacuum Atmosphere Sintering Furnace

Incazelo

I-Vacuum Sintering Furnace / I-Vacuum Atmosphere Sintering Furnace iwucezu olukhethekile lwemishini esetshenziswa ekwenziweni nasekucutshungulweni kwezinto, ikakhulukazi emkhakheni we-metallurgy nezitsha zobumba. Lolu hlobo lwesithando somlilo ludizayinelwe ukudala indawo enezimo zomoya ezilawulwayo, ngokuvamile ezibandakanya ukucindezela okuphansi kanye nezakhi ezithile zegesi, ukuze kuzuzwe imiphumela enembile yokushisa.

Isicelo:

Umkhathi we-carbon-free, i-metal injection molding (MIM), i-metalization, i-sintering, i-Superhard alloy, imikhiqizo ye-graphite, njll.

Izici ezijwayelekile

- Izithando zomlilo zinikeza umoya ochazwe ngokunembile onokuhlanzeka okuphezulu kakhulu

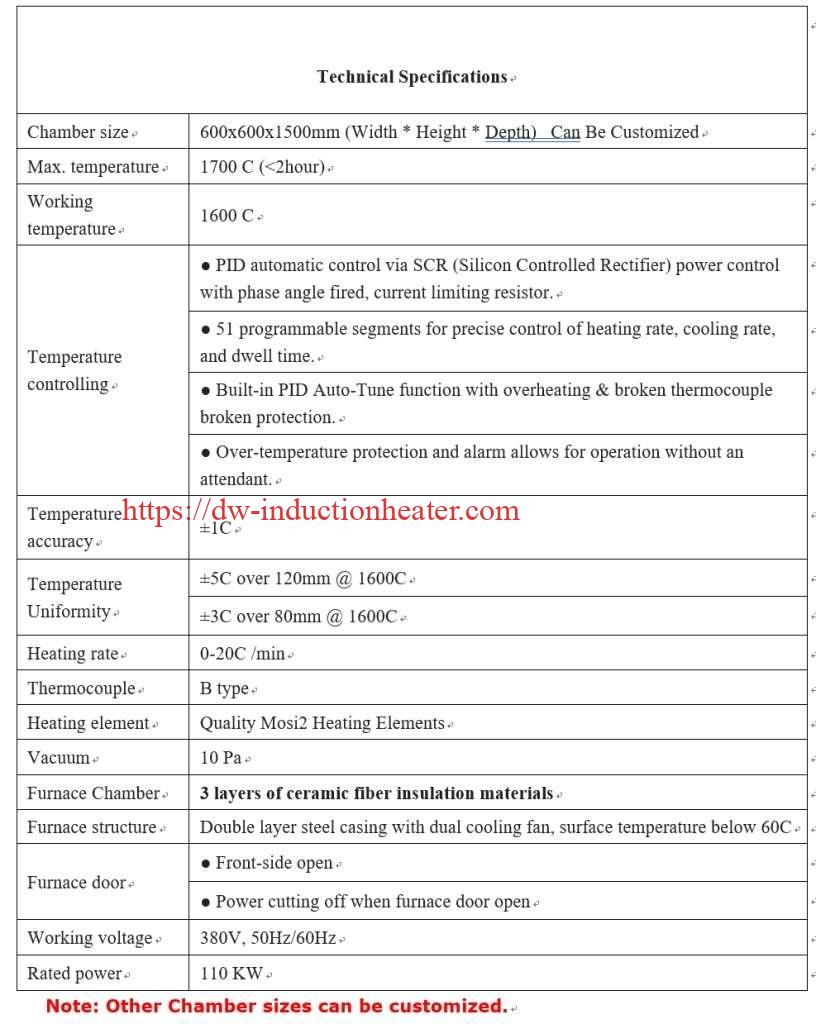

- Idigri ye-vacuum ephezulu ukuya ku--0.01Pa

- Amazinga aphezulu okushisa afika ku-1700c

- Ukubuka kwangaphakathi kwekhamera yezinga lokushisa eliphezulu kuyenzeka

- Izithando zomlilo zinikeza i-vacuum engcono kakhulu

- Ukusebenza kokucindezela kwengxenye ye-hydrogen uma iceliwe

- Izivinini zokumpompa i-vacuum ezilawulwa ngokunembile ezifanele izimpushana

- Ukurekhodwa kwedatha yokuphathwa kwekhwalithi

- Ukuvikela ingcindezi

- Umthelela omncane womkhathi

- Isakhiwo sokupholisa: Umoya + Ukupholisa Amanzi

- Ukuvikelwa kwe-loop yesendlalelo esikabili. (Ukuvikelwa ngaphezu kwezinga lokushisa, ukuvikelwa kokunikezwa kwamandla nokunye)

- Ukulawula isikrini sokuthinta

Isb. Isithando somlilo esenziwe ngokwezifiso:

I-Sintering iyinqubo yokuhlanganisa nokwenza inqwaba yezinto eziqinile ngokushisa kanye/noma ukucindezela ngaphandle kokuyincibilikisa kuze kufike lapho kuncibilika khona. Le nqubo ivame ukusetshenziswa ekukhiqizeni izingxenye zensimbi eziyimpuphu, izitsha zobumba, nezinye izinto lapho kudingeka khona amandla aphezulu nokunemba. I-vacuum atmosphere sintering furnaces idlala indima ebalulekile ekuzuzeni izakhiwo ezifiselekayo kanye nekhwalithi yokugcina yomkhiqizo.

I-Sintering iyinqubo yokuhlanganisa nokwenza inqwaba yezinto eziqinile ngokushisa kanye/noma ukucindezela ngaphandle kokuyincibilikisa kuze kufike lapho kuncibilika khona. Le nqubo ivame ukusetshenziswa ekukhiqizeni izingxenye zensimbi eziyimpuphu, izitsha zobumba, nezinye izinto lapho kudingeka khona amandla aphezulu nokunemba. I-vacuum atmosphere sintering furnaces idlala indima ebalulekile ekuzuzeni izakhiwo ezifiselekayo kanye nekhwalithi yokugcina yomkhiqizo.

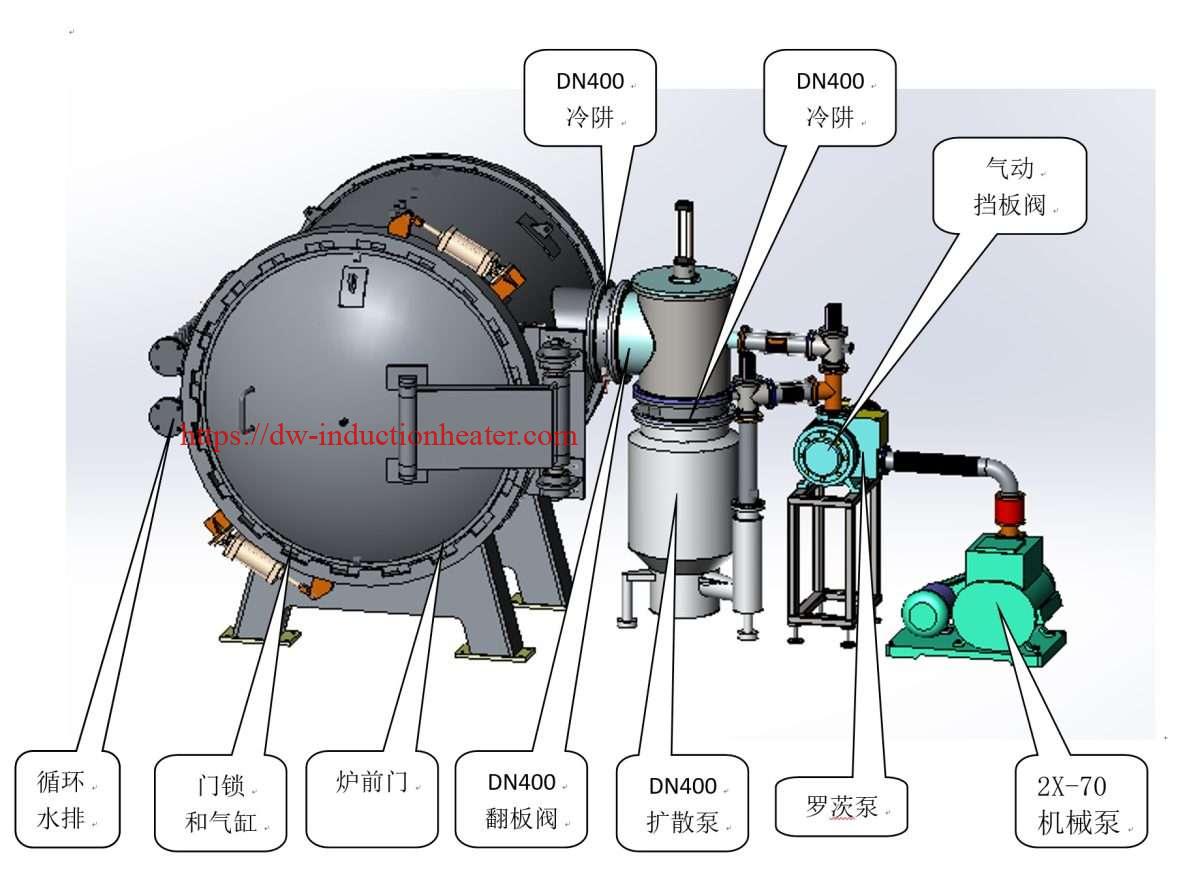

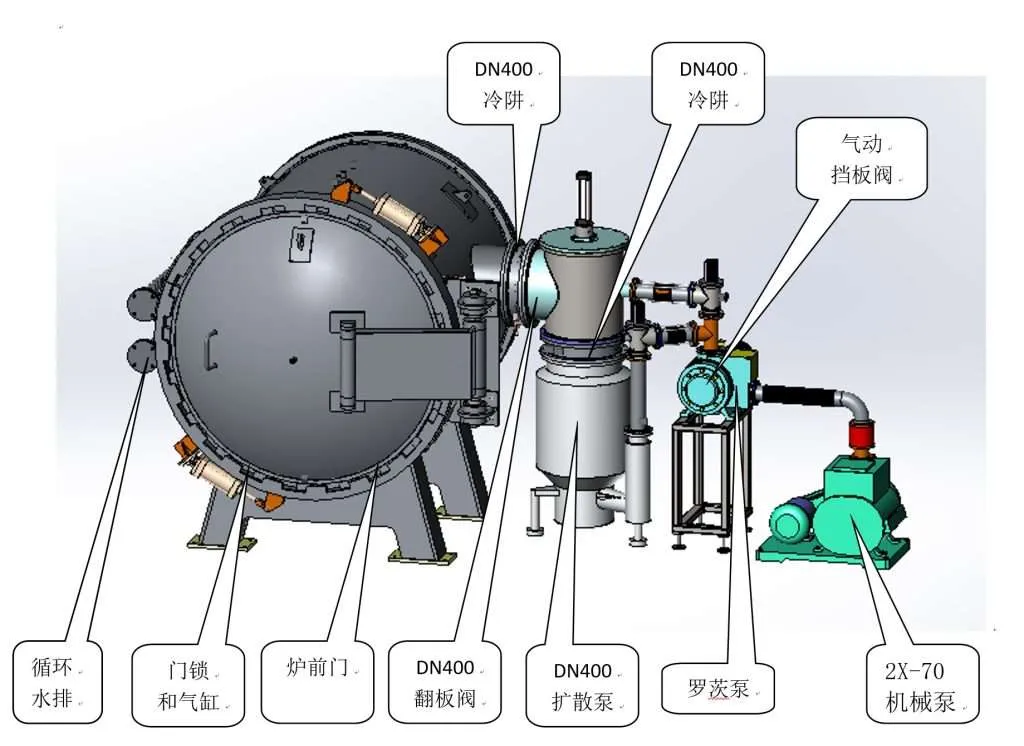

Izingxenye ezibalulekile ze-a i-vacuum atmosphere sintering othandweni kufaka phakathi ikamelo le-vacuum, izinto zokufudumeza, izinhlelo zokuhlinzeka ngegesi, amasistimu okulawula izinga lokushisa, kanye nezinto zokufakelwa. Igumbi le-vacuum liyindawo evalekile lapho inqubo ye-sintering yenzeka ngaphansi kwezimo zokucindezela okuphansi. Lokhu kusiza ukuvimbela i-oxidation kanye nokungcoliswa kwezinto ezicutshungulwayo, okubalulekile ekuzuzeni imikhiqizo yekhwalithi ephezulu ye-sintered.

Izinto zokushisisa zinesibopho sokuhlinzeka ngamandla okushisa adingekayo ukuze kukhushulwe izinga lokushisa ngaphakathi kwesithando kumazinga adingekayo ekushiseni. Lezi zakhi ziklanywe ngokucophelela ukuze kuqinisekiswe ukushisisa okufanayo kulo lonke igumbi le-sintering, okubalulekile ukuze kuzuzwe imiphumela engaguquki kuyo yonke inqwaba yezinto ezicutshungulwayo.

Amasistimu wokuphakela igesi asetshenziselwa ukwethula amagesi athile ekamelweni lokucwilisa ukuze enze isimo esifiselekayo senqubo yokucwilisa. Amagesi avamile asetshenziswa ku-vacuum atmosphere sintering ahlanganisa i-hydrogen, i-nitrogen, i-argon, negesi yokwakha (ingxube ye-hydrogen ne-nitrogen). Ukulawulwa okunembile kokwakheka kwegesi nokucindezela kubalulekile ukuze kuzuzwe izinto ezibonakalayo ezifiselekayo kanye nokuvimbela ukusabela okungadingeki phakathi nenqubo ye-sintering.

Amasistimu okulawula izinga lokushisa abalulekile ekugcineni amaphrofayili okushisa anembile kuyo yonke inqubo ye-sintering. Lawa masistimu ngokuvamile ahlanganisa ama-thermocouples, izilawuli zezinga lokushisa, kanye nokushintshwa kwamandla kwesici sokushisisa ukuze kuqinisekiswe ukuthi izinto ezicutshungulwayo zingaphansi kwezimo ezinembile zokushisa ezidingekayo ukuze kufakwe i-sintering ngempumelelo.

Izinto zokufaka i-insulation zisetshenziselwa ukunciphisa ukulahleka kokushisa okuvela egunjini le-sintering kanye nokuhlinzeka ngokuvikela okushisayo kwendawo ezungezile. Lokhu kusiza ukuthuthukisa ukusebenza kahle kwamandla nokugcina izimo zokusebenza ezinzile ngaphakathi kwesithando somlilo.

Ukusebenza kwe-vacuum atmosphere isithando somlilo kuhilela izinyathelo ezimbalwa ezibalulekile. Okokuqala, izinto ezizofakwa esithandweni zilayishwa ekamelweni lomlilo, elibe selivalwa futhi likhishwe ukuze kwakhiwe indawo enengcindezi ephansi. Uma izinga le-vacuum elifiswayo selifinyelelwe, izinto zokushisisa ziyavulwa ukuze zikhuphule izinga lokushisa ngaphakathi kwegumbi liye ezingeni lokushisa elidingekayo le-sintering. Ngesikhathi esifanayo, amagesi athile angeniswa ekamelweni ukuze enze isimo esifunayo senqubo ye-sintering. Izinga lokushisa kanye nokwakheka kwegesi kulawulwa ngokucophelela kuwo wonke umjikelezo we-sintering ukuze kuqinisekiswe ukuthi izinto zenza izinguquko ezidingekayo zokushisa kanye namakhemikhali ukuze kuzuzwe izakhiwo ezifunwayo.

Izinzuzo zokusebenzisa a i-vacuum atmosphere sintering othandweni zihlanganisa ukulawula okunembile phezu kwenqubo ye-sintering, okuholela emikhiqizweni yekhwalithi ephezulu enezakhiwo ezifanayo. Ikhono lokudala izimo ezithile zomkhathi livumela ukucutshungulwa kwezinto ezifanelana nawe, njengokunciphisa i-oxidation, ukulawula ukukhula okusanhlamvu, nokukhuthaza ukuguqulwa kwesigaba esithile. Ukwengeza, ukusetshenziswa kwendawo ye-vacuum kunganciphisa ukungcoliswa futhi kuthuthukise ukuhlanzeka okuphelele kwezinto ezifakiwe.

Kafushane, i-vacuum sintering furnace-i-vacuum atmosphere sintering othandweni ucezu oluyinkimbinkimbi lwemishini edlala indima ebalulekile ekukhiqizeni izinto ezisezingeni eliphezulu ze-sintered. Ngokuhlinzeka ngezimo zomoya ezilawulwayo, ukulawulwa okunembile kwezinga lokushisa, nokushisa okufanayo, lezi ziko zenza abakhiqizi bathole imiphumela engaguquki nethembekile ekukhiqizeni izingxenye zensimbi eziyimpuphu, izitsha zobumba, nezinye izinto eziphambili.

I-Vacuum Atmosphere Furnace En