Ama-Basics Brazing Basics ngokujoyina ithusi, isiliva, ubhontshisi, insimbi nensimbi engagqwali, njll.

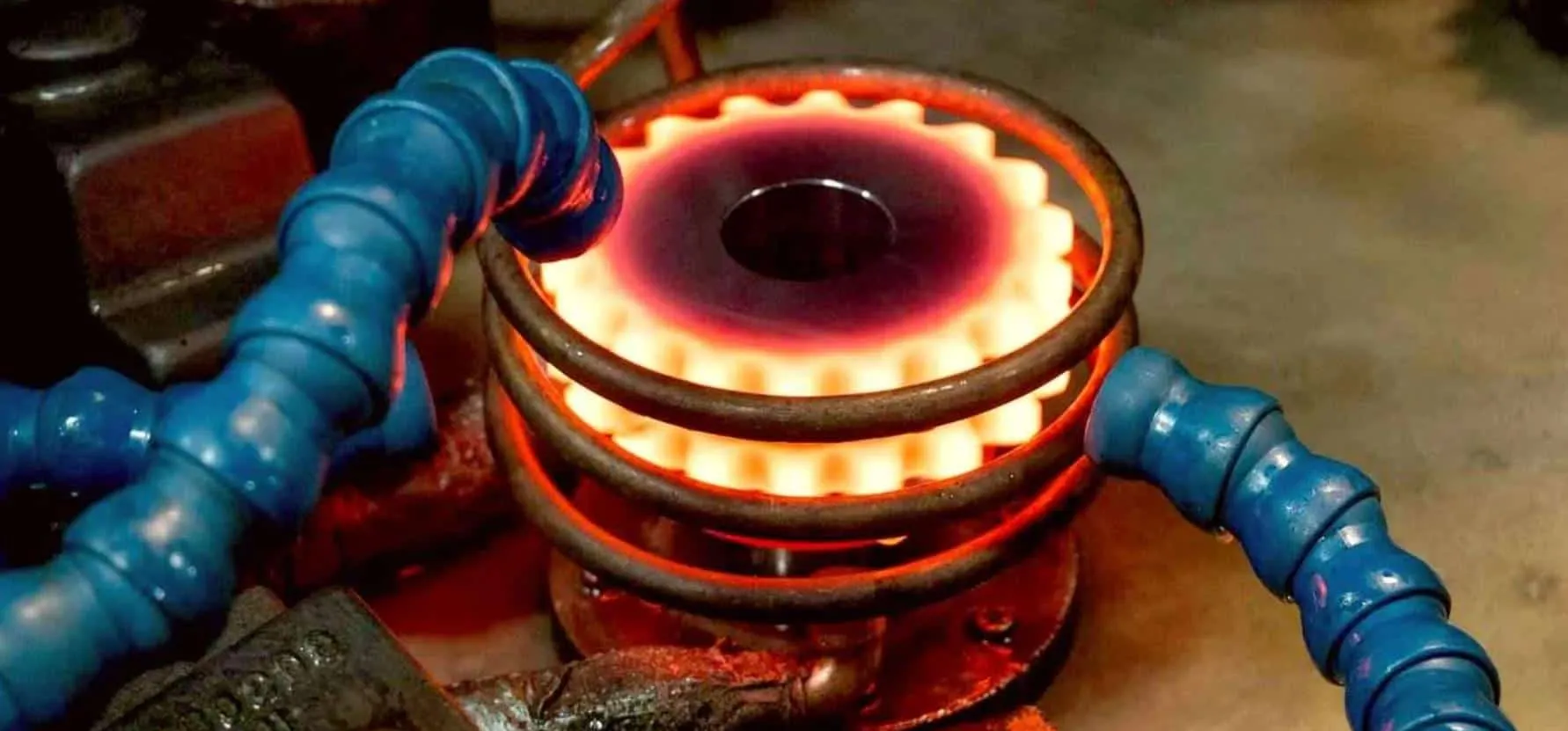

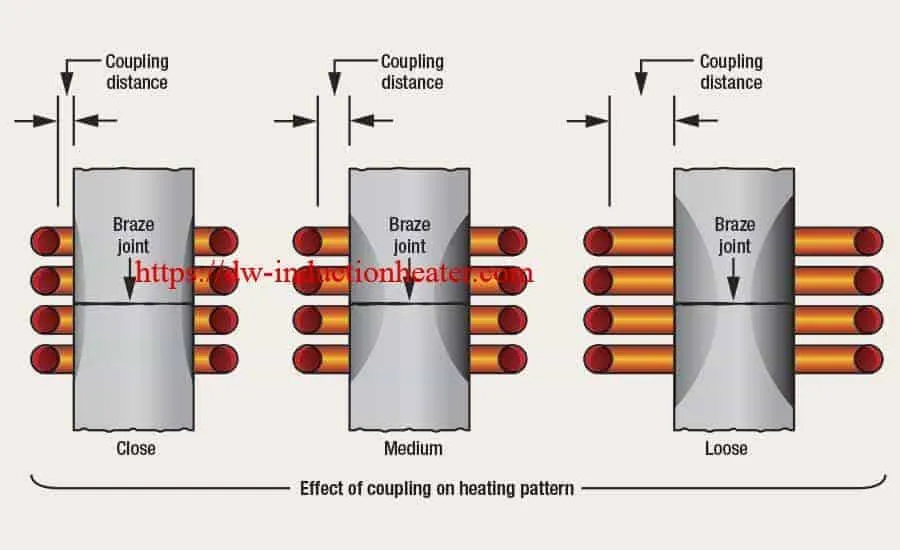

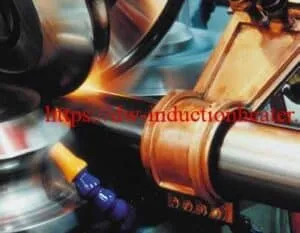

I-Induction Brazing isebenzisa ukushisa nensimbi yokugcwalisa ukujoyina izinsimbi. Uma sekuncibilikile, ukugcwaliswa kugobhoza phakathi kwezinsimbi eziseduze (izingcezu ziyahlanganiswa) nge-capillary action. I-filler encibilikayo ihlangana noqweqwe oluncane lwensimbi eyisisekelo ukwakha inhlanganisela eqinile, evuzayo. Imithombo ehlukene yokushisa ingasetshenziselwa ukubhontshisa: ukufakwa kokungeniswa kanye nokumelana nokushisa, ama-ovini, izithando, izibani, njll. Kunezindlela ezintathu ezivamile zokubopha: i-capillary, notch nokubumba. Ukubanjwa kwe-induction kukhathazeke kuphela okokuqala kwalokhu. Ukuba negebe elifanele phakathi kwezinsimbi eziyisisekelo kubalulekile. Igebe elikhulu kakhulu linganciphisa amandla we-capillary futhi liholele kumajoyini abuthakathaka kanye ne-porosity. Ukunwetshwa okushisayo kusho ukuthi izikhala kufanele zibalwe ngezinsimbi ekubhuliseni, hhayi endaweni, emazingeni okushisa. Isikhala esihle ngokujwayelekile si-0.05 mm - 0.1 mm. Ngaphambi kokuthi ubhodlise iBrazing ayinankinga. Kepha eminye imibuzo kufanele iphenywe - futhi iphendulwe - ukuze kuqinisekiswe ukujoyina okuphumelelayo, okungabizi kakhulu. Isibonelo: Zifanele kangakanani izinsimbi eziyisisekelo zokubopha; yini idizayini enhle kakhulu yekhoyili yesikhathi esithile nezidingo zekhwalithi; ngabe ukubopha kufanele kube okwenziwa ngezandla noma okuzenzakalelayo?

E-DAWEI Induction siphendula lawa namanye amaphuzu abalulekile ngaphambi kokuphakamisa isisombululo se-brazing. Gxila ezintweni ezigelezayo ze-Base izinsimbi kumele zivame ukufakwa ne-solvent eyaziwa ngokuthi yi-flux ngaphambi kokuba iboshwe. I-Flux ihlanza insimbi eyisisekelo, ivimbela i-oxidation entsha, futhi imanzise indawo yokubheda ngaphambi kokubopha. Kubalulekile ukufaka ukucucuza okwanele; kuncane kakhulu futhi ukugeleza kungaba

igcwele ama-oxide futhi ilahlekelwe amandla ayo okuvikela izinsimbi eziyisisekelo. I-flux ayidingeki njalo. Ukugcwalisa okune-phosphorus

ingasetshenziselwa ukubopha ama-alloys ethusi, ithusi nethusi. Ukuboshwa okungenayo i-flux nakho kungenzeka ngama-atmospheres asebenzayo kanye nama-vacuum, kepha ukubopha kufanele kwenziwe egumbini lomoya elilawulwayo. I-flux kufanele isuswe engxenyeni lapho ukufakwa kwensimbi sekuqinile. Kusetshenziswa izindlela ezahlukahlukene zokususa, okuvame kakhulu ukucisha amanzi, ukukha amanzi nokuxubha ucingo.